A self-healing polyanion-chitosan quaternary ammonium hydrogel and its application

A chitosan quaternary ammonium salt and polyanion technology, applied in the field of polymer hydrogels, can solve the problems that the shape cannot be changed at will, unfavorable transplantation, etc., and achieve the effects of low price, abundant material sources, and easy shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Prepare sodium alginate and chitosan quaternary ammonium salt solutions, the concentrations are respectively 20g / L and 40g / L, and the solvent is deionized water. Sodium alginate has a molecular weight of 430kDa and a G fragment content of 35%. The degree of substitution of chitosan quaternary ammonium salt is 85%, and the molecular weight is 78kDa.

[0031] (2) Add the chitosan quaternary ammonium salt solution into an equal volume of sodium alginate solution under shaking conditions, shake and mix well.

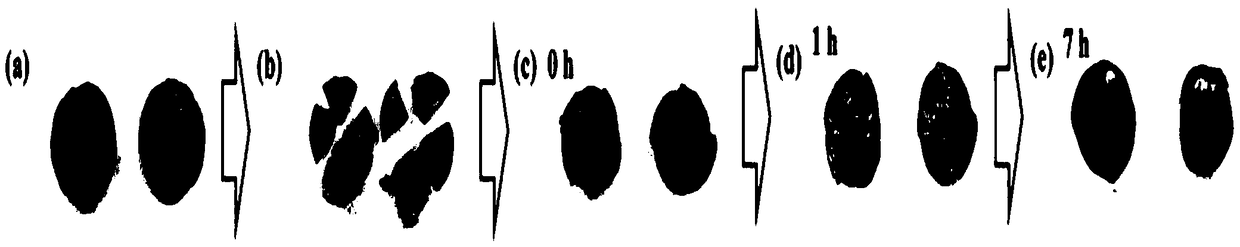

[0032] (3) Static precipitation for 2 hours to collect the product. The formed gels were stained with red basic fuchsin and blue methylene blue respectively, and the two cake-like gels with different colors were evenly divided into 4 parts, and rearranged according to the principle of staggered colors, so that the cut two pieces Gel close up. Thereafter, the gel state was observed at different times. The result is as figure 1 As shown, the boundaries of the t...

Embodiment 2

[0034](1) Prepare carboxymethylcellulose sodium and chitosan quaternary ammonium salt solutions, the mass fraction is 20g / L, and the solvent is deionized water. The molecular weight of sodium carboxymethyl cellulose is 500kDa. The degree of substitution of chitosan quaternary ammonium salt is 85%, and the molecular weight is 78kDa.

[0035] (2) Add the chitosan quaternary ammonium salt solution into an equal volume of sodium alginate solution under shaking conditions, shake and mix well.

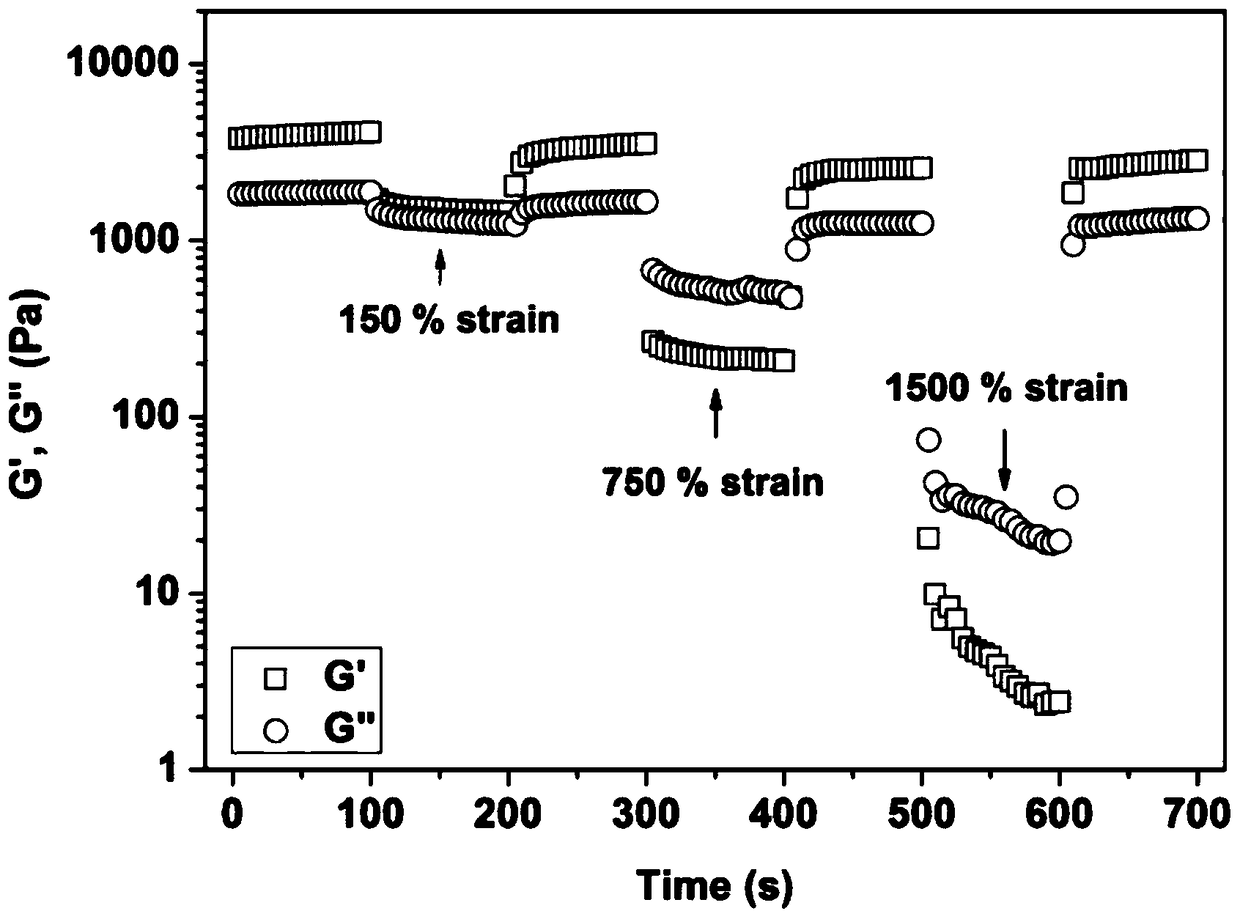

[0036] (3) Static precipitation collected the product for 2 hours, and carried out rheological analysis, such as figure 2 It is shown that by increasing the strain, the structure of the gel is destroyed, and the structure of the gel recovers rapidly after the stress is reduced, and the storage modulus recovers to more than 65% of its original value.

Embodiment 3

[0038] (1) Prepare sodium alginate and chitosan quaternary ammonium salt solutions, the concentrations are respectively 20g / L and 40g / L, and the solvent is deionized water. Sodium alginate has a molecular weight of 430kDa and a G fragment content of 35%. The degree of substitution of chitosan quaternary ammonium salt is 85%, and the molecular weight is 78kDa.

[0039] (2) Add the chitosan quaternary ammonium salt solution into an equal volume of sodium alginate solution under shaking conditions, shake and mix well.

[0040] (3) Static precipitation for 2 hours to collect the product. The formed gel was mixed with water-soluble methylene blue and oil-soluble rhodamine B respectively, and the final drug concentration was 0.1 g / L.

[0041] (4) Collect 1 mL of the gel and place it in 10 mL of phosphate buffer (pH=7.4). At 25°C, the two drugs both exhibit fast and then slow release behavior. The drug release reaches 50% in 24 hours, and the drug is released after 7 days. The con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com