Method for preparing Aurivillius structure oxyfluoride by low-temperature liquid phase

A technology of oxyfluoride and low-temperature liquid phase, which is applied in chemical instruments and methods, niobium compounds, tantalum compounds, etc., can solve the problems of complex preparation process, high equipment requirements, and difficult synthesis, and achieve simple process and low production cost , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

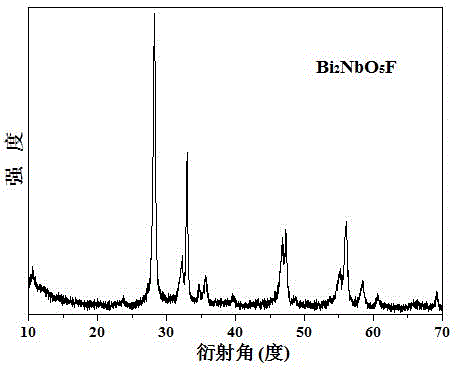

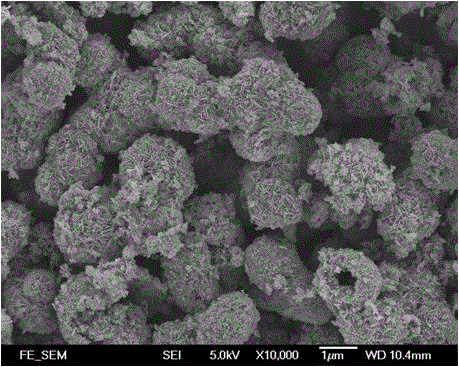

[0025] Embodiment 1: niobium bismuth oxyfluoride (Bi 2 NbO 5 F) Preparation.

[0026] 1) Weigh 0.5 mmol of niobium pentoxide, dissolve it in 5 mL of hydrofluoric acid, remove the remaining hydrofluoric acid as much as possible by heating and evaporation, and finally dilute to 10 mL with water.

[0027] 2) Weigh 2mmol of bismuth nitrate and dissolve it in 30mL of ethylene glycol.

[0028] 3) Add the solution in step 1) dropwise to the solution in step 2) under magnetic stirring, and mix well.

[0029] 4) The obtained mixed solution was transferred to a 50mL reaction autoclave, sealed, and reacted at a constant temperature of 150°C for 12 hours, and naturally cooled to room temperature after the reaction.

[0030] 5) The reaction product was suction filtered, washed alternately with water and ethanol several times, and dried at 60°C for 5 hours to obtain Bi 2 NbO 5 F powder product.

Embodiment 2

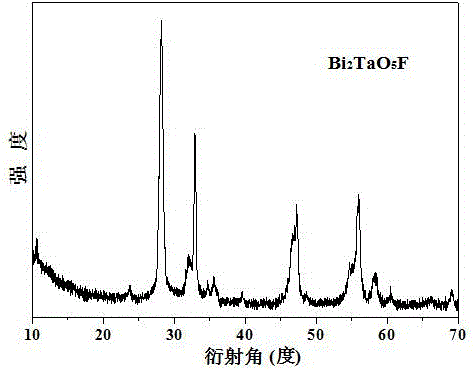

[0031] Embodiment 2: tantalum bismuth oxyfluoride (Bi 2 TaO 5 F) Preparation.

[0032] 1) Weigh 0.5mmol tantalum pentoxide, dissolve it in 5mL hydrofluoric acid, remove the remaining hydrofluoric acid as much as possible by heating and evaporation, and finally dilute to 10mL with water.

[0033] 2) Weigh 2mmol of bismuth nitrate and dissolve it in 30mL of ethylene glycol.

[0034] 3) Add the solution in step 1) dropwise to the solution in step 2) under magnetic stirring, and mix well.

[0035] 4) The obtained mixed solution was transferred to a 50mL reaction autoclave, sealed, and reacted at a constant temperature of 150°C for 12 hours, and naturally cooled to room temperature after the reaction.

[0036] 5) The reaction product was suction filtered, washed alternately with water and ethanol several times, and dried at 60°C for 5 hours to obtain Bi 2 TaO 5 F powder product.

Embodiment 3

[0037] Embodiment 3: niobium bismuth oxyfluoride (Bi 2 NbO 5 F) Preparation.

[0038] 1) Weigh 1 mmol of niobium pentoxide, dissolve it in 7 mL of hydrofluoric acid, remove the remaining hydrofluoric acid as much as possible by heating and evaporation, and finally dilute to 20 mL with water.

[0039] 2) Weigh 4mmol of bismuth chloride and dissolve it in 20mL of ethanol.

[0040]3) Add the solution in step 1) dropwise to the solution in step 2) under magnetic stirring, and mix well.

[0041] 4) The obtained mixed solution was transferred to a 50mL reaction autoclave, sealed, and reacted at a constant temperature of 150°C for 12 hours, and naturally cooled to room temperature after the reaction.

[0042] 5) The reaction product was suction filtered, washed alternately with water and ethanol several times, and dried at 60°C for 5 hours to obtain Bi 2 NbO 5 F powder product.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap