Water gas preparation process based on dry coke quenching and coking coal dehumidification

A technology for dry quenching coke and preparation process, applied in the field of coal chemical industry, can solve the problems of ineffective utilization of the residual heat of cold coke in the dry quenching furnace, large coke consumption, etc., to improve drying effect and efficiency, reduce emissions, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

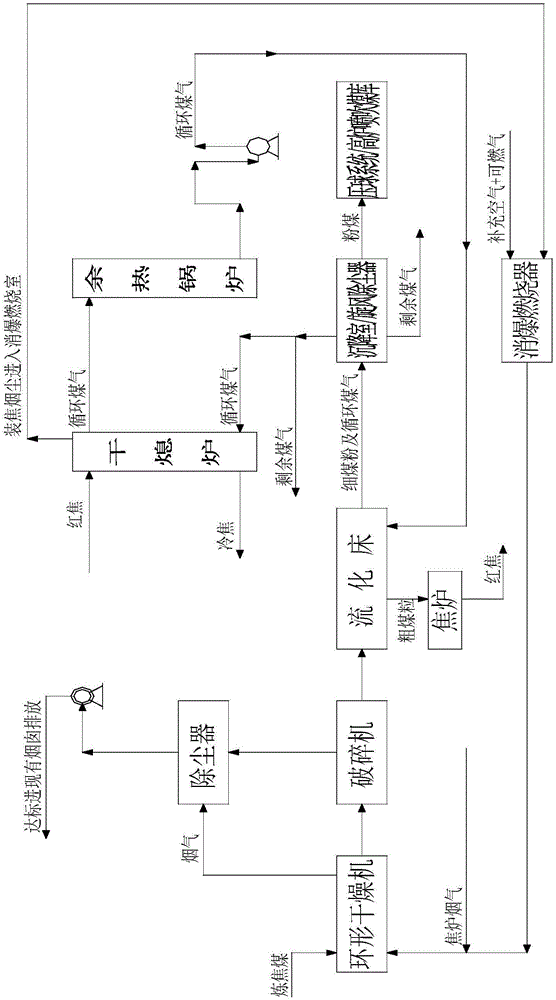

[0022] The process of the present invention will be further explained below in conjunction with the accompanying drawings: the coking coal (water content is 10wt%) is first dried by coke oven flue gas from the horizontal flue of the coke oven in a ring dryer, and the water content is reduced to 7-8wt% , And then crushed to below 3mm by a crusher. After crushing, the coking coal is sent to a fluidized bed for fluidization, drying, and classification. It is dried by circulating gas to a water content of below 3wt%, and then classified to obtain coarse coal particles (particle size 0.3 -3mm) and fine coal powder (diameter <0.3mm). The coarse coal particles are sent to the coke oven to obtain red coke, and the red coke is sent to the dry quenching furnace to be quenched by the circulating gas to obtain a cold temperature lower than 150℃ Coke; the circulating gas (temperature 900℃) from the dry quenching furnace enters the waste heat boiler by-product steam, and the circulating gas (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com