Preparation method of amino acid surfactant

A surfactant and amino acid technology, applied in the field of surfactant preparation, can solve the problems of "three wastes" discharge, difficult purification, long process, etc., and achieve the effect of solving environmental and health problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

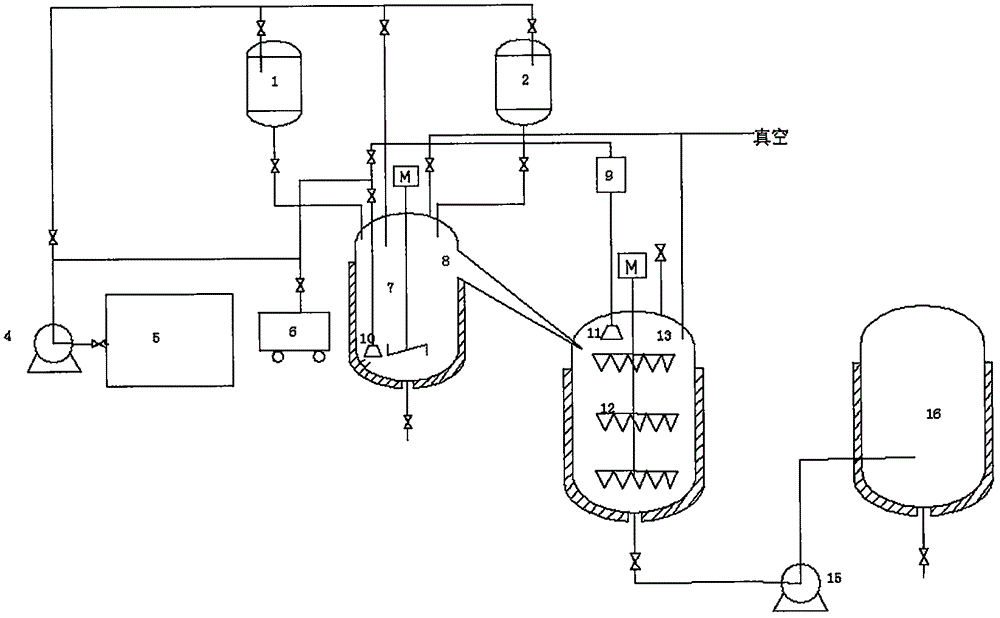

[0023] In synthesis reactor 1, add the N-methyl taurate sodium solution (40%) of 400kg, 50kg deionized water, then dropwise the 32% liquid caustic soda of 200kg lauroyl chloride and 100kg by overhead tank, dropwise process control The pH is 9-12, the temperature is ≤60°C, and the dropping time is controlled at 3 hours; after the dropping, add 10kg of concentrated hydrochloric acid (36%) to adjust the pH of the system to 7.5-8.5, raise the temperature to 70°C, and keep the temperature for aging for 2 hours; The temperature was lowered to 40° C. to obtain 760 kg of the crude product of sodium lauroyl methyl taurate;

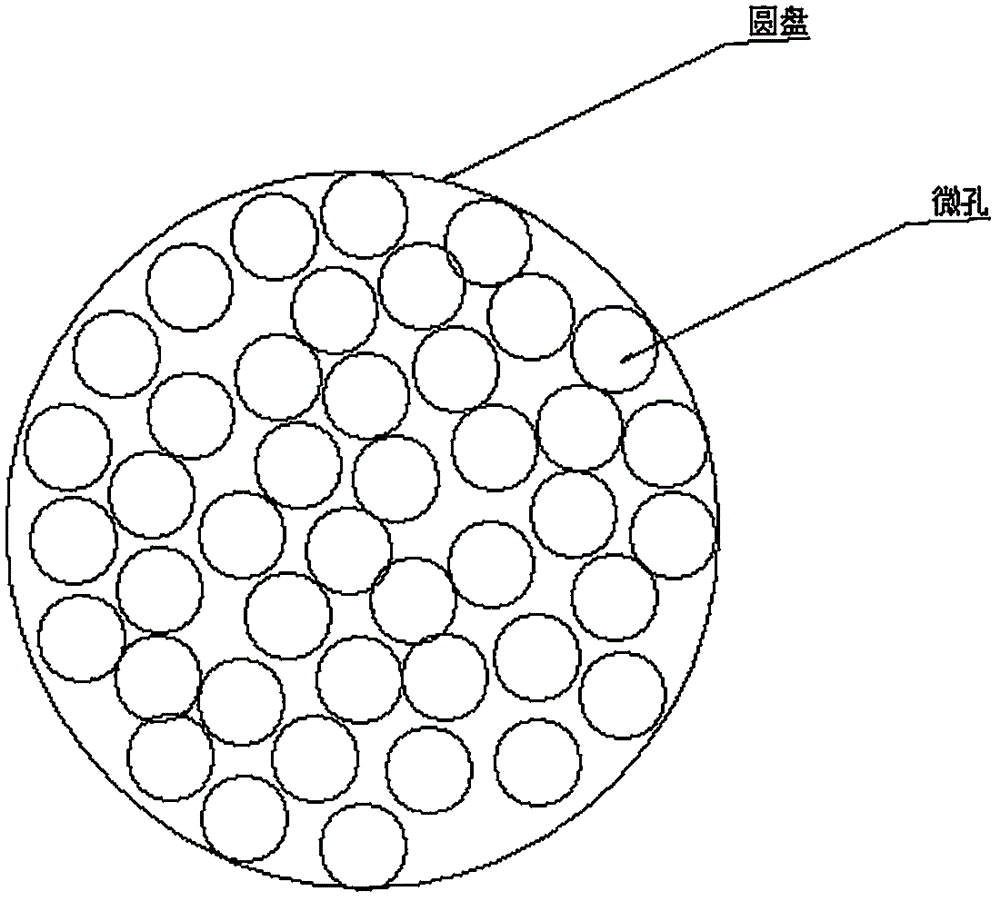

[0024] Turn on the air compressor, pass the compressed air into the disc aerator, ventilate for 5 to 10 minutes, you can see that the bubbles start to reach the overflow port, and when the foam overflows to the reactor 2 through the trumpet overflow port, start the reaction The foam-breaking stirrer of still 2, open water circulation vacuum pump and steam heating s...

Embodiment 2

[0027] In synthesis reactor 1, add the liquid caustic soda of 500kg, the deionized water of 120kg, the L-glutamic acid of 300kg, drip the 32% liquid caustic soda of 370kg cocoyl chloride (M=218) and 300kg by header tank then, During the dropping process, the pH is controlled at 9.5-11, the temperature is at 50-60°C, and the dropping time is controlled at 6 hours; at the end of the dropping, the temperature is kept at 50-60°C for aging reaction for 4 hours, and the temperature is raised to 70-75°C, and the temperature is kept at 2 hour; be cooled to 55~60 ℃ and obtain the crude product 1590kg of sodium cocoyl glutamate;

[0028] Turn on the air compressor, pass the compressed air into the disc aerator, ventilate for 5 minutes, you can see that the bubbles begin to reach the overflow port, and when the foam overflows to the reactor 2 through the trumpet overflow port, open the reactor 2 The bubble-breaking stirrer is used, and the water circulation vacuum pump and steam heating ...

Embodiment 3

[0031] In the synthesis reaction kettle 1, add 190kg of liquid caustic soda, 860kg of deionized water, and 125kg of glycine, then drop 325kg of myristoyl chloride and 200kg of 32% liquid caustic soda through the overhead tank, and control the pH at 9.5 to 11 during the dropping process. , the dropping time is 2 hours; the dropping is completed, the temperature is kept at 50-60°C for aging reaction for 4 hours, the temperature is raised to 80-85°C, and the temperature is kept for 2 hours; the temperature is lowered to 55-60°C to obtain 1700kg of crude product of sodium myristoyl glycinate;

[0032]Turn on the air compressor, pass the compressed air into the disc aerator, ventilate for 5 to 10 minutes, you can see that the bubbles start to reach the overflow port, and when the foam overflows to the reactor 2 through the trumpet overflow port, start the reaction The foam-breaking stirrer of still 2, open water circulation vacuum pump and steam heating system simultaneously. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com