Octahedral nanometer alloy, porous octahedral nanometer alloy as well as preparation method and purpose thereof

A nano-alloy and octahedral technology, which is applied in the field of catalytic materials, can solve the problems of unfavorable industrial production, strict requirements on dropping speed, complicated operation and the like, and achieves the effects of easy industrial production, simple operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Dissolve platinum salt, silver salt, polyacrylamine hydrochloride and ascorbic acid in water, stir evenly to obtain a mixed solution, the concentration of platinum ions in the mixed solution is 0.0015mol / L, the concentration of silver ions is 0.0015mol / L, polyacrylamine The hydrochloride concentration is 10g / L, and the ascorbic acid concentration is 0.75mol / L. React at 180°C for 4h. After the reaction, cool to room temperature, wash the reaction product with water and ethanol three times, centrifuge to remove the supernatant, add nitric acid solution with a mass fraction of 35%, and sonicate at room temperature for 15 min. Centrifuge to remove the supernatant, wash, and repeat the operation of centrifugation and washing to neutrality to obtain a porous octahedral platinum-silver nano-alloy.

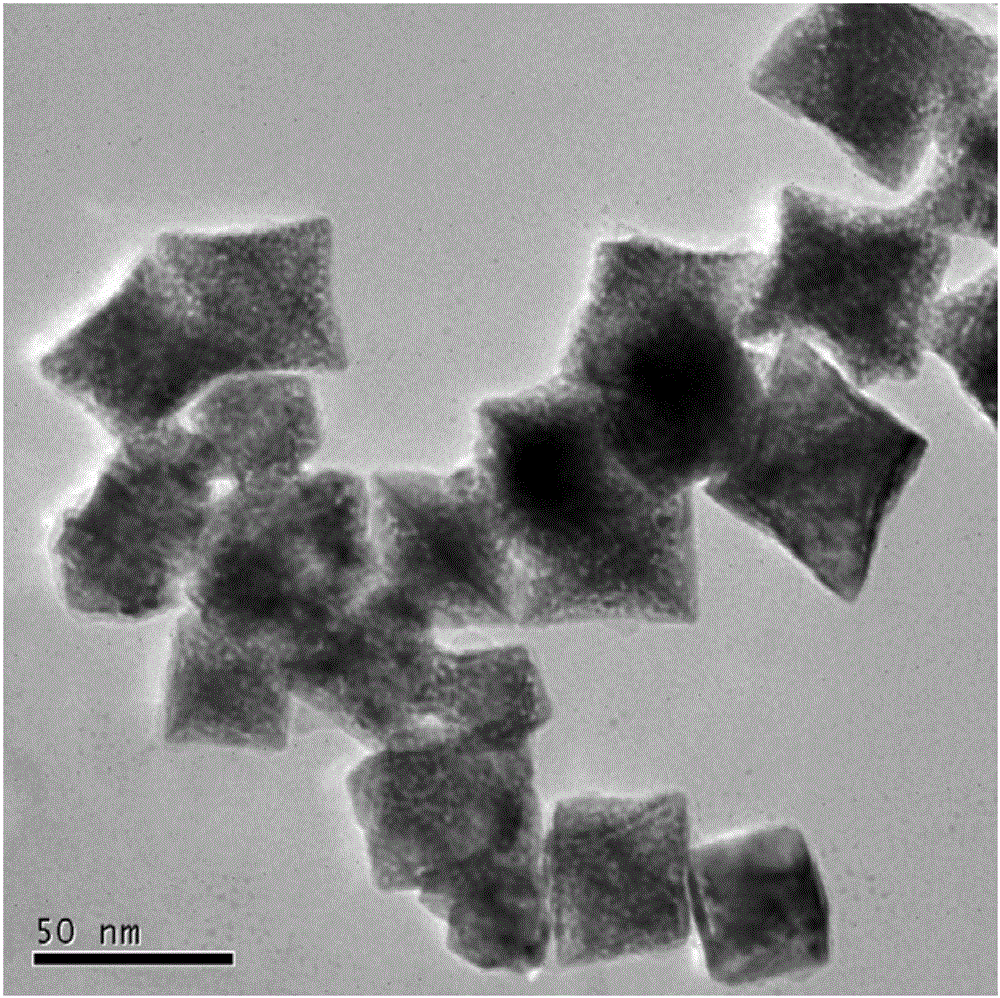

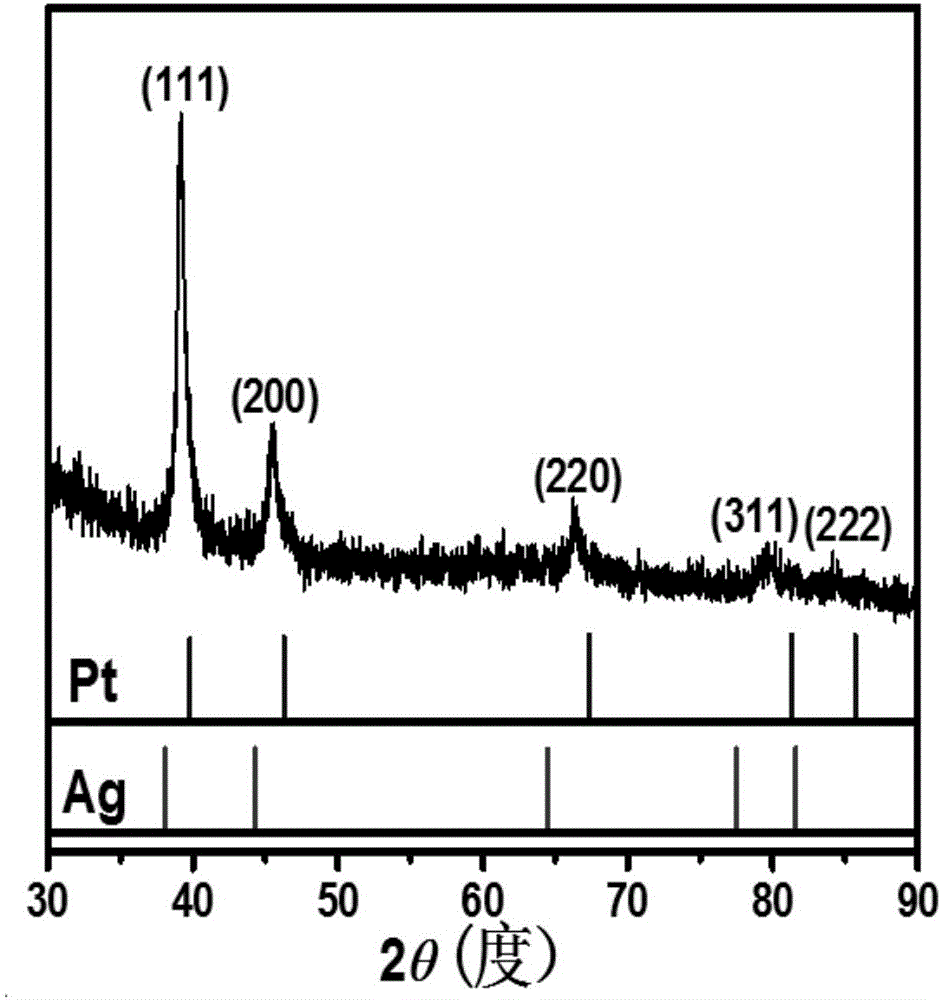

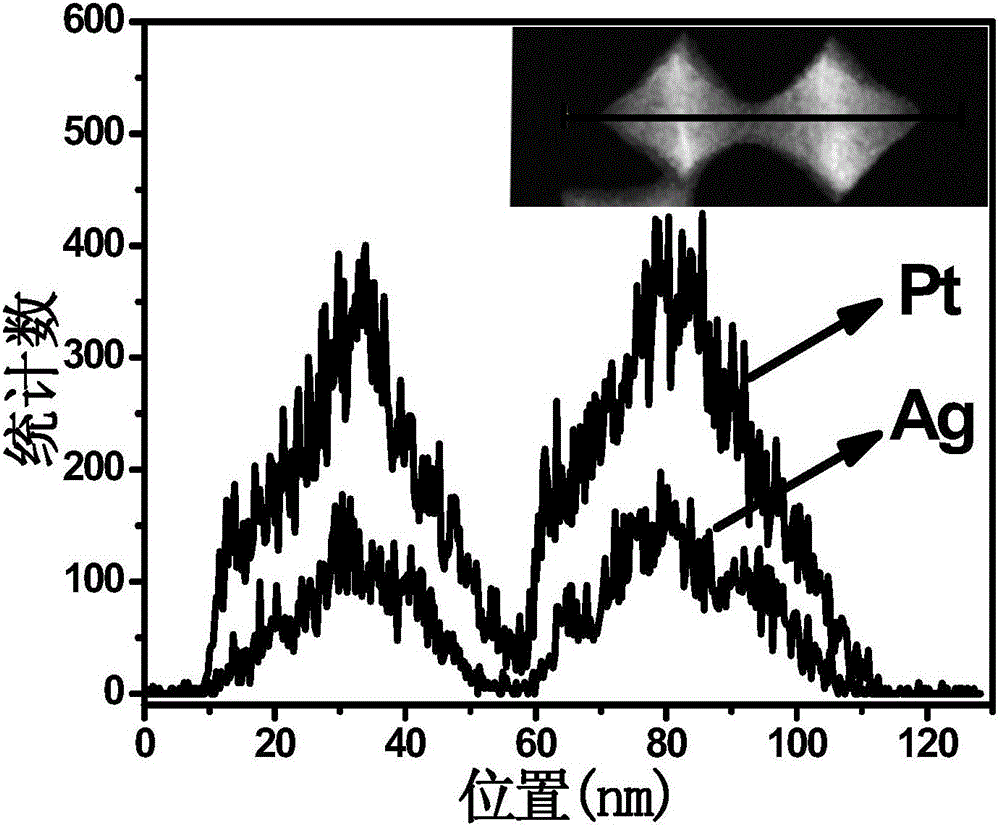

[0077] figure 1 For the transmission image of the porous platinum-silver nanoalloy prepared in this example, it can be clearly seen from the figure that the platinum-silver nanop...

Embodiment 2

[0086] Palladium salt, zinc salt, polyethylene glycol and ascorbic acid are dissolved in water, stir evenly, obtain mixed solution, in the mixed solution, palladium ion concentration is 0.00015mol / L, zinc ion concentration is 0.0005mol / L, polyethylene glycol concentration is 1g / L, the concentration of ascorbic acid is 0.1mol / L. React at 120°C for 4h. After the reaction, cool down to room temperature, wash the reaction product with water and ethanol three times, centrifuge to remove the supernatant, add 20% hydrochloric acid solution, and sonicate at room temperature for 10 min. Centrifuge to remove the supernatant, wash, and repeat the operations of centrifugation and washing to neutrality to obtain a porous octahedral palladium-zinc nano-alloy.

[0087] The porous octahedral palladium-zinc nano-alloy that present embodiment obtains, adopts BET specific surface area test method to record its specific surface area to be 10m 2 / g, with a porosity of 65%, the maximum reaction r...

Embodiment 3

[0089] Dissolve gold salt, copper salt, polyvinylpyrrolidone and sodium citrate in benzyl alcohol, stir well to obtain a mixed solution, the gold ion concentration in the mixed solution is 0.015mol / L, the copper ion concentration is 0.010mol / L, polyethylene The concentration of pyrrolidone is 25g / L, and the concentration of sodium citrate is 2mol / L. React at 200°C for 1 h. After the reaction, cool to room temperature, wash the reaction product with water and ethanol four times, centrifuge to remove the supernatant, add sulfuric acid solution with a mass fraction of 50%, and ultrasonicate at room temperature for 5 minutes. Centrifuge to remove the supernatant, wash, and repeat the operation of centrifugation and washing to neutrality to obtain a porous octahedral gold-copper nano-alloy.

[0090] The porous octahedral gold-copper nano-alloy that present embodiment obtains, adopts BET specific surface area test method to measure its specific surface area to be 9m 2 / g, with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com