Method for improving adhesive performance of lithium battery polyvinylidene fluoride by irradiation

A polyvinylidene fluoride, lithium battery technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as unreported, expansion and deformation, not found, etc., to reduce processing procedures and reduce swelling. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of positive electrode sheet for lithium ion battery:

[0029] The positive electrode active material lithium cobalt oxide, lithium nickel cobalt manganese oxide, conductive carbon, and binder PVDF were mixed in the solvent NMP according to the mass ratio of 70:25:3:2, and stirred evenly to obtain the positive electrode slurry. Coat the obtained positive electrode slurry on a 9 μm aluminum foil, dry, and cold press to obtain a compacted density of 1.5 g / cm 3 The pole piece is then cut and welded to obtain the positive pole piece.

[0030] Preparation of lithium ion battery negative electrode sheet:

[0031] Add the negative electrode active material natural graphite, conductive carbon, and binder PVDF (final melting temperature is 160 degrees) into the solvent NMP according to the mass ratio of 96:2:2, and mix well to obtain the negative electrode slurry, and then coat the negative electrode slurry with Coated on both sides of 8μm thick metal copper foil, d...

Embodiment 2

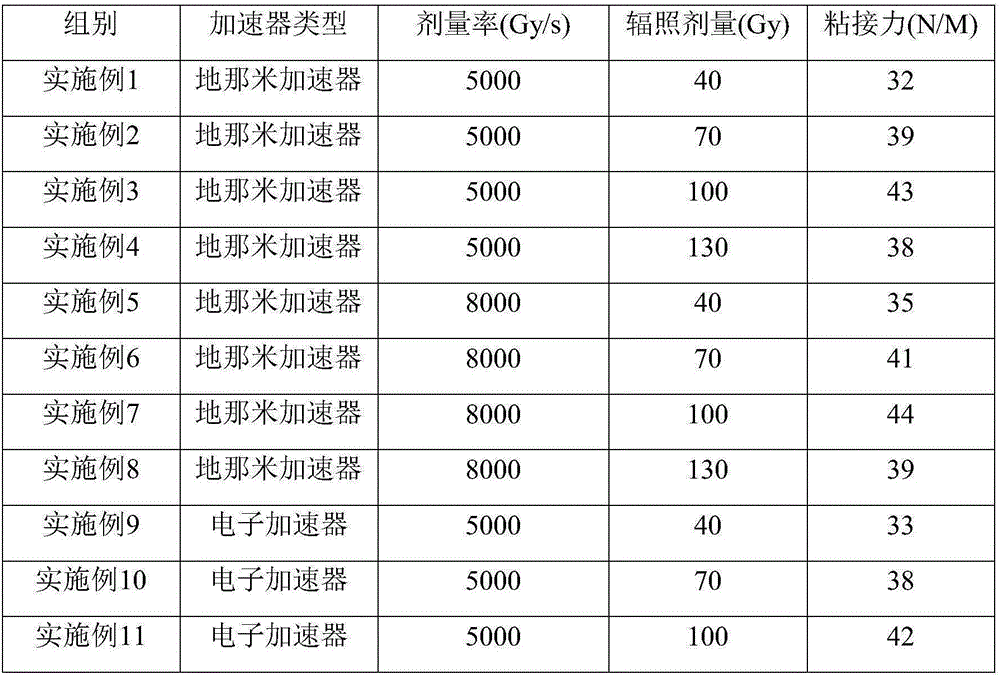

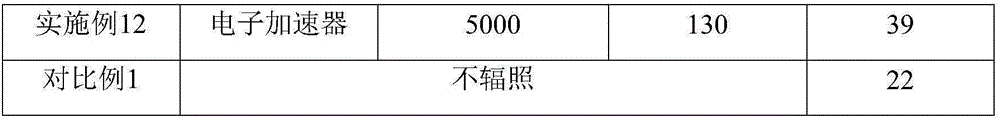

[0040] Different from Example 1 is the irradiation of lithium ion battery:

[0041] Place the lithium-ion battery on the under-beam device under the denami accelerator, load it on a trolley, and lay it out in an orderly manner. Select the denami accelerator, the accelerator energy is 5MeV, adjust the parameters of the irradiation equipment, and adjust the accelerator energy and the speed of the device under the accelerator beam so that the dose rate is 5000Gy / s, and the lithium-ion battery is irradiated. 70kGy, making PVDF partially cross-linked. Afterwards, the lithium-ion battery was taken out of the car, and the battery performance was tested.

[0042] All the other are with embodiment 1.

Embodiment 3

[0044] Different from Example 1 is the irradiation of lithium ion battery:

[0045] Place the lithium-ion battery on the under-beam device under the denami accelerator, load it on a trolley, and lay it out in an orderly manner. Select the denami accelerator, the accelerator energy is 5MeV, adjust the parameters of the irradiation equipment, and adjust the accelerator energy and the speed of the device under the accelerator beam so that the dose rate is 5000Gy / s, and the lithium-ion battery is irradiated. 100 kGy, making PVDF partially cross-linked. Afterwards, the lithium-ion battery was taken out of the car, and the battery performance was tested.

[0046] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com