A kind of electrochemical enrichment culture method of anammox biofilm

An anammox and bioelectrochemical technology, which is applied in the field of electrochemical enrichment culture of anammox biofilms, can solve the problems of long start-up time, difficult cultivation, slow growth of anammox bacteria, etc. Fast time, stable anammox biofilm, good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The electrochemical enrichment culture method of embodiment 1 anammox biofilm

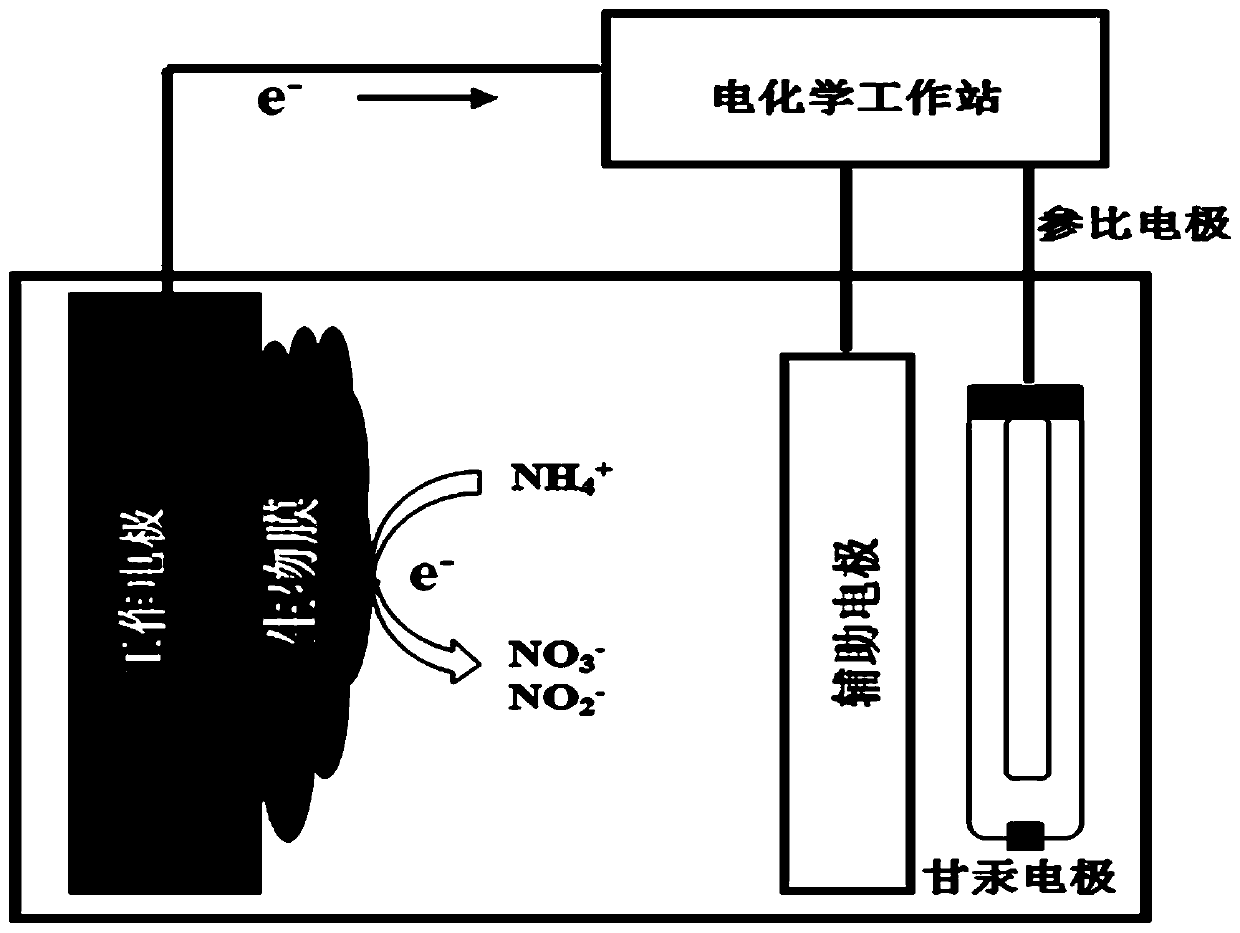

[0043] (1) Construction of bioelectrochemical reactor

[0044] The shell of the bioelectrochemical reactor is cuboid plexiglass, and the interior is a cylindrical structure with a length of 6cm and a diameter of 3cm. The working electrode is a carbon brush with a length of 3cm and a diameter of 3cm, and the auxiliary electrode is a carbon cloth with a diameter of 3cm. The bioelectrochemical reactor and The CHI1040c multi-channel electrochemical workstation of Shanghai Chenhua Company is connected, and the anode potential is set to 0V (the reference electrode is a saturated calomel electrode). The working schematic diagram of the bioelectrochemical reactor is as follows figure 1 shown.

