Porous carbon-supported cobalt-based Fischer-Tropsch synthesis catalyst containing silica additive and preparation method thereof

A silica and catalyst technology, applied in the field of highly active cobalt-based Fischer-Tropsch synthesis catalyst and its preparation, can solve the problem of low catalyst activity and liquid product space-time yield, weak cobalt center and carrier force, and unremarkable reaction effect Significant problems, to achieve the effect of easy large-scale synthesis, high number of specific active sites, and complete reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 0.8g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 0.46g terephthalic acid (H 2 BDC) was placed in a 100mL Shrek tube, and a mixed solution formed by adding 20mL DMF and 5mL absolute ethanol was then used to 2 The air in the tube was replaced by gas and sealed well, heated to 110°C for 15h, then filtered while hot, washed three times with 100mL DMF, and finally dried in air at 100°C for 12h to obtain Co-MOF-71 metal organic framework material.

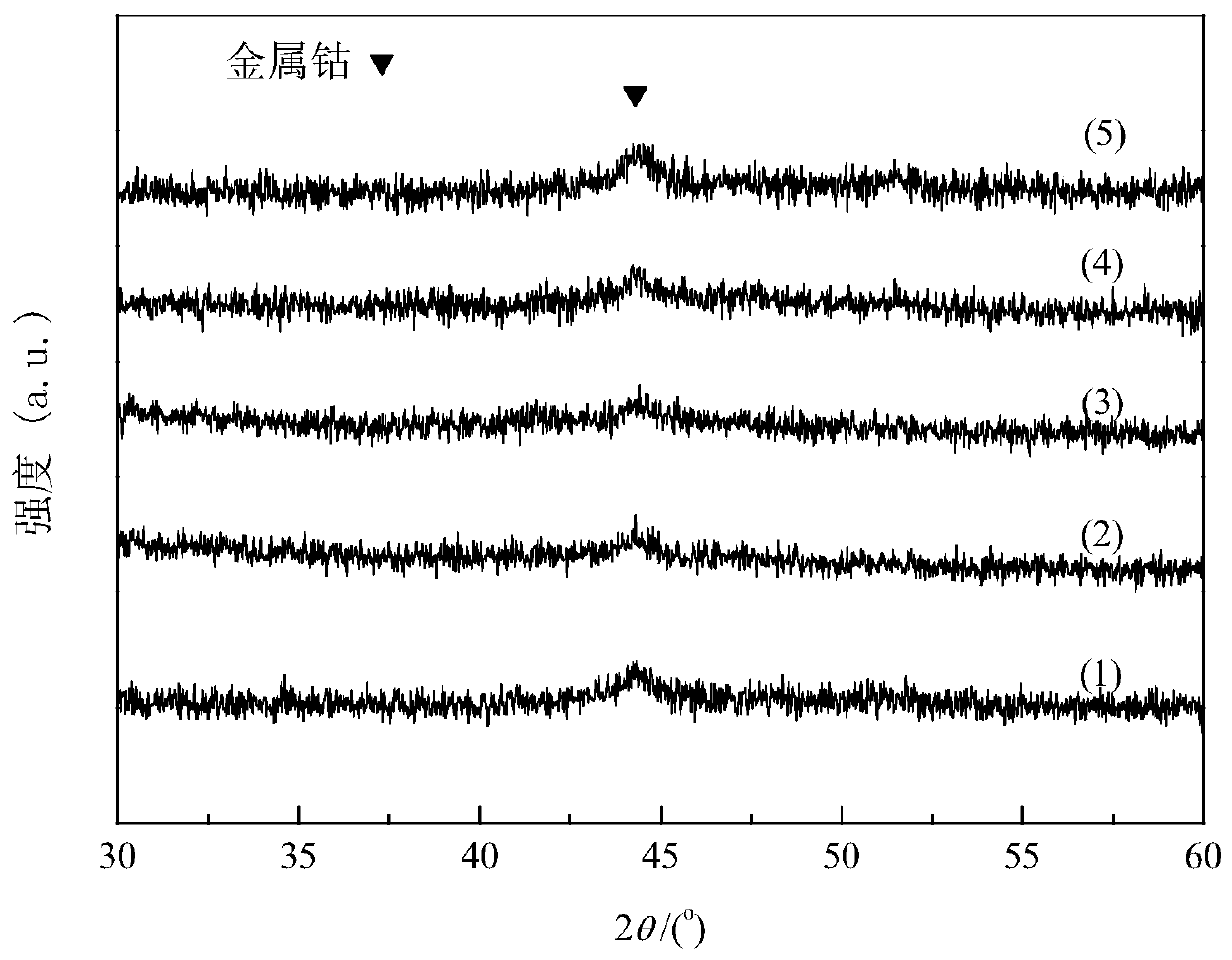

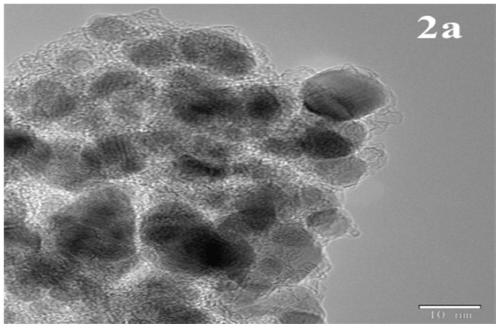

[0038] A porous carbon-supported cobalt catalyst containing silica was prepared according to the following steps, wherein the molar ratio of cobalt to silica was 5:1. Weigh 0.024g of tetraethyl orthosilicate and place it in 1mL of absolute ethanol to form a mixed solution, impregnate the prepared solution on 0.37g of Co-MOF-71 sacrificial template by conventional impregnation method, and then dry it in air at 65°C After 12 hours, the resulting material was diluted with 3 mL of quartz sand and then placed in a fixed-be...

Embodiment 2

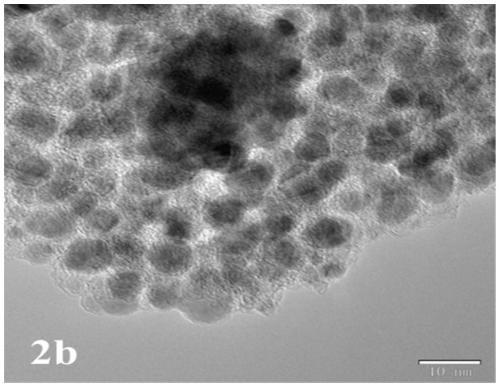

