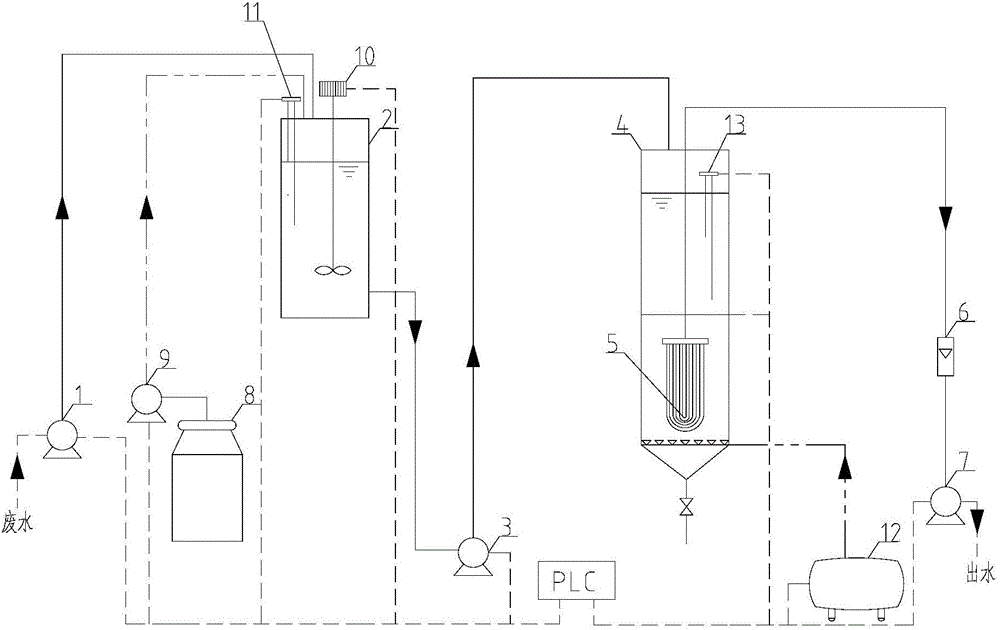

Copper-containing wastewater treatment method and device

A waste water and pretreatment technology, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor copper removal effect, low sodium carbonate dosage, and unreachable effluent and other problems, to achieve the effect of increasing the sludge concentration ratio, increasing the concentration ratio, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the treatment water capacity of device is 15L / h, and the residence time of mechanical stirring reactor is 15 minutes (stirring 5 minutes, precipitation 10 minutes), and the hydraulic retention time of membrane separator is 30 minutes. The device is used to treat simulated wastewater with a pH value of 6.1-6.2 and a copper concentration of 20 mg / L. At the start of the experiment, 0.5g / L basic copper carbonate seed crystals were added to the mechanically stirred reactor; in the experiment, when the dosage of sodium carbonate was controlled at 104mg / L, the mass concentration of copper in the effluent was stabilized below 1mg / L, and with The increase in the amount of treated water gradually decreased to 0.4mg / L, and the removal efficiency reached 98%; the concentration of carbonate ions in the effluent was 50-55mg / L. Under this condition, the concentration factor of the process is 7982. Membrane specific flux from the initial 57L / (m 2 h m) to 33L / (m 2 h m),...

Embodiment 2

[0027] Embodiment 2: the treatment water volume of device is 15L / h, and the residence time of mechanical stirring reactor is 15 minutes (stirring 5 minutes, precipitation 10 minutes), and the hydraulic residence time of membrane separator is 45 minutes. The device is used to treat simulated wastewater with a pH value of 6.2-6.4 and a copper concentration of 20 mg / L. At the start of the experiment, 0.5g / L basic copper carbonate seed crystals were added to the mechanically stirred reactor; in the experiment, when the dosage of sodium carbonate was controlled at 104mg / L, the concentration of copper in the effluent was stabilized below 2mg / L, and the amount of treated water reached After 800L, the concentration of copper in the effluent is stable at 0.07mg / L, and the removal rate reaches 99%; the concentration of carbonate ions in the effluent is 50-55mg / L. Under this condition, the concentration factor of the process is 3175. Membrane specific flux from the initial 62.2L / (m 2 h...

Embodiment 3

[0028]Embodiment 3: the treatment water volume of device is 20L / h, and the residence time of mechanical stirring reactor is 30 minutes (stirring 5 minutes, precipitation 16 minutes), and the hydraulic residence time of membrane separator is 30 minutes. The device is used to treat simulated wastewater with a pH value of 6.1-6.2 and a copper concentration of 50 mg / L. At the start of the experiment, 1g / L basic copper carbonate seeds were added to the mechanically stirred reactor; in the experiment, when the dosage of sodium carbonate was controlled at 180mg / L, the concentration of copper in the effluent was stable at about 0.5mg / L, and the removal rate reached 99%; the carbonate ion concentration in the effluent is 50-60mg / L. Membrane specific flux from the initial 46.9L / (m 2 ·h·m) to 29.6L / (m 2 h m), it can be recovered to 46.2L / (m after chemical cleaning 2 h m).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com