Method for preparing highly active humic acid serum

A technology of humic acid and high activity, which is applied in the fields of bio-organic part treatment, agriculture, organic fertilizer, etc. It can solve the problems of destroying physiological activity, large energy consumption, aging of fulvic acid, etc., and achieves a wide range of applications and saves natural resources , the effect of loosening the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Biomass sludge preparation:

[0056] After pretreatment, cutting and dust removal, the crop straw enters the separation section, where hemicellulose, cellulose and lignin are separated by physical and chemical methods, and the separated hemicellulose is in the liquid phase, that is, the hemicellulose liquid;

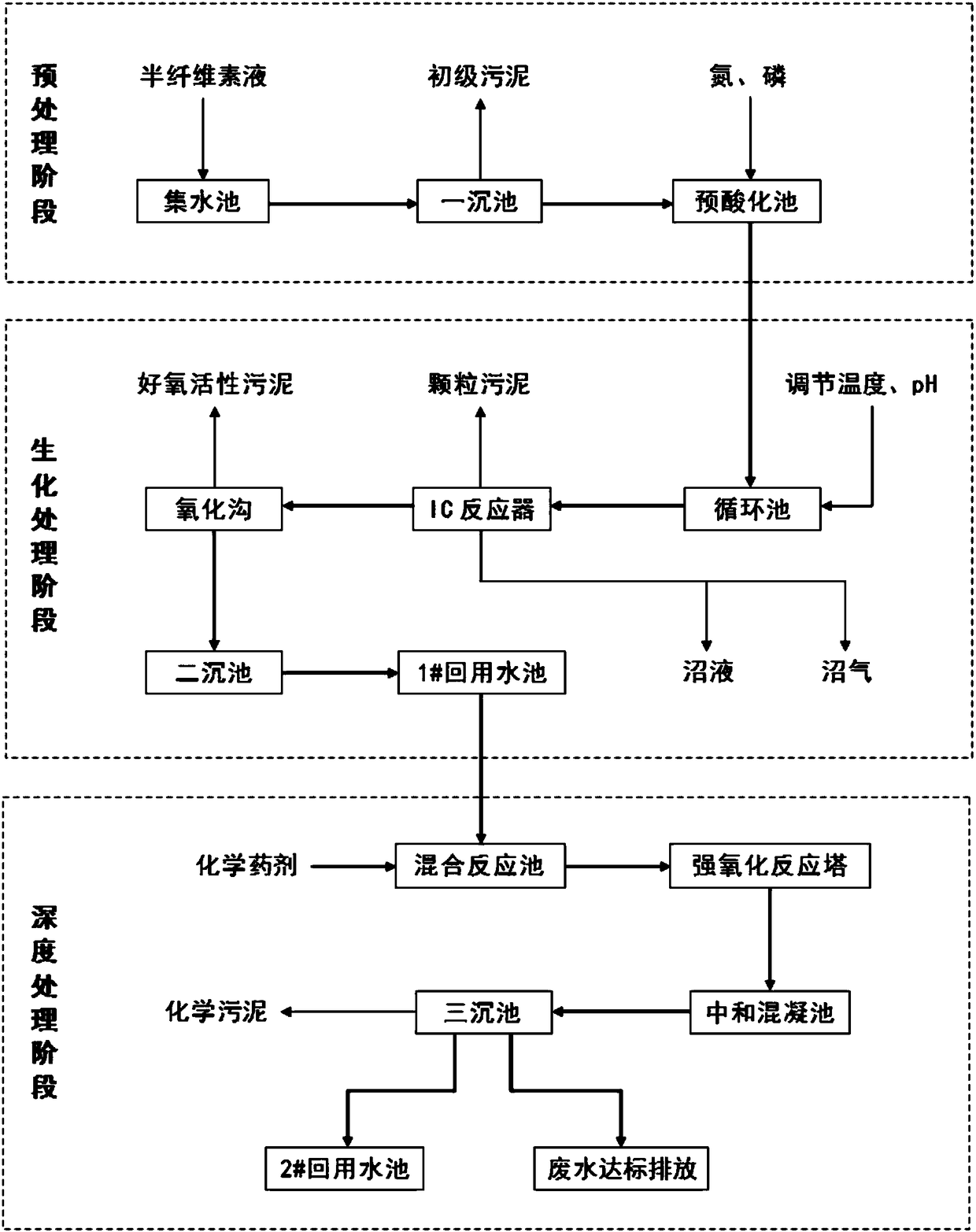

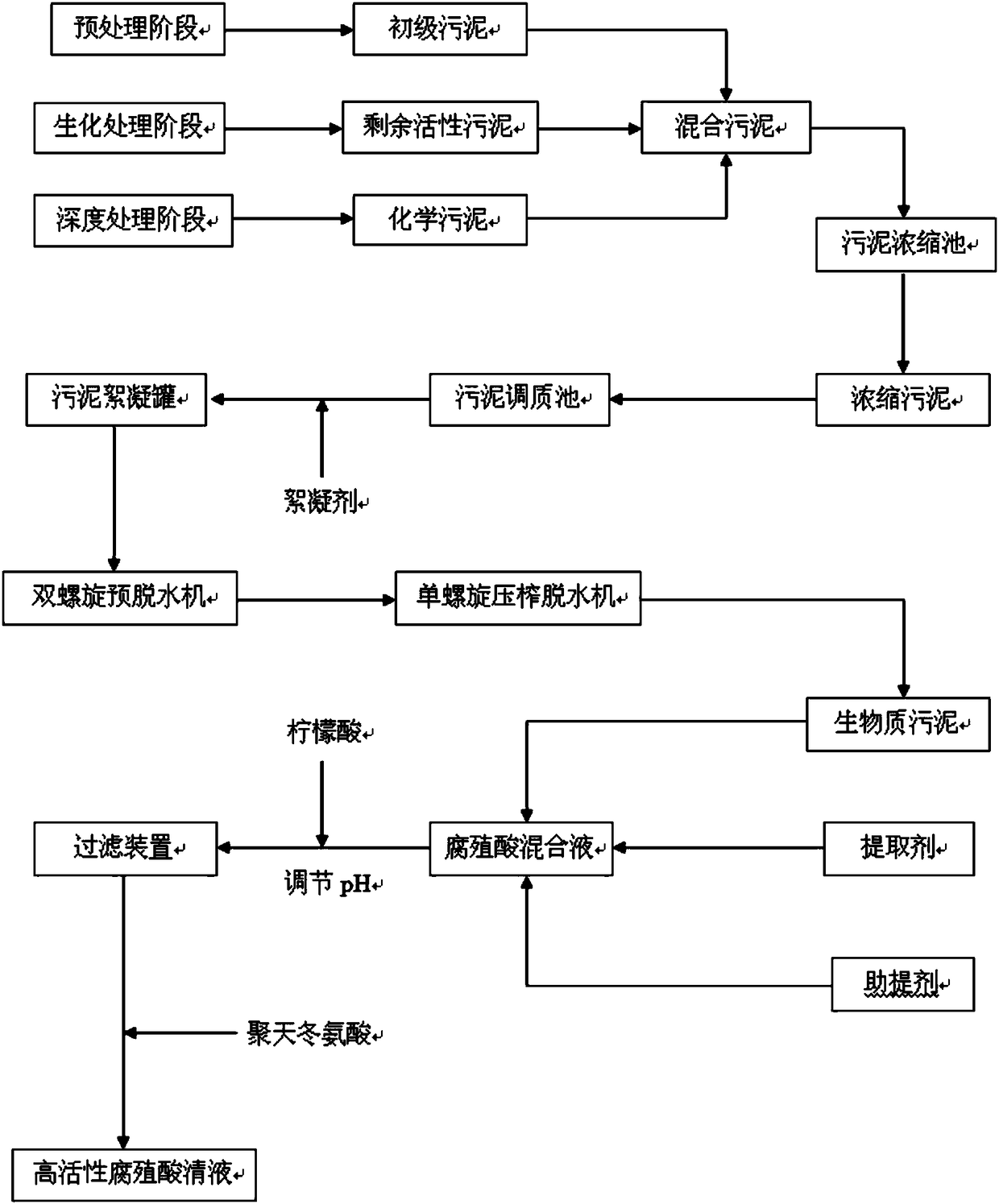

[0057] The hemicellulose liquid enters the wastewater treatment system and undergoes the pretreatment stage, biochemical treatment stage and advanced treatment stage successively. The pretreatment stage removes suspended solids to produce primary sludge, and the biochemical treatment stage removes a large amount of soluble COD to produce residual activated sludge. The treatment stage removes a small amount of pollutants that are not easily biodegradable to produce chemical sludge;

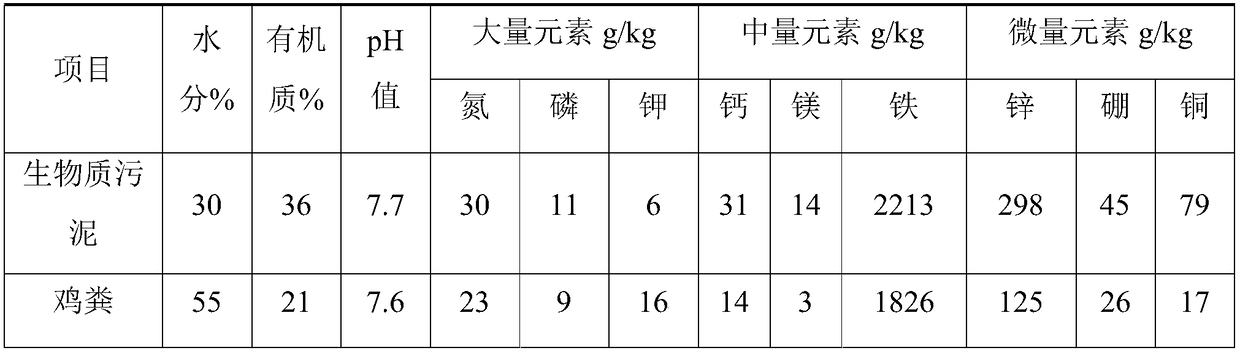

[0058] The primary sludge, residual activated sludge and chemical sludge are mixed, concentrated, flocculated, dehydrated, ventilated in the particle workshop, and dried to avoid d...

Embodiment 2

[0067] (1) Biomass sludge preparation:

[0068] After pretreatment, cutting and dust removal, the crop straw enters the separation section, where hemicellulose, cellulose and lignin are separated by physical and chemical methods, and the separated hemicellulose is in the liquid phase, that is, the hemicellulose liquid;

[0069] The hemicellulose liquid enters the wastewater treatment system and undergoes the pretreatment stage, biochemical treatment stage and advanced treatment stage successively. The pretreatment stage removes suspended solids to produce primary sludge, and the biochemical treatment stage removes a large amount of soluble COD to produce residual activated sludge. The treatment stage removes a small amount of pollutants that are not easily biodegradable to produce chemical sludge;

[0070] Primary sludge, residual activated sludge and chemical sludge are mixed, concentrated, flocculated, dehydrated, ventilated in the particle workshop, and dried to avoid direc...

Embodiment 3

[0079] (1) Biomass sludge preparation:

[0080] After pretreatment, cutting and dust removal, the crop straw enters the separation section, where hemicellulose, cellulose and lignin are separated by physical and chemical methods, and the separated hemicellulose is in the liquid phase, that is, the hemicellulose liquid;

[0081] The hemicellulose liquid enters the wastewater treatment system and undergoes the pretreatment stage, biochemical treatment stage and advanced treatment stage successively. The pretreatment stage removes suspended solids to produce primary sludge, and the biochemical treatment stage removes a large amount of soluble COD to produce residual activated sludge. The treatment stage removes a small amount of pollutants that are not easily biodegradable to produce chemical sludge;

[0082] Primary sludge, residual activated sludge and chemical sludge are mixed, concentrated, flocculated, dehydrated, ventilated in the particle workshop, and dried to avoid direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com