A kind of composite nanomaterial for lithium ion battery and preparation method thereof

A composite nanomaterial, lithium-ion battery technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problems of unsatisfactory charge and discharge performance, limited electron transfer speed and electrical conductivity. , to achieve the effect of improving anti-overcharge performance, good stable cycle performance and increasing discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

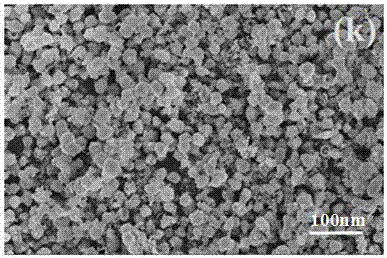

Image

Examples

Embodiment 1

[0024] A preparation method for a lithium-ion battery composite nanomaterial, comprising the steps of:

[0025] (1) Add 5g of tetraethyl orthosilicate to 30mL of ethanol and stir to dissolve, then add 0.5g of polyethylene glycol 2000 and ultrasonically disperse for 15min, then add 10mL of urea solution and stir at about 30°C for 1h to form a sol for later use;

[0026] (2) Take 5g vanadium oxide V0 2 Add it into 20mL hydrogen peroxide solution with a mass fraction of 5%, stir until all the vanadium oxides are dissolved to form a red peroxovanadic acid solution, continue to stir at room temperature for 1 hour and set aside;

[0027] (3) Dissolve the carbon source glucose and ferrocene in acetone to form a uniform and stable solution for later use. The amount of the carbon source added is 15g / L, and the concentration of ferrocene is 0.002mol / L; then the formed The solution is added into the reaction kettle for heat treatment, the heat treatment conditions are: temperature 180°C...

Embodiment 2

[0030] A preparation method for a lithium-ion battery composite nanomaterial, comprising the steps of:

[0031] (1) Add 10g of tetraethyl orthosilicate to 40mL of ethanol and stir to dissolve, then add 1g of polyethylene glycol 2000 and ultrasonically disperse for 15min, then add 15mL of urea solution and stir at about 30°C for 2h to form a sol for later use;

[0032] (2) Take 10g of vanadium oxide V 2 0 3 Add it into 25mL of hydrogen peroxide solution with a mass fraction of 15%, stir until all the vanadium oxides are dissolved to form a red peroxovanadic acid solution, continue to stir at room temperature for 6 h before use;

[0033](3) Dissolve the carbon source sucrose and ferrocene in ethanol to form a uniform and stable solution for later use. The amount of carbon source added is 80g / L, and the concentration of ferrocene is 0.004mol / L; then the formed The solution is added to the reaction kettle for heat treatment, the heat treatment conditions are: temperature 200 ° C...

Embodiment 3

[0036] A preparation method for a lithium-ion battery composite nanomaterial, comprising the steps of:

[0037] (1) Add 8g tetraethyl orthosilicate to 35mL ethanol and stir to dissolve, then add 0.8g polyethylene glycol 2000 and ultrasonically disperse for 15min, then add 12mL urea solution and stir at 30°C for 1.5h to form a sol for later use ;

[0038] (2) Take 8g of vanadium oxide V 2 0 5 Add it into 22mL of hydrogen peroxide solution with a mass fraction of 10%, stir until all the vanadium oxides are dissolved to form a red peroxovanadic acid solution, continue to stir at room temperature for 4 h before use;

[0039] (3) Dissolve the carbon source phenolic resin and ferrocene in acetone to form a uniform and stable solution for later use. The amount of carbon source added is 50g / L, and the concentration of ferrocene is 0.003mol / L; then the formed The solution was added into a reaction kettle for heat treatment, the heat treatment conditions were: temperature 190°C, time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com