Production method of multifunctional quincunx bagasse lightweight through-hole ceramisite

A light-weight through-hole ceramsite and production method technology, applied in the production of ceramic materials, ceramic products, applications, etc., can solve the problems of high bulk density, low water absorption, small specific surface area, etc., to increase porosity and save energy , to ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with embodiment the present invention will be further described:

[0069] 1. The production method of multifunctional plum-shaped bagasse lightweight through-hole ceramsite:

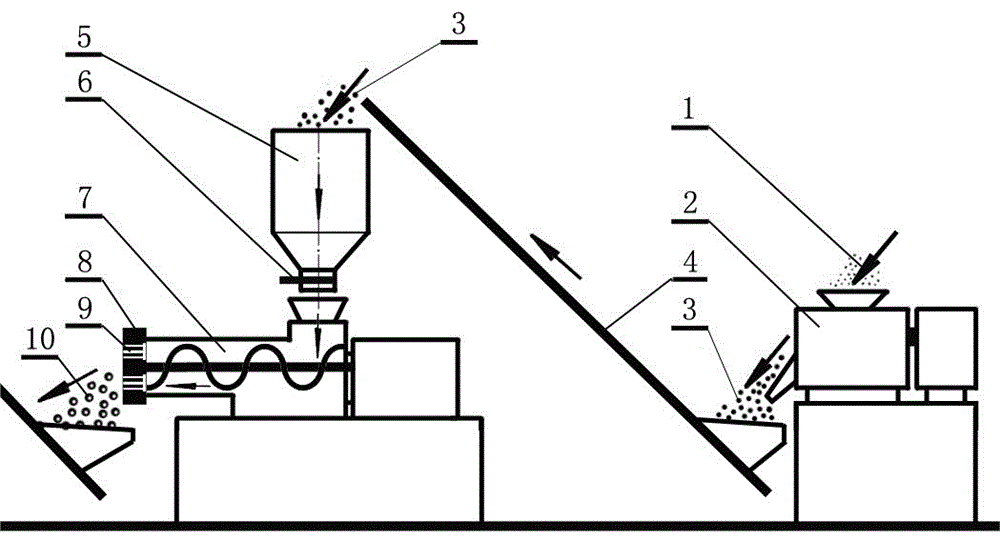

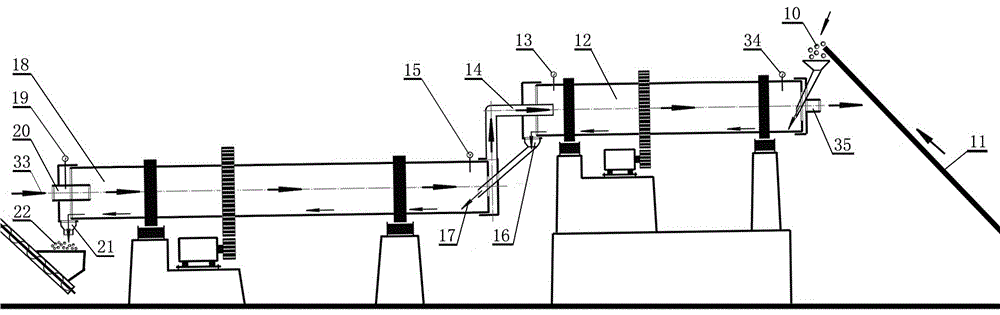

[0070] (1) Input the ingredients 1 of the multi-functional plum-shaped bagasse lightweight through-hole ceramsite semi-finished product into the already running mixing mixer 2, stir and mix it into a mixture 3 of the multi-functional plum-shaped bagasse light-weight through-hole ceramsite semi-finished product, and pass through the belt The machine 4 is delivered to the feed bin 5 on the top of the screw extruder granulator 7 for subsequent use;

[0071] (2) Place the mold core 9 used to produce the semi-finished product of multi-functional plum-shaped bagasse lightweight through-hole ceramsite in the template 8 of the screw extrusion granulator 7, open the valve 6 of the feed bin 5, and place the multi-functional plum-shaped The mixture 3 of bagasse light through-hole cerams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com