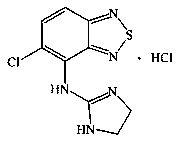

The method for high-purity industrialized production of tizanidine hydrochloride

A tizanidine hydrochloride, high-purity technology, applied in the field of drug synthesis, can solve the problems of low yield, unfavorable industrial production, unsuccinct reaction and the like, and achieve the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

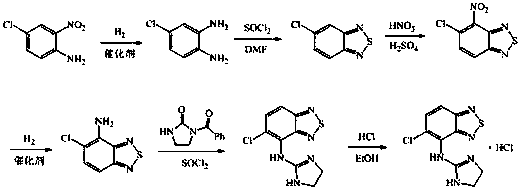

Method used

Image

Examples

Embodiment 1

[0050] a. Preparation of Intermediate II:

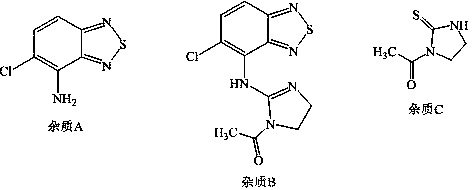

[0051] 310g (3.6mol) of 2-imidazolidinone, 930ml of a 50% aqueous solution of methacryloylpropyltrimethylammonium chloride, stirred at 15-25°C, and 520g (3.6mol) of dimethyl chlorophosphate was added thereto , keep stirring and react for 3 hours, then add 278g (1.5mol) of 4-amino-5-chloro-2,1,3-benzothiadiazole, maintain the temperature and stir the reaction, and identify the end point of the reaction by TLC (developer: dichloro Methane-methanol-triethylamine=1:1:0.1), the reaction was completed, filtered, the solid was washed with a small amount of water, and then washed with an appropriate amount of methanol, and dried in vacuum at 50-55°C for 6 hours to obtain 369g (1.454mol) of light yellow powder The yield of solid intermediate II (tizanidine) is 97.0%, mp: 221-222°C, and the HPLC content is 99.1%.

[0052] b, the preparation of compound I (tizanidine hydrochloride):

[0053] Intermediate II 360g (1.42mol), 95% ethanol 2160ml,...

Embodiment 2

[0060] Replace the 50% aqueous solution of methacryloylpropyltrimethylammonium chloride in the embodiment one step a with the 40% aqueous solution of tetrabutylammonium fluoride trihydrate, all the other steps are the same, make tizanidine hydrochloride 407g, total yield 95.5%, mp: 289~290°C (decomposition), HPLC content 99.9%, impurity A, impurity B and impurity C were not detected.

Embodiment 3

[0062] Diethyl chlorophosphate was used instead of dimethyl chlorophosphate in step a of Example 1, and the rest of the steps were the same to obtain 405 g of tizanidine hydrochloride, with a total yield of 95.3%, mp: 289-290°C (decomposition), HPLC The content is 99.8%, and impurity A, impurity B and impurity C are not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com