Novel multifunctional macromolecule based multilayer electromagnetic shielding material and preparation method thereof

An electromagnetic shielding material, polymer-based technology, applied in the fields of magnetic field/electric field shielding, layered products, chemical instruments and methods, etc., can solve the problems of single function, poor shielding effect, difficult to design morphological structure, etc., and achieve a simple preparation method. , High production efficiency, the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) The raw material is thermoplastic polyurethane (TPU) (58A, BASF), carbon nanotube (CNT), intumescent flame retardant (IFR), the conductive functional layer is carbon nanotube filled thermoplastic polyurethane, and the composite functional layer is carbon nanotube Composite filled thermoplastic polyurethane with intumescent flame retardant. The raw materials were dried in a vacuum oven at 80 °C for 24 h to remove moisture before use. First prepare the conductive functional layer and composite functional layer masterbatch, melt and mix the dried TPU and CNT in a twin-screw extruder at a temperature of 185°C, and prepare a TPU / CNT composite masterbatch containing 6wt% CNT ;The dried TPU, CNT, and IFR were melted, mixed and granulated in a twin-screw extruder at a temperature of 185°C to prepare a TPU / CNT / IFR composite masterbatch containing 1wt%CNT and 30wt%IFR;

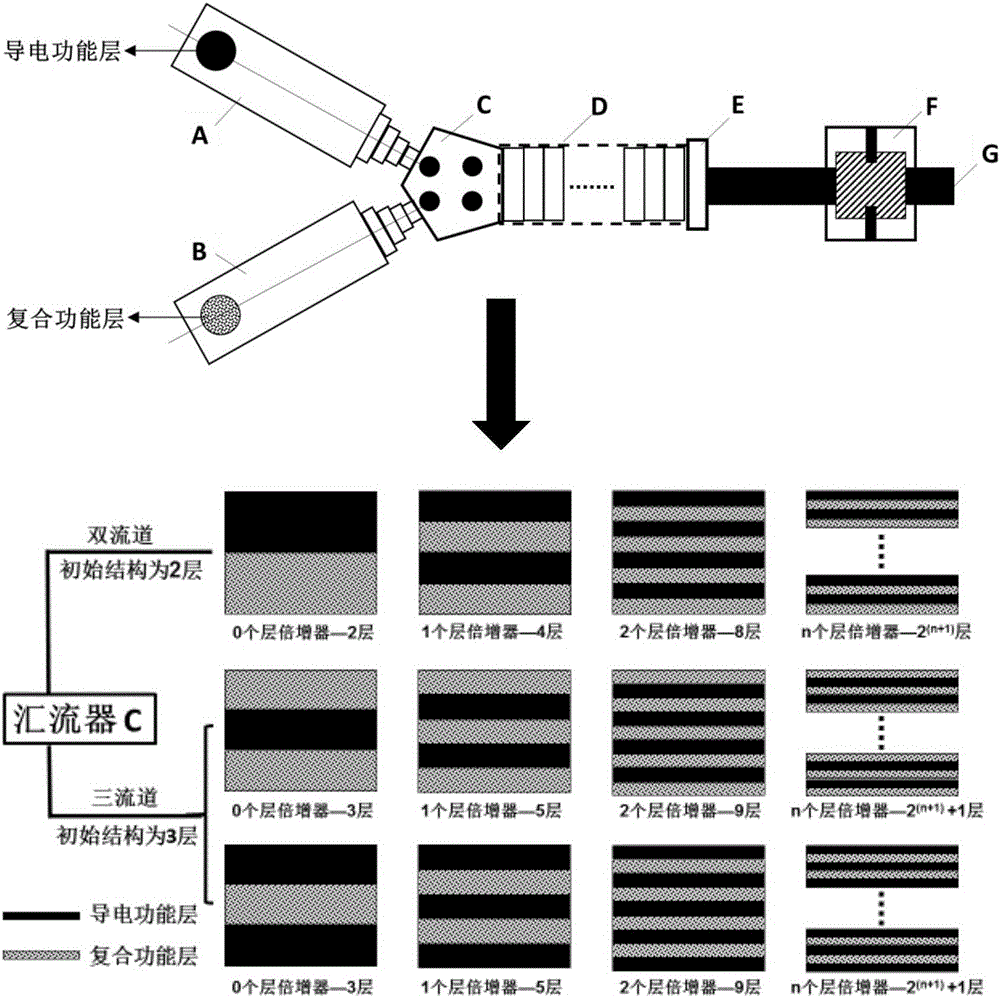

[0030] (2) Put the conductive functional layer and composite functional layer masterbatch into the two ex...

Embodiment 2

[0034] (1) The raw materials are polypropylene (PP), carbon black (CB), and nano-montmorillonite (MMT), the conductive functional layer is carbon black-filled polypropylene, and the composite functional layer is composite-filled polypropylene with carbon black and nano-montmorillonite . The raw materials were dried in a vacuum oven at 80 °C for 24 h to remove moisture before use. First prepare the conductive functional layer and composite functional layer masterbatch, melt and mix the dried PP and CB in a twin-screw extruder at a temperature of 200°C to prepare a PP / CB composite masterbatch containing 15wt% CB ;The dried PP, CB, and MMT were melt-mixed and granulated in a twin-screw extruder at a temperature of 200°C to prepare a PP / CB / MMT composite masterbatch containing 15wt%CB and 20wt%MMT;

[0035] (2) Put the conductive functional layer and composite functional layer masterbatch into the two extruders (A, B) of the multi-layer extrusion system respectively (see figure 1...

Embodiment 3

[0039] (1) The raw materials are polyethylene (PE), graphene (Gr), intumescent flame retardant (IFR), the conductive functional layer is graphene-filled polyethylene, and the composite functional layer is composite filled with graphene and intumescent flame retardant polyethylene. The raw materials were dried in a vacuum oven at 80 °C for 24 h to remove moisture before use. First prepare the conductive functional layer and composite functional layer masterbatch, melt and mix the dried PE and Gr in a twin-screw extruder at a temperature of 200°C to prepare a PE / Gr composite masterbatch containing 4wt%Gr ; The dried PE, Gr, and IFR were melt-mixed and granulated in a twin-screw extruder at a temperature of 200°C to prepare a PE / Gr / IFR composite masterbatch containing 4wt%Gr and 20wt%IFR;

[0040] (2) Put the conductive functional layer and composite functional layer masterbatch into the two extruders (A, B) of the multi-layer extrusion system respectively (see figure 1 ), adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com