Sn-Bi base brazing filler metal used for producing crystal silicon heterojunction solar cell electrode

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high battery cost, avoid massive consumption, improve power generation efficiency, and reduce inherent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

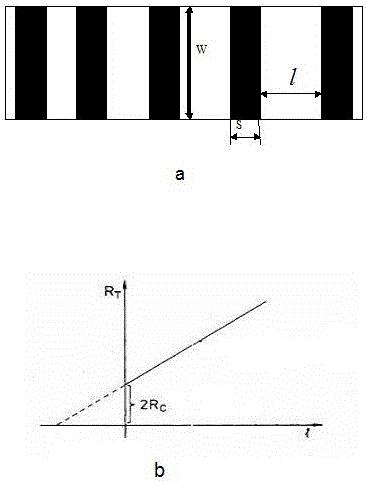

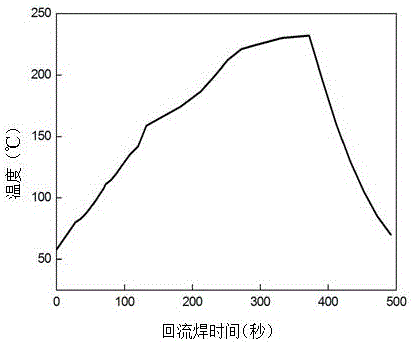

[0016] Melt the Sn-15Bi alloy, cast it at 250°C into a round rod with a diameter of 20mm, cut it into a short column with a height of 10mm, and grind the cross section to make it smooth. The volume resistance was measured by the four-probe method. The volume resistivity of the alloy was measured to be 33 μΩ·cm. The paste made of alloy powder was screen-printed on ITO to form an attached figure 1 The grid line shown in a, wherein the length w of the grid line is 10mm, and the width s is 2mm. to attach figure 2 The temperature regime shown is reflow soldering to obtain metal grid wire electrodes. Measure the total resistance R between any two adjacent grid lines with a multimeter T . make R T ~l linear relationship diagram, as attached figure 1 As shown in b, the contact resistance between the electrode made of the alloy and ITO is 0.50Ω.

Embodiment 2

[0018] Melt the Sn-35Bi-0.5Sb alloy, cast it at 250°C into a round rod with a diameter of 20mm, cut it into a short column with a height of 10mm, and grind the cross section to make it smooth. The volume resistance was measured by the four-probe method. The volume resistivity of the alloy was measured to be 45 μΩ·cm. The paste made of alloy powder was screen-printed on ITO to form an attached figure 1 The grid line shown in a, wherein the length w of the grid line is 10mm, and the width s is 2mm. to attach figure 2 The temperature regime shown is reflow soldering to obtain metal grid wire electrodes. Measure the total resistance R between any two adjacent grid lines with a multimeter T . make R T ~l linear relationship diagram, as attached figure 1 As shown in b, the contact resistance between the electrode made of the alloy and ITO is 0.58Ω.

Embodiment 3

[0020] Melt the Sn-52Bi-0.3Al alloy, cast it at 250°C into a round rod with a diameter of 20mm, cut it into a short column with a height of 10mm, and grind the cross section to make it smooth. The volume resistance was measured by the four-probe method. The volume resistivity of the alloy was measured to be 58 μΩ·cm. The paste made of alloy powder was screen-printed on ITO to form an attached figure 1 The grid line shown in a, wherein the length w of the grid line is 10mm, and the width s is 2mm. to attach figure 2 The temperature regime shown is reflow soldering to obtain metal grid wire electrodes. Measure the total resistance R between any two adjacent grid lines with a multimeter T . make R T ~l linear relationship diagram, as attached figure 1 As shown in b, the contact resistance between the electrode made of the alloy and ITO is 0.65Ω.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com