Method for extracting salidroside from rhodiola

A technology of salidroside and rhodiola rosea, which is applied in the field of salidroside extraction, can solve problems such as unstable product quality, long processing time, and sharp decrease in membrane flux, so as to improve the use value and scope of use, shorten the Extraction time, the effect of reducing the difficulty of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

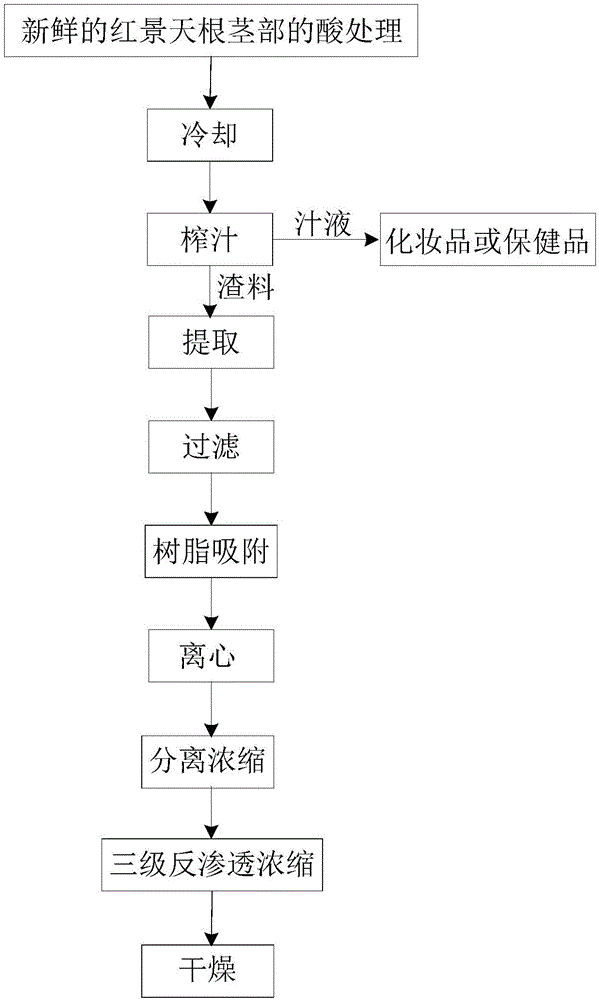

Image

Examples

Embodiment 1

[0041] 1. Put the rhizome of 2 kg of fresh Rhodiola rosea into 0.2% hydrochloric acid and soak for 10 minutes, and wash the soaked raw materials until the residual acid content is not more than 0.4g / L, and wash the fresh Rhodiola rosea after washing. The rhizome of Rhodiola rosea is cooled to 8°C, and the cooled fresh rhizome of Rhodiola rosea is squeezed with a screw juicer, and the squeezed juice is sequentially used with a 0.5 μm microfiltration membrane and a 0.01 μm ultrafiltration membrane Filtration is carried out, and the filter residue obtained by filtration is combined with the residue obtained by pressing to obtain residue material.

[0042] Two, adopt the method that ethanol leaching and ultrasonic extraction combine to extract described slag material, obtain extracting liquid:

[0043] Ethanol leaching includes two steps of primary leaching and secondary leaching in turn: put the slag into the extraction tank, add 70% ethanol of the first mass to the extraction ta...

Embodiment 2

[0053] 1. Put the rhizome of 2 kg of fresh Rhodiola rosea into 0.2% hydrochloric acid and soak for 10 minutes, and wash the soaked raw materials until the residual acid content is not more than 0.4g / L, and wash the fresh Rhodiola rosea after washing. The rhizome of Rhodiola rosea is cooled to 12°C, and the cooled fresh rhizome of Rhodiola rosea is squeezed with a screw juice extractor, and the squeezed juice is sequentially used with a 0.3 μm microfiltration membrane and a 0.005 μm ultrafiltration membrane Filtration is carried out, and the filter residue obtained by filtration is combined with the residue obtained by pressing to obtain residue material.

[0054] Two, adopt the method that ethanol leaching and ultrasonic extraction combine to extract described slag material, obtain extracting solution:

[0055] Ethanol leaching includes two steps of primary leaching and secondary leaching in turn: put the slag into the extraction tank, add the first mass of 70% ethanol to the ...

Embodiment 3

[0065] 1. Put the rhizome of 2 kg of fresh Rhodiola rosea into 0.2% hydrochloric acid and soak for 10 minutes, and wash the soaked raw materials until the residual acid content is not more than 0.4g / L, and wash the fresh Rhodiola rosea after washing. The rhizome of Rhodiola rosea is cooled to 8°C, and the cooled fresh rhizome of Rhodiola rosea is squeezed with a screw juice extractor, and the squeezed juice is sequentially used with a 0.1 μm microfiltration membrane and a 0.005 μm ultrafiltration membrane Filtration is carried out, and the filter residue obtained by filtration is combined with the residue obtained by pressing to obtain residue material.

[0066] Two, adopt the method that ethanol leaching and ultrasonic extraction combine to extract described slag material, obtain extracting liquid:

[0067] Ethanol leaching includes two steps of primary leaching and secondary leaching in turn: put the slag into the extraction tank, add 70% ethanol of the first mass to the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com