[0042] Using the Co-MOF-71 synthesized in Example 1 as a sacrificial template, a porous carbon-supported cobalt catalyst containing silica was prepared according to the following steps, wherein the molar ratio of cobalt to silica was 5:2. Weigh 0.048g of tetraethyl orthosilicate and place it in 1mL of absolute ethanol to form a mixed solution, impregnate the prepared solution on 0.37g of Co-MOF-71 sacrificial template by conventional impregnation method, and then dry it in air at 65°C After 12 hours, the resulting material was diluted with 3 mL of quartz sand and then placed in a fixed-bed reactor. The temperature was raised to 600 °C at 5 °C / min under He and kept for 8 h, and the molar ratio of cobalt to silicon dioxide was 5:2. Porous carbon-supported cobalt catalyst, the weight of the obtained catalyst is 0.11g, and the volume is about 0.3mL.

[0043] The BET method was used to calculate the specific surface area of the catalyst, and the BJH method was used to calculate t...

Embodiment 3

[0046] Using the synthesized Co-MOF-71 in Example 1 as a sacrificial template, a porous carbon-supported cobalt catalyst containing silica was prepared according to the following steps, wherein the molar ratio of cobalt to silica was 5:3. Weigh 0.072g of tetraethyl orthosilicate and place it in 1mL of absolute ethanol to form a mixed solution, impregnate the prepared solution on 0.37g of Co-MOF-71 sacrificial template by conventional impregnation method, and then dry it in air at 65°C After 12 hours, the resulting material was diluted with 3 mL of quartz sand and then placed in a fixed-bed reactor. The temperature was raised to 600 °C at 5 °C / min under He and kept for 8 h, and the molar ratio of cobalt to silicon dioxide was 5:3. Porous carbon-supported cobalt catalyst, the weight of the obtained catalyst is 0.12g, and the volume is about 0.3mL.

[0047] The BET method was used to calculate the specific surface area of the catalyst, and the BJH method was used to calculate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com