Methyl formate-methanol-liquid mixture separation energy saving method

A technology of methyl formate and mixture is applied in the field of energy saving of methanol and water mixture and separation of methyl formate to achieve the effects of low equipment cost, convenient operation and improved energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

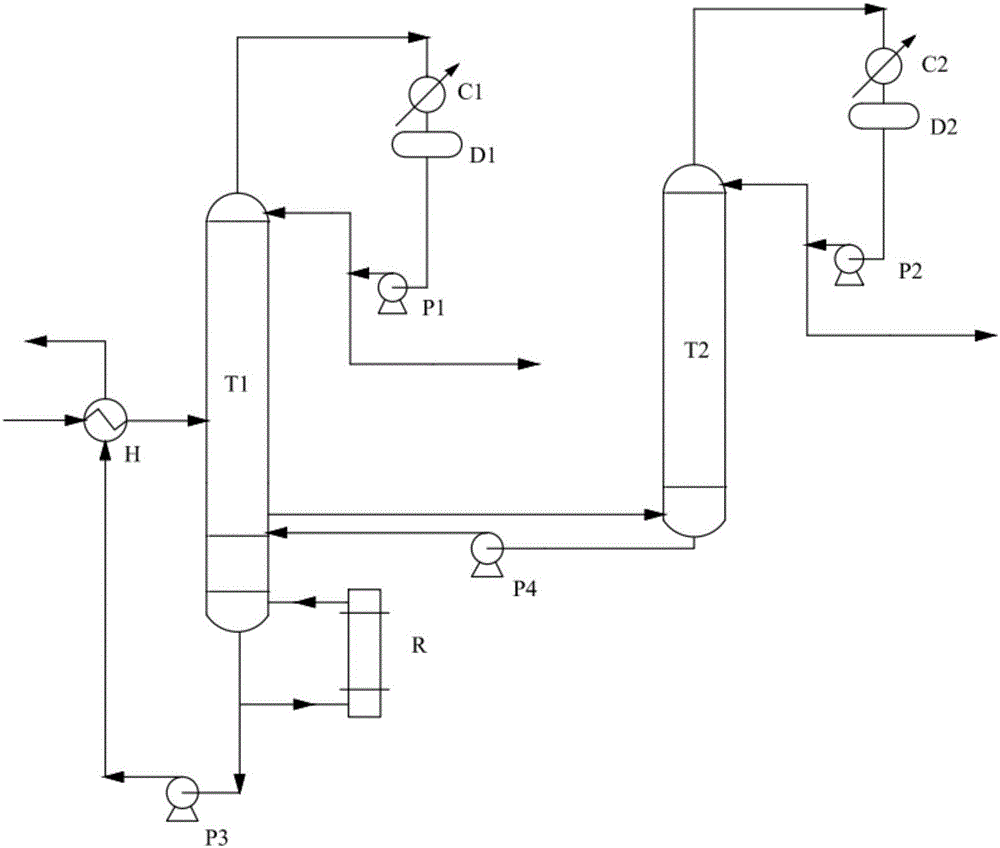

Embodiment 1

[0035] Feed temperature is 30 ℃, flow rate is 1000kg / h, pressure is 1atm absolute pressure, the mass fraction of methyl formate in the feed is 10%, the mass fraction of methyl alcohol is 40%, and the mass fraction of water is 50%. The theoretical plate number of the main rectifying column is 40, the feeding plate of the methyl formate-methanol-water mixture is 20, and the theoretical plate number of the auxiliary rectifying column is 15; the operating pressure of the main rectifying column is 1 atm absolute pressure, and the reflux ratio is 1, The temperature at the top of the tower is 34.3°C, the temperature at the bottom of the tower is 100.9°C, the operating pressure of the sub-distillation column is 0.8atm absolute pressure, the reflux ratio is 0.9, the temperature at the top of the tower is 59.2°C, the quality of the steam and feed entering the sub-distillation column The ratio is 0.5. The mass fraction of methyl formate after separation is 99.00%, the mass fraction of me...

Embodiment 2

[0039] Feed temperature is 30 ℃, flow rate is 1000kg / h, pressure is 1atm absolute pressure, the mass fraction of methyl formate in the feed is 30%, the mass fraction of methyl alcohol is 30%, and the mass fraction of water is 40%. The theoretical plate number of the main rectifying column is 50, the feeding plate of the methyl formate-methanol-water mixture is 25, and the theoretical plate number of the auxiliary rectifying column is 25; the operating pressure of the main rectifying column is 1 atm absolute pressure, and the reflux ratio is 2, The temperature at the top of the tower is 32.1°C, the temperature at the bottom of the tower is 100.4°C, the operating pressure of the sub-distillation tower is 0.7atm absolute pressure, the reflux ratio is 1.4, the temperature at the top of the tower is 56°C, the quality of the steam and feed entering the sub-distillation tower The ratio is 0.4. The mass fraction of methyl formate after separation is 99.50%, the mass fraction of methan...

Embodiment 3

[0043] Feed temperature is 30 ℃, flow rate is 1000kg / h, pressure is 1atm absolute pressure, the mass fraction of methyl formate in the feed is 50%, the mass fraction of methyl alcohol is 40%, and the mass fraction of water is 10%. The theoretical plate number of the main rectifying column is 60, the feeding plate of the methyl formate-methanol-water mixture is 30, and the theoretical plate number of the auxiliary rectifying column is 25; the operating pressure of the main rectifying column is 1 atm absolute pressure, and the reflux ratio is 3, The temperature at the top of the tower is 31.9°C, the temperature at the bottom of the tower is 100°C, the operating pressure of the sub-distillation column is 0.6atm absolute pressure, the reflux ratio is 2, the temperature at the top of the tower is 52.4°C, the quality of the steam and feed entering the sub-distillation column The ratio is 0.6. The mass fraction of methyl formate after separation is 99.35%, the mass fraction of methan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com