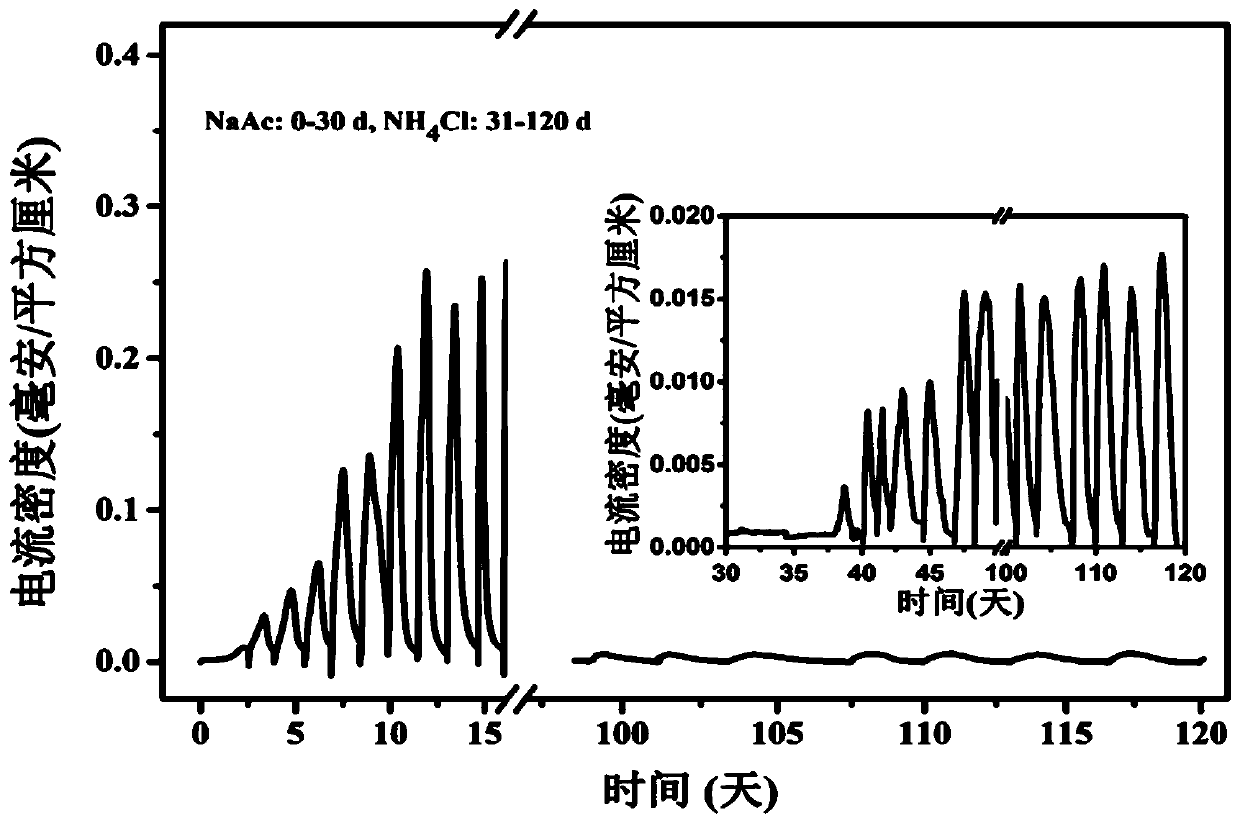

[0045](2) Electrochemical enrichment culture of anammox biofilm

[0046] In the bioelectrochemical reactor, the inoculation amount of anaerobic activated sludge is 10% of the working volume, adding acetic a...

Embodiment 2

[0056] Example 2 Effect of anaerobic ammonium oxidation biofilm on ammonia nitrogen degradation

[0057] The anammox biofilm successfully enriched in Example 1 was inoculated in the ammonium chloride matrix culture solution containing 5 mM ammonium chloride, cultured at 30°C for 50 h, and tested for 0, 8, 18, 30, and 50 h, respectively. The content of nitrate nitrogen, nitrite nitrogen and ammonia nitrogen.

[0058] The result is as Figure 5 As shown, within 8 hours, the anaerobic ammonium oxidation reached 46% ± 2%; within 50 hours, 5mM ammonia nitrogen could be degraded by 80%, and the concentrations of nitrite and nitrate in the corresponding products were both low. It shows that the ammonia nitrogen in the matrix can be effectively oxidized by the anammox biofilm to gas products such as nitrogen or nitrogen oxides, so that the ammonia nitrogen can be removed from the sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com