Treatment method of high-acidity high-salinity copper-containing organic wastewater

A technology of organic wastewater and treatment methods, applied in water/sewage treatment, water treatment parameter control, special compound water treatment, etc., can solve the problem of low copper recovery rate in the replacement of copper acid water, affecting the discharge of COD in comprehensive sewage treatment stations, etc. , to achieve high recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

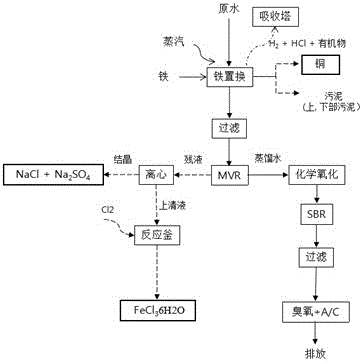

Image

Examples

Embodiment Construction

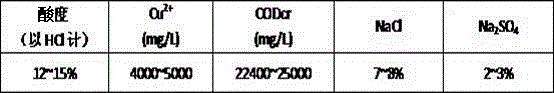

[0022] The following examples describe the present invention in detail, and its water quality index is not as a limitation of the present invention. The water quality conditions for replacing copper acid water in a saccharin factory are as follows:

[0023] Table 1 Water quality parameters of copper acid replacement water in a saccharin factory

[0024]

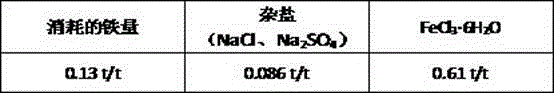

[0025] Iron replacement reaction. Weigh 400 kg of iron filings, put it into the FRP reaction tank, and pump it into the copper acid water shown in Table 1 to replace 3 m 3 , cover the cover, let in steam for 30 minutes, the temperature of the mixed liquid is 65~75°C, and turn off the steam. There is a violent reaction in the reaction tank, and a large number of bubbles are generated; the violent reaction time is 3-6 hours, and the reaction rate begins to slow down after 6 hours, and the temperature drops. The reaction time was 12 h, the pH was 2.5~3, and the reaction was nearly terminated. Clean up the scum on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com