Preparation method and application of visible-light responsive g-C3N4/Bi2S3 heterojunction material

A visible light and heterojunction technology, applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as easy agglomeration, high electron load rate, limitations, etc., and achieve the preparation process Simple, long life, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

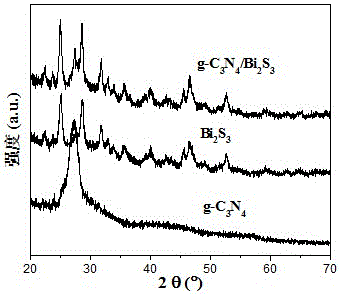

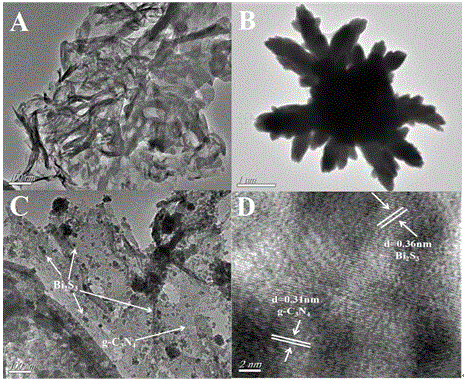

[0025] Prepare g-C 3 N 4 / Bi 2 S 3 Heterojunction Materials:

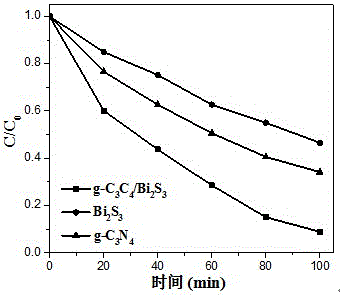

[0026] Add 0.16g of carbon nitride into 15mL of deionized water, stir and ultrasonically disperse for 1 hour, then add 0.242g of bismuth nitrate hexahydrate, stir evenly, then add 0.18g of L-cysteine, ultrasonically disperse for 5min, and dissolve the reactant After mixing evenly, transfer the reaction solution into a 50mL stainless steel autoclave, heat it at a constant temperature of 140°C, react for 24h, cool it down to room temperature naturally, wash it with deionized water and absolute ethanol three times respectively, and dry it under vacuum at 60°C for 10h. get the g-C 3 N 4 / Bi 2 S 3 heterojunction materials. The material can degrade 93% of Rhodamine B in 100 minutes under visible light irradiation.

[0027] Preparation of monomeric Bi 2 S 3 :

[0028] Add 0.242g of bismuth nitrate hexahydrate into 20mL of deionized water, stir evenly, then add 0.18g of L-cysteine, ultrasonically disperse for 5...

Embodiment 2

[0033] Add 0.24g of carbon nitride into 20mL of deionized water, and ultrasonically disperse for 1 hour after stirring, then add 0.48g of bismuth nitrate hexahydrate, stir evenly, then add 0.25g of L-cysteine, and ultrasonically disperse for 5min. After mixing evenly, transfer the reaction solution into a 50mL stainless steel autoclave, heat it at a constant temperature of 130°C, react for 12h, and cool it down to room temperature naturally, wash it with deionized water and absolute ethanol three times respectively, and dry it under vacuum at 60°C for 6h, namely get the g-C 3 N 4 / Bi 2 S 3 heterojunction materials. The material can degrade 80% of rhodamine B in 100min under visible light irradiation.

Embodiment 3

[0035] Add 0.10g of carbon nitride into 20mL of deionized water, stir and ultrasonically disperse for 0.5h, then add 0.20g of bismuth nitrate hexahydrate, stir evenly, then add 0.14g of L-cysteine, ultrasonically disperse for 3min, and the reaction After the mixture was evenly mixed, the reaction solution was transferred into a 50mL stainless steel autoclave, heated at a constant temperature of 120°C, reacted for 24 hours, cooled to room temperature naturally, washed with deionized water and absolute ethanol three times respectively, and dried under vacuum at 60°C for 6 hours. That is, get the g-C 3 N 4 / Bi 2 S 3 heterojunction materials. The material can degrade 86% of rhodamine B in 100min under visible light irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com