Method for preparing high-dispersibility polystyrene magnetic microsphere

A technology of magnetic microspheres and polystyrene, which is applied in the field of preparation of highly dispersed polystyrene magnetic microspheres, and can solve the problems of poor crystallinity, low dispersion and weak magnetic response of magnetic polymer microsphere nanoparticles , to achieve good magnetic response properties, uniform particle size distribution, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: polystyrene wraps magnetic Fe 3 o 4 preparation of

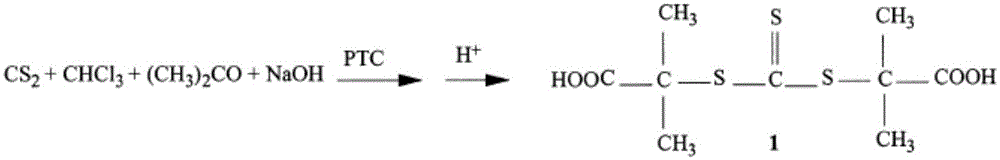

[0022] Dissolve 2.74g of carbon disulfide, 10.75g of chloroform, 5.23g of acetone and 0.241g of tetrabutylammonium bisulfate in 12mL of toluene, and slowly add 20.16g of 50% sodium hydroxide (10-15min) under stirring in an ice-water bath in a nitrogen atmosphere, After the sodium hydroxide was added dropwise, react for 12 hours to obtain a yellow solid, add 90mL deionized water to dissolve it, let stand to separate and take the water phase, add 12mL concentrated hydrochloric acid under nitrogen protection, stir and react for 30min, obtain a yellow precipitate, wash, filter, Dry to constant weight to get S, S'-di(ɑ,ɑ'-dimethyl-ɑ"-acetic acid) trithiocarbonate (CTA). The reaction principle is as follows figure 1 shown.

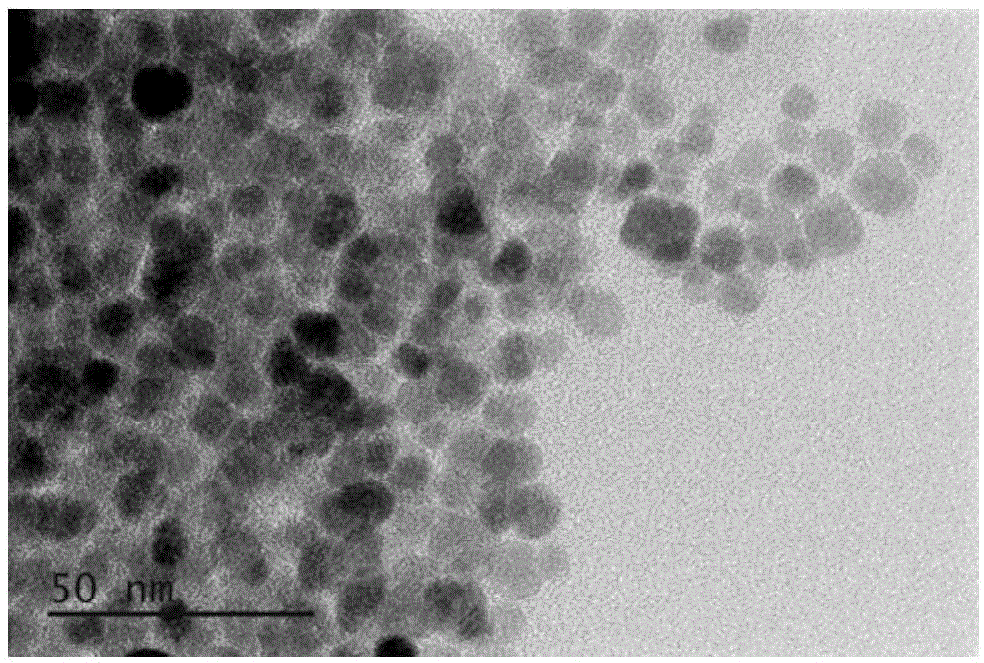

[0023] 10.8g FeCl 3 ·6H 2 O, 3.9 g FeCl 2 4H 2 O was dissolved in 200mL of deionized water, 3.5g of oleic acid (OA) was weighed and dissolved in 120mL of acetone, and then the two p...

