Bimetal-doped VIB-group metal oxide nano-material, preparation method therefor and application of bimetal-doped VIB-group metal oxide nano-material

A nano-material and bimetallic technology, applied in the field of inorganic oxide materials and their preparation, can solve the problems of reducing free electron concentration, poor infrared light absorption ability, and limited number of free electrons, and achieve narrow particle size distribution and near-infrared absorption High capacity and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of lithium potassium tungsten bronze Li 0.12 K 0.2 WO 3 Nanoparticles, the preparation method of which is as follows:

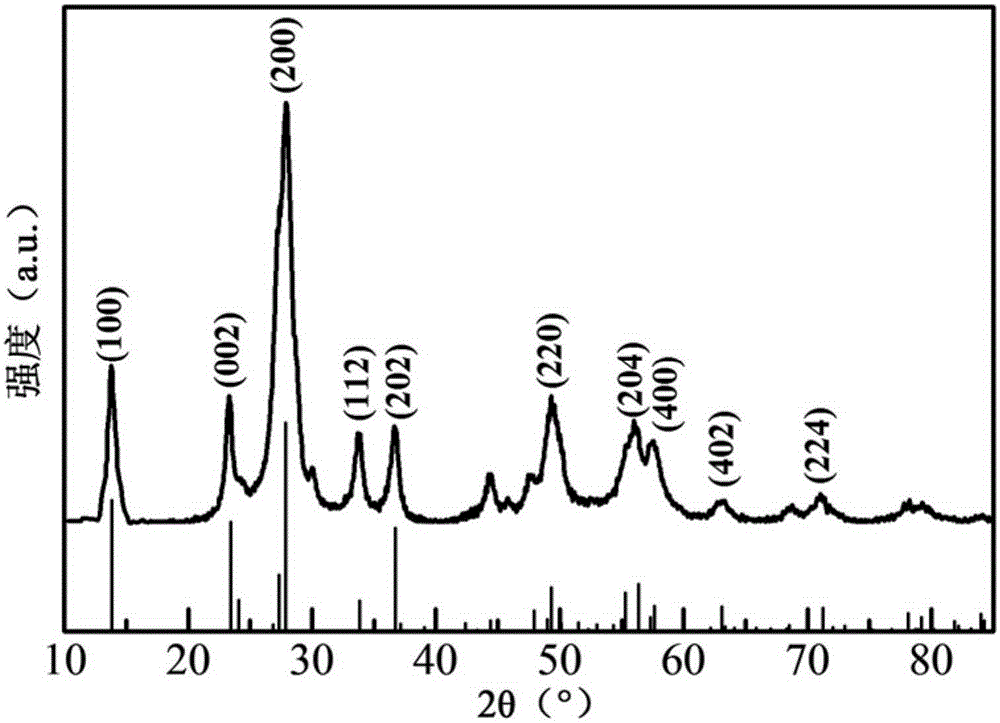

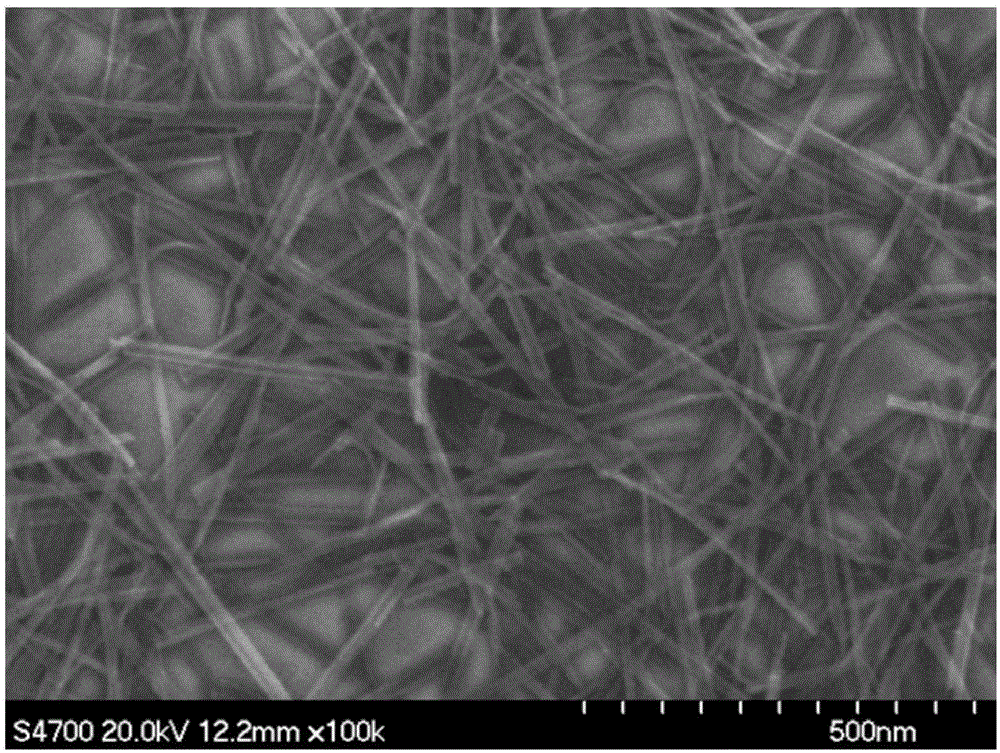

[0045] Prepare 80ml of 0.15mol / L potassium tungstate aqueous solution, and use 3mol / L hydrochloric acid solution to adjust the pH of the solution to 2.5. Then add 0.0015mol lithium nitrate and 0.002mol potassium nitrate, stir and mix evenly at room temperature; then add 0.15mol glycerol, then move the solution to a 150ml hydrothermal reaction kettle, and react in an oven at 160°C for 24h. After the reaction was completed and cooled to room temperature, the product was centrifuged, washed four times with 50 ml of deionized water and 50 ml of absolute ethanol, and dried in vacuum at 70°C. XRD and SEM tests were carried out on the obtained lithium potassium tungsten bronze powder particles. Such as figure 1 It is the XRD spectrum of the product of this example. The XRD test results show that its structure is similar to the peak position of NO...

Embodiment 2

[0047] A kind of lithium potassium tungsten bronze Li 0.29 K 0.23 WO 3 Nanoparticles, the preparation method of which is as follows:

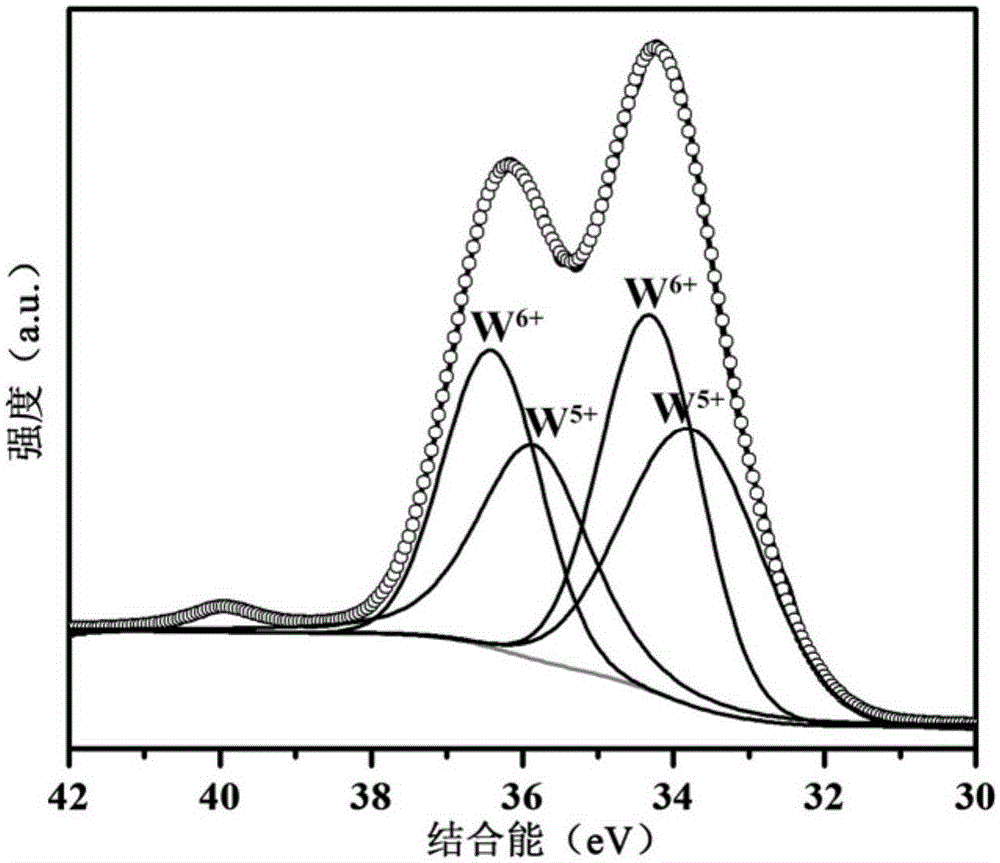

[0048] Prepare 80ml of 0.15mol / L potassium tungstate aqueous solution, and use 3mol / L hydrochloric acid solution to adjust the pH of the solution to 2.5. Then add 0.004mol lithium nitrate and 0.003mol potassium nitrate, stir and mix evenly at room temperature; then add 0.15mol glycerol, then move the solution to a 150ml hydrothermal reaction kettle, and react in an oven at 160°C for 24h. After the reaction was completed and cooled to room temperature, the product was centrifuged, washed four times with 50 ml of deionized water and 50 ml of absolute ethanol, and dried in vacuum at 70°C. The results of XRD and TEM tests on the powder particles show that the crystal structure, appearance, size and properties of the particles are similar to the particles prepared in Example 1. Carry out XPS test on it, the test result is as follows image 3 As...

Embodiment 3

[0050] A kind of sodium potassium tungsten bronze Na 0.2 K 0.07 WO 3 Nanoparticles, the preparation method of which is as follows:

[0051] Prepare 80ml of 0.25mol / L sodium tungstate aqueous solution, and use 3mol / L hydrochloric acid solution to adjust the pH of the solution to 7.5. Then add 0.002mol potassium sulfate and 0.0045mol sodium sulfate, stir and mix evenly at room temperature, then add 0.075mol reducing agent ethylenediamine, then move the solution to a 150ml hydrothermal reaction kettle, and react in an oven at 180°C for 20h. After the reaction is completed and cooled to room temperature, the product is centrifuged and washed, and the powder particles are vacuum-dried at 70°C. Carry out SEM test on the powder particles, the results are as follows Figure 5 As shown, the obtained sodium potassium tungsten bronze particles are rod-shaped particles with a length of 50-500 nm and a width of 50-100 nm. Its shielding effect on near-infrared light is similar to that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com