Genetically engineered bacterium used for producing 3-hydroxypropionic acid (3-HP) by fermentation, constructing method and application of genetically engineered bacterium

A technology of genetically engineered bacteria and hydroxypropionic acid is applied in the field of genetic engineering to achieve the effects of avoiding insufficient enzyme activity, increasing yield, and strengthening industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

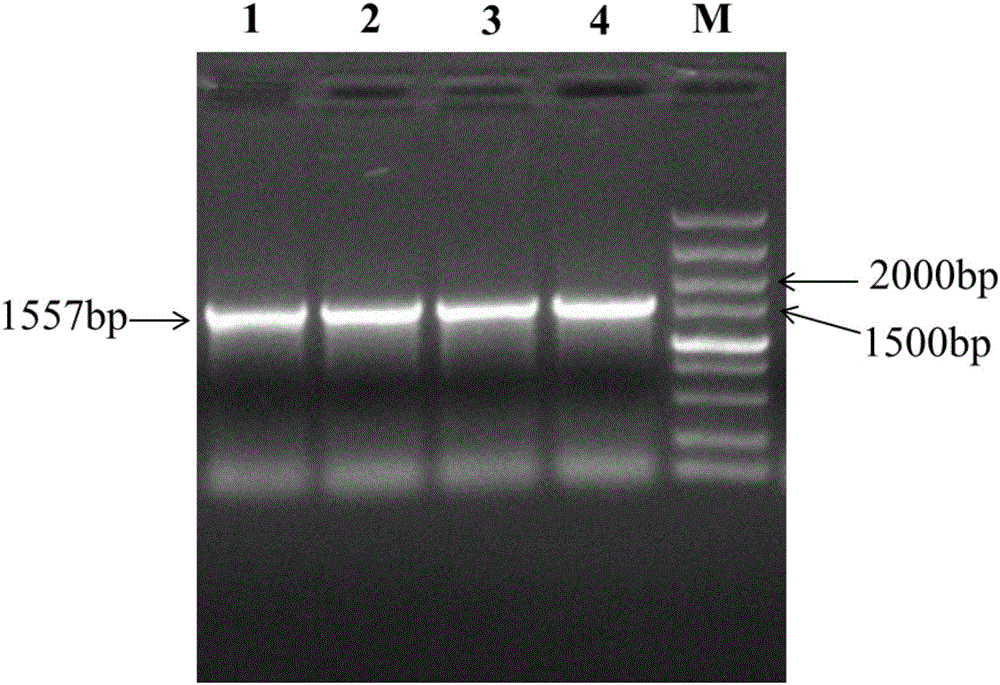

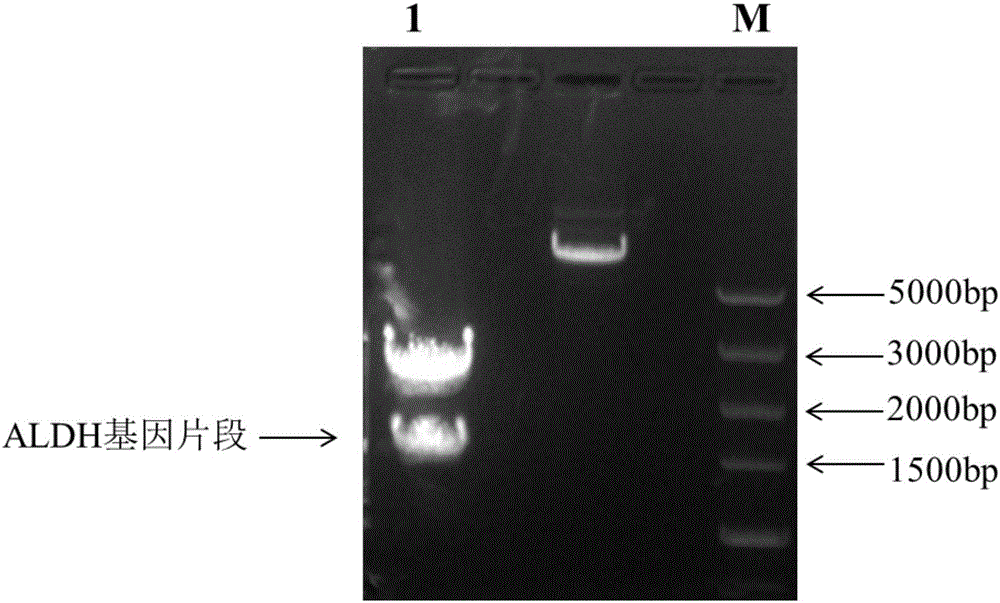

[0036] Embodiment 1 Construction of recombinant plasmid pET30a-ALDH-DHAB

[0037] 1. Using the genomic DNA of Klebsiella pneumoniae as a template to amplify the DHAB gene

[0038] Extract the genomic DNA of Klebsiella pneumoniae, use the genomic DNA of Klebsiella pneumoniae as a template, synthesize primers, amplify the DHAB gene sequence, and the primers are as follows:

[0039] P1:ExDHABF:5'-ACGCGGAGCTCATGAAAAGATCAAAACGA-3' (SEQ ID NO.2)

[0040] P2:ExDHABR:5'-CGGCAAGCTTTTAGCTTCCTTTACGCAG-3' (SEQ ID NO.3)

[0041] The upstream primer (P1) introduces the Sac I site, and the downstream primer (P2) introduces the Hind III restriction site. 5 and 4 enzyme cutting site protection bases were introduced at the 5' end respectively.

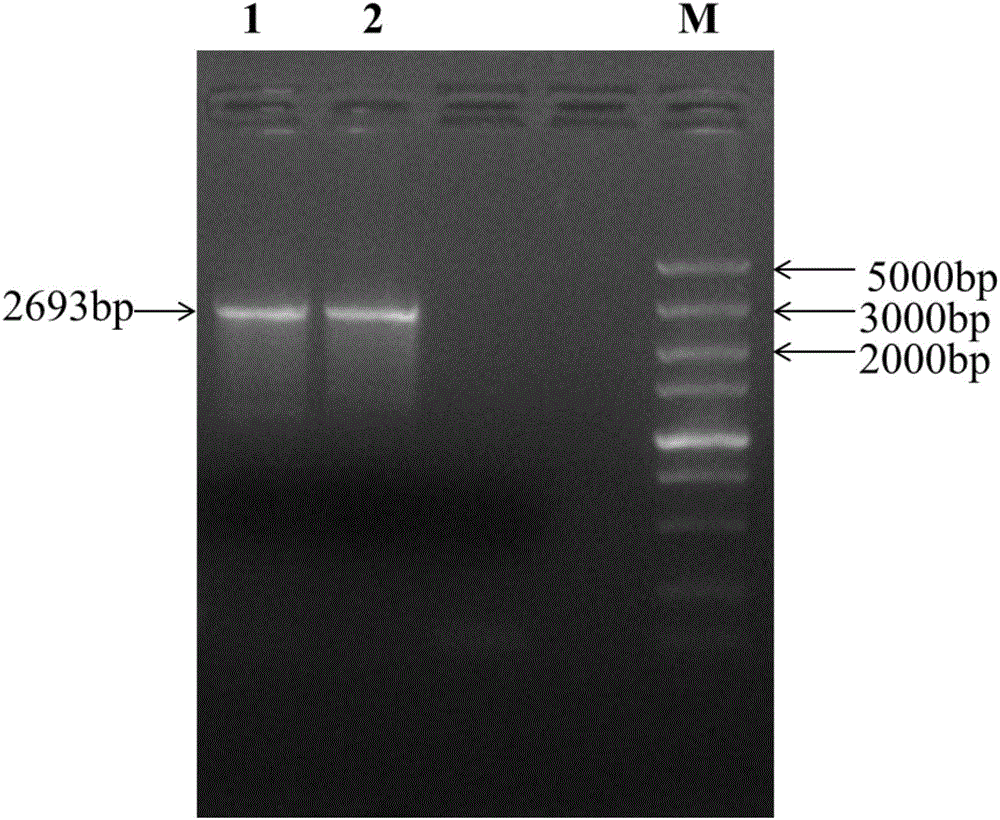

[0042] The PCR product was analyzed by gel electrophoresis, and the size of the DHAB gene was about 2700bp ( figure 1 ), which is the expected size. After the PCR products were purified, they were sent to Shanghai Sangon Biotechnology Co., Ltd. for...

Embodiment 2

[0067] Induced expression of embodiment 2 transformants

[0068] Pick the single-clonal colony of the recombinant strain from the freshly transformed plate, add 100mL LB medium containing 25μg / mL kanamycin at 37°C, 150rpm, shake and culture for 10-12 hours, until the bacterial solution OD 600 When the value reaches 0.6-0.9, IPTG is added to make the final concentration of IPTG 1.0 mM, induced at 15-25° C. for 15-20 hours, and the engineering bacteria of the present invention are obtained. (Enzyme activity determination is not provided here, the following fermentation experiments can illustrate the characteristics of 3-HP production)

Embodiment 3

[0069] Embodiment 3: engineering bacterium fermentation of the present invention produces the reaction of 3-hydroxypropionic acid

[0070] Add 100mL M9 medium (g.L -1 , glycerin 50, yeast paste 5.0, KH 2 PO 4 7.5, MgSO 4 ·7H 2 O 0.25, (NH 4 ) 2 SO 4 2.0, FeSO 4 ·7H 2 O 0.005, CaCl 20.1, vitamin B120.015, deionized water 1000mL, pH7.0), insert the BL21 (pET30a-ALDH-DHAB) bacterial strain of logarithmic growth phase by 10% inoculum size (same as cultivation method among the embodiment 2), Then cultured on a shaking table at 37° C. and 140 rpm for 60 h. The fermentation broth induced without adding IPTG was used as a control, and the control group was also cultured under the above conditions.

[0071] Samples were taken at regular intervals during the culture, and the 3-HP concentration was determined by HPLC. The yield of 3-HP produced by the genetically engineered bacteria is shown in Table 1 (the values in the table are the average values of three repetitions)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com