Embodiment 2

[0027] Embodiment 2: polystyrene encapsulation magnetic Fe 3 o 4 preparation of

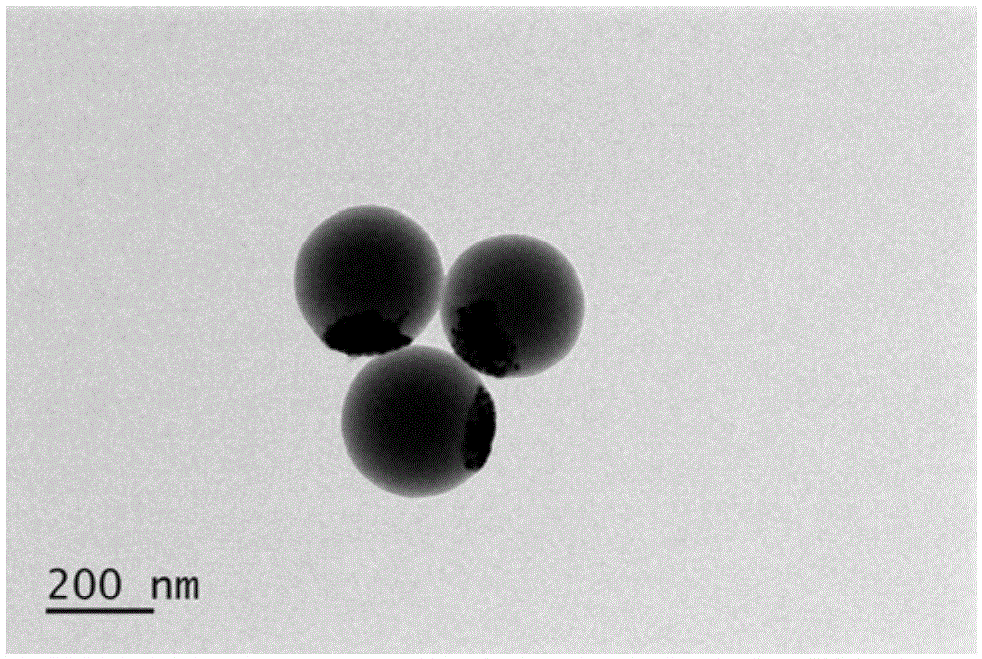

[0028] 8.00g styrene, 0.40g hexadecane, 0.64g OA wrapped Fe 3 o 4 , 0.08g CTA, and 0.12g azobisisobutylamidine hydrochloride were added into a three-necked flask and ultrasonicated for 5 minutes to make an oil phase; 0.16g ILs was dissolved in 48.0g deionized water to make an aqueous phase; then the two phases Mix and react under vigorous stirring (600 rpm) under nitrogen atmosphere for 1 h. Then sonicate in an ice-water bath for 60 minutes, and then stir (400rpm) at 70°C for 20 hours. After the reaction is completed, cool to room temperature to obtain khaki microspheres, which are washed with deionized water to obtain polystyrene-coated magnetic Fe. 3 o 4 Microspheres.

[0029] The magnetic properties and stability of the microspheres were determined by using a magnetic field. Depend on Figure 4 b and Figure 5 It can be seen that the latex has high magnetic response, good stability, c...

Embodiment 3

[0030] Embodiment 3: polystyrene encapsulation magnetic Fe 3 o 4 preparation of

[0031] 8.00g styrene, 0.40g hexadecane, 0.64g OA wrapped Fe 3 o 4 , 0.08g CTA, 0.016g azobisisobutylimidazoline hydrochloride were added into a three-necked flask and ultrasonically 10min to make an oil phase; 0.16g ILs was dissolved in 64.0g deionized water to make an aqueous phase; then the two They were mixed together and reacted for 1 h under vigorous stirring (600 rpm) under a nitrogen atmosphere. Then sonicate in an ice-water bath for 60 minutes, and then stir (400rpm) at 70°C for 20 hours. After the reaction is completed, cool to room temperature to obtain khaki microspheres, which are washed with deionized water to obtain polystyrene-coated magnetic Fe. 3 o 4 Microspheres.

[0032] The magnetic properties and stability of the microspheres were determined by using a magnetic field. Depend on Figure 4 c and Figure 5 It can be seen that the latex has high magnetic response, good s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com