Preparation method and application of zero-valent nano-iron supported polyacrylonitrile membrane composite material

A technology of polyacrylonitrile membrane and composite materials, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of membrane structure damage, polyacrylonitrile membrane stability and strength reduction and other problems, to achieve low cost, improve recovery rate, and solve the effect of easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

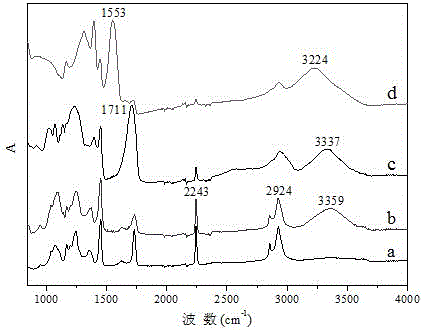

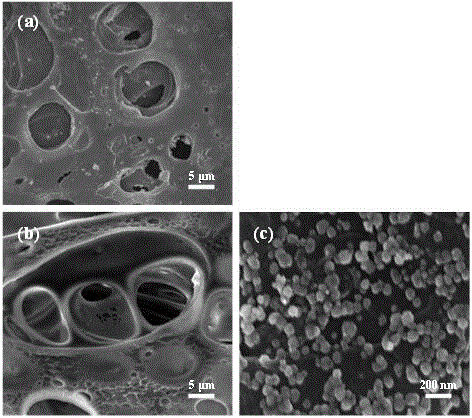

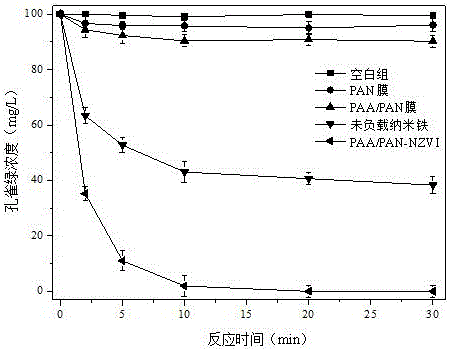

[0032] Example 1: Preparation method of zero-valent nano-iron-based polyacrylonitrile (PAN) membrane composite material, analysis of surface chemical structure and morphological characteristics, and removal effect of malachite green dye in water. The specific content is as follows:

[0033] (1) The polyethylene glycol powder was first completely dissolved in dimethyl sulfoxide solvent at room temperature, then polyacrylonitrile and polyvinyl alcohol powder were added in sequence, and stirred in a water bath at 65°C for 26 h to obtain a homogeneous hydrophilization Polyacrylonitrile solution (the mass percent concentration of the composition in dimethyl sulfoxide is 9.6% polyacrylonitrile, 3.5% polyvinyl alcohol, and 5.0% polyethylene glycol). Cool at room temperature and let it stand for 6 hours to remove the solution bubbles, transfer the casting solution to one end of a clean glass plate, and pull the scraper to the other end of the glass plate at a uniform speed to scrape ou...

Embodiment 2

[0042] Embodiment 2: the preparation method and negative iron amount research of the composite material of loading zero-valent nano-iron-based polyacrylonitrile membrane and the removal effect of antibiotic metronidazole, the specific contents are as follows:

[0043] (1) Polyethylene glycol powder was completely dissolved in dimethyl sulfoxide solvent at room temperature, polyacrylonitrile and polyvinyl alcohol powder were added in sequence, and stirred at 50 °C for 24 h to obtain a homogeneous hydrophilized polyacrylonitrile solution (composition The mass percent concentrations of the substances in dimethyl sulfoxide were 8.0% for polyacrylonitrile, 2.1% for polyvinyl alcohol, and 3.2% for polyethylene glycol). Cool to room temperature and let it stand for 6 hours to remove the solution bubbles, transfer the casting solution to one end of a clean glass plate, pull the scraper to the other end of the glass plate at a uniform speed, and scrape out a nascent film with uniform th...

Embodiment 3

[0050] Example 3: Preparation method of zero-valent nano-iron-based polyacrylonitrile membrane composite material and its alignment with Cr 6+ The removal effect of heavy metal simulated wastewater is as follows:

[0051] (1) Dissolve polyethylene glycol powder completely in dimethyl sulfoxide solvent at room temperature, then add polyacrylonitrile and polyvinyl alcohol powder in sequence, and stir in a water bath at 60°C for 30 h to prepare homogeneous hydrophilized polypropylene Nitrile solution (the mass percent concentration of the composition in dimethyl sulfoxide is 10.0% polyacrylonitrile, 4.6% polyvinyl alcohol, and 6.5% polyethylene glycol). Cool at room temperature and let it stand for 8 hours to remove the solution bubbles, transfer the casting solution to one end of a clean glass plate, and pull the scraper to the other end of the glass plate at a uniform speed to scrape out a nascent film with uniform thickness. Stand in the air for 30 s, quickly immerse in a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com