Precise dephosphorization nanomaterial and preparation method thereof and conventional power integrated sewage treatment equipment

A technology of sewage treatment equipment and nanomaterials, applied in the field of water treatment, can solve problems such as low removal efficiency and heavy metal pollution, and achieve the effects of eliminating the risk of point source eutrophication, high mechanical strength, and long sludge discharge cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

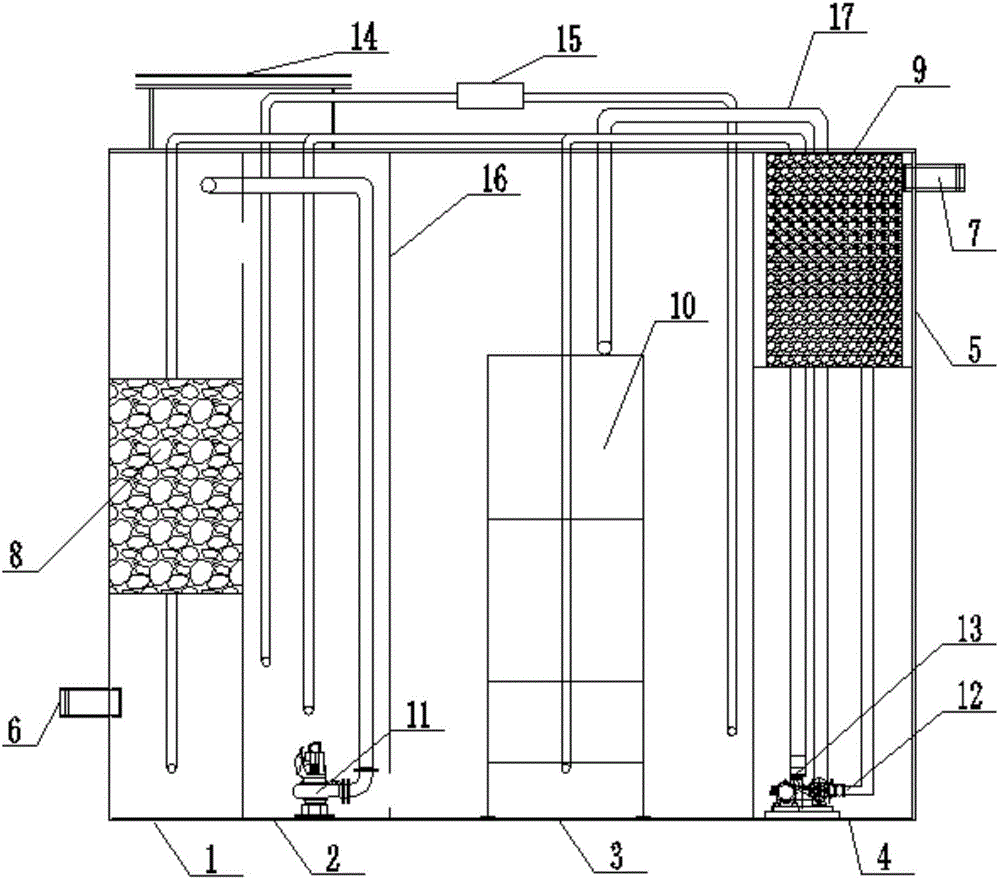

Image

Examples

Embodiment 1

[0061] 1) 35 parts of montmorillonite, 45 parts of bentonite and 20 parts of activated clay are put into a high-speed mixer and mixed to obtain a dry blend, wherein the fineness of montmorillonite is below 5 microns and the purity is 98 % or more; the fineness of bentonite is below 10 microns, and the purity is above 95%; the fineness of activated clay is below 8 microns, and the purity is above 95%;

[0062] 2) Wet mix 20% calcium acetate solution with the dry mixture obtained in step 1) according to the mass ratio of 0.3:1, and then mud mix after wet mixing, and the mud mixing time is 25 minutes to obtain mud block;

[0063] 3) extrude the mud block obtained in step 2) into granules, and the particle diameter of the granules is 8 millimeters;

[0064] 4) drying the particles obtained in step 3) in a drying kiln to obtain a dry molded product with a moisture content lower than 8%;

[0065] 5) The dried molded product obtained in step 4) is heated up to a firing temperature o...

Embodiment 2

[0067] 1) Put 20 parts of montmorillonite, 60 parts of bentonite and 10 parts of activated clay into a high-speed mixer and mix to obtain a dry blend, wherein the fineness of montmorillonite is below 5 microns and the purity is 98 % or more; the fineness of bentonite is below 10 microns, and the purity is above 95%; the fineness of activated clay is below 8 microns, and the purity is above 95%;

[0068] 2) 22% calcium acetate solution and the dry mixture obtained in step 1) were wet-mixed according to a mass ratio of 0.2:1, and after the wet-mixing, the mud was mixed for 30 minutes to obtain mud blocks;

[0069] 3) Extrude the mud block obtained in step 2) into granules, and the particle diameter of the granules is 3 millimeters;

[0070] 4) drying the particles obtained in step 3) in a drying kiln to obtain a dry molded product with a moisture content lower than 8%;

[0071] 5) The dried molded product obtained in step 4) is heated to a firing temperature of 700° C. for 1.5 ...

Embodiment 3

[0073] 1) Put 50 parts of montmorillonite, 30 parts of bentonite and 30 parts of activated clay into a high-speed mixer and mix to obtain a dry mixture, wherein the fineness of montmorillonite is below 5 microns and the purity is 98 % or more; the fineness of bentonite is below 10 microns, and the purity is above 95%; the fineness of activated clay is below 8 microns, and the purity is above 95%;

[0074] 2) Wet mix 18% calcium acetate solution with the dry mixture obtained in step 1) according to the mass ratio of 0.4:1, and then mud mix after wet mixing for 20 minutes to obtain mud block;

[0075] 3) extrude the mud block obtained in step 2) into granules, and the particle diameter of the granules is 12 millimeters;

[0076] 4) drying the particles obtained in step 3) in a drying kiln to obtain a dry molded product with a moisture content lower than 8%;

[0077] 5) The dried molded product obtained in step 4) is heated to a firing temperature of 700° C. for 1.5 hours and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com