Glass chip packaging method

A glass chip and packaging method technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid devices, etc., can solve the problems of conductive leads and glass damage, limited packaging thickness, poor packaging performance, etc., and achieve excellent sealing performance and long service life The effect of unlimited length and chip thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

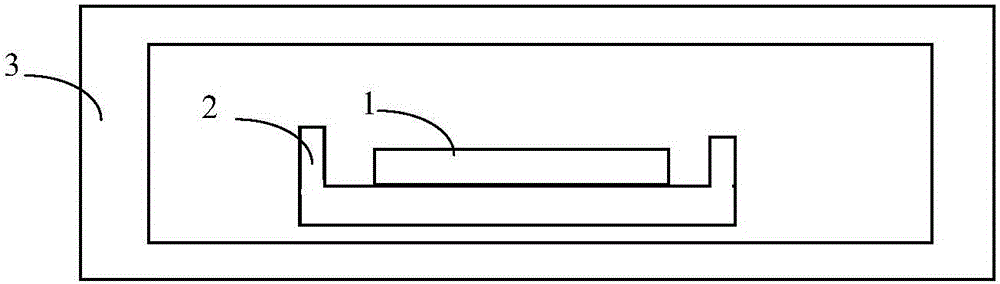

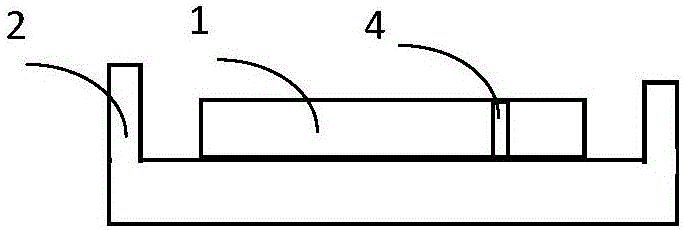

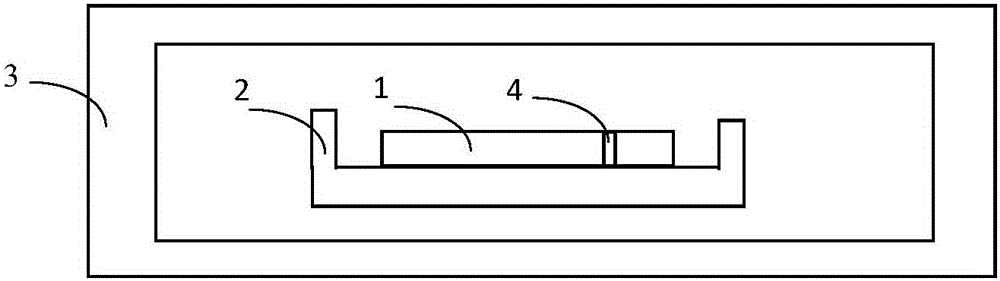

[0059] Example 1: Fabrication of glass perovskite solar cell chip packaging

[0060] Put the crucible mold with the first flat glass substrate with a thickness of 1mm, length and width of 20mm and 15mm respectively into a high-temperature heating furnace, raise the temperature evenly to 550°C to soften the first flat glass substrate, and take out the crucible mold . Quickly insert two copper wires with a diameter of 1 mm into the first flat glass substrate to soften, allowing the copper wires to penetrate through the glass sheet to soften. Then put the crucible mold into a high-temperature heating furnace, raise the temperature to 700°C, and stay for 3 minutes, so that the glass sheet and the copper wire are fully and closely contacted to achieve the sealing condition. After slowly lowering the high-temperature heating furnace to room temperature, a penetrating conductive metal electrode penetrating through its thickness and having good sealing properties is obtained on the f...

example 2

[0061]Example 2: Encapsulation of glass biochips

[0062] Put the crucible mold with the first flat glass substrate with a thickness of 1mm, length and width of 20mm and 15mm respectively into a high-temperature heating furnace, raise the temperature evenly to 550°C to soften the first flat glass substrate, and take out the crucible mold . Quickly insert two copper wires with a diameter of 1 mm into the first flat glass substrate to soften, allowing the copper wires to penetrate through the glass sheet to soften. Then put the crucible mold into a high-temperature heating furnace, raise the temperature to 700°C, and stay for 3 minutes, so that the glass sheet and the copper wire are fully and closely contacted to achieve the sealing condition. After the temperature is slowly lowered to room temperature, a penetrating conductive metal electrode penetrating through its thickness and having good sealing performance is obtained on the first flat glass substrate. Prepare a biochip...

example 3

[0063] Example 3: Fabrication of Glass Organic Light Emitting Diode (OLED) Chip Packaging

[0064] Put the crucible mold with the first flat glass substrate with a thickness of 1mm, length and width of 10mm and 8mm respectively into a high-temperature heating furnace, and raise the temperature evenly to 500°C to soften the first flat glass substrate, and take out the crucible mold . Quickly insert two copper wires with a diameter of 2 mm into the first flat glass substrate to soften, allowing the copper wires to penetrate through the glass sheet to soften. Then put the crucible mold into a high-temperature heating furnace, raise the temperature to 700°C, and stay for 3 minutes, so that the glass sheet and the copper wire are fully and closely contacted to achieve the sealing condition. After the temperature is slowly lowered to room temperature, a penetrating conductive metal electrode penetrating through its thickness and having good sealing performance is obtained on the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com