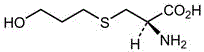

Preparation method of fudosteine crystals

A fodosteine and crystallization technology, which is applied in the field of preparation of fodosteine crystallization, can solve the problems of uneven particle size distribution, high dissolution temperature, and the product is not easy to dry, and achieves the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

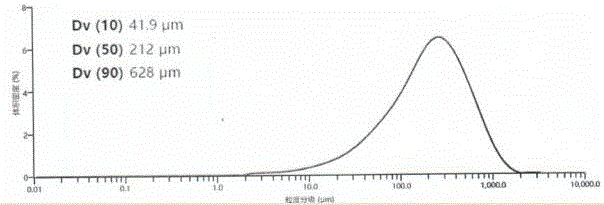

[0024] Add 50 g of fudosteine into a three-necked flask filled with 100 ml of water, stir and dissolve at 40°C, and then filter and decolorize after stirring continuously for 30 minutes; Cool the filtrate to 10°C, add 0.25g seed crystals to the crystallizer, and grow the crystals for 2 hours, then add 400ml of n-propanol to the crystallizer at a flow rate of 10ml / min, and then grow the crystals for 3 hours; Suction filter, wash the filter cake with n-propanol, and dry under normal pressure at 40°C for 12 hours. The final product yield is 88.7%, and the HPLC purity is 99.93%, and the crystal habit of the product is flake (such as figure 1 shown), with a primary particle size of 212 microns (as figure 2 shown).

Embodiment 2

[0026] Add 30 g of fudosteine into a three-necked flask filled with 30 ml of water, stir and dissolve at 50°C, and then filter and decolorize after stirring continuously for 60 minutes; Cool the filtrate to 20°C, add 0.3g seed crystals to the crystallizer, and grow the crystals for 1 hour, then add 300ml of n-propanol to the crystallizer at a rate of 2 ml / min, and then grow the crystals for 1 hour ; Suction filtration, and the filter cake was washed with n-propanol, and dried under normal pressure at 45°C for 10 hours. The yield of the final product is 90.2%, the HPLC purity is 99.91%, the crystal habit of the product is flaky, and the main particle size is 189 microns.

Embodiment 3

[0028] Add 40 g of fudosteine into a three-necked flask filled with 50 ml of water, stir and dissolve at 45°C, and then filter and decolorize after stirring continuously for 50 minutes; Cool the filtrate to 15°C, add 0.28g seed crystals to the crystallizer, and grow the crystals for 1.5 hours, then add 400ml of isopropanol to the crystallizer at a flow rate of 5 ml / min, and then grow the crystals for 2 hours ; Suction filtration, and wash the filter cake with isopropanol, and dry under normal pressure at 50°C for 8 hours. The final product yield is 90.2%, and the HPLC purity is 99.91%. The crystal habit of the product is flaky, and the main particle size is 215 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com