Superhigh temperature-resistant adhesive based on liquid polycarbosilane ceramic precursor and preparation method thereof

A technology of ceramic precursor and polycarbosilane, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor bonding performance, material corrosion, poor thermal shock resistance, etc., and achieve good heat dissipation. Stability, high shear strength, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The liquid polycarbosilane ceramic precursor of the present invention can be synthesized according to the preparation method of the novel liquid polycarbosilane disclosed in the publication number CN104177621A, and the title of the invention is "a new type of liquid polycarbosilane and its preparation method and application", specifically May include the following steps:

[0028] (1) Add magnesium chips or magnesium powder to a dry ether solvent, and drop a small amount of chloromethylalkoxysilane or chloromethylalkoxysilane and chloromethyldimethoxysilane, methyl chloride methoxysilane and ether solvent, after the reaction is initiated, add chloromethylalkoxysilane or chloromethylalkoxysilane and chloromethyldimethoxysilane, chloromethyl-methoxysilane dropwise under stirring Mixed solution of base silane and ether solvent, react at 0~80℃ for 1~12h;

[0029] (2) Add dropwise Grignard reagents containing reactive groups or halogenated hydrocarbons or chloromethylsilane ...

Embodiment 1

[0039] Embodiment 1, preparation and application of adhesive

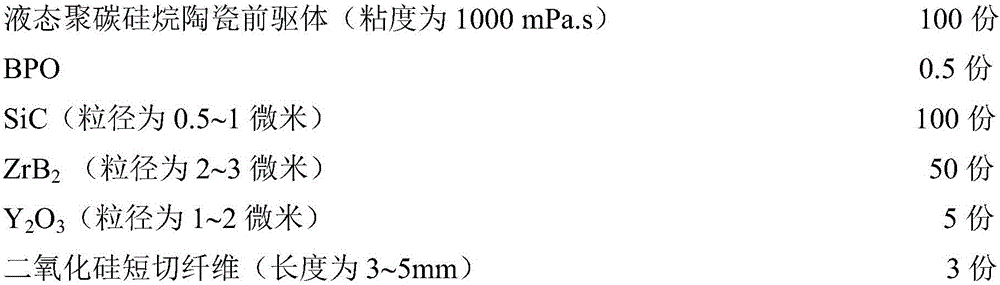

[0040] 1. Formula

[0041] In parts by weight, the adhesive of this embodiment consists of the following components:

[0042]

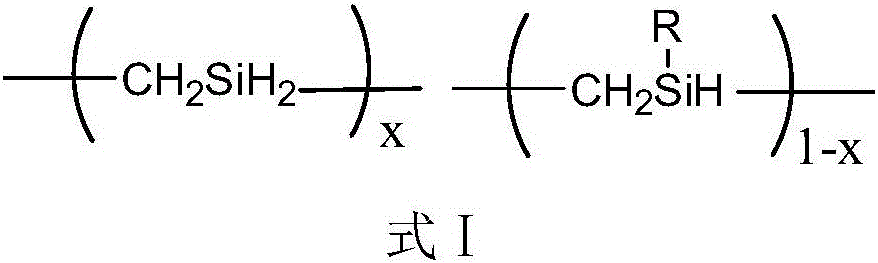

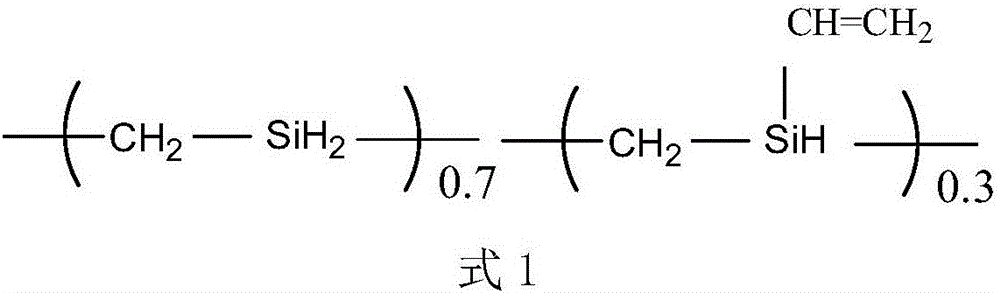

[0043] Wherein, the liquid polycarbosilane ceramic precursor includes two structural units in the following molar ratio:

[0044]

[0045] 2. Preparation method

[0046] (1) Preparation of liquid polycarbosilane ceramic precursor shown in formula 1

[0047] Prepare the liquid polycarbosilane ceramic precursor shown in Formula 1 as follows:

[0048] A dry 1L three-necked round-bottomed flask is connected with a mechanical stirrer, a reflux condenser, a constant pressure dropping funnel and a gas guiding device, and then evacuated to replace nitrogen three times, while baking with a heat gun to remove attached water vapor. Under a nitrogen atmosphere, add 5.0 g of magnesium chips into the reaction flask, then add 4 mL of tetrahydrofuran, and heat to 30°C. A mixed solution of 2.97 ...

Embodiment 2

[0059] Embodiment 2, preparation and application of adhesive

[0060] 1. Formula

[0061] In parts by weight, the adhesive of this embodiment consists of the following components:

[0062]

[0063]

[0064] Wherein, the liquid polycarbosilane ceramic precursor includes two structural units in the following molar ratio:

[0065]

[0066] 2. Preparation method

[0067] (1) Preparation of liquid polycarbosilane ceramic precursor shown in formula 2

[0068] Prepare the liquid polycarbosilane ceramic precursor shown in Formula 2 as follows:

[0069] A dry 1L three-necked round-bottomed flask is connected with a mechanical stirrer, a reflux condenser, a constant pressure dropping funnel and a gas guiding device, and then evacuated to replace nitrogen three times, while baking with a heat gun to remove attached water vapor. Under a nitrogen atmosphere, add 5.0 g of magnesium chips into the reaction flask, then add 4 mL of tetrahydrofuran, and heat to 30°C. A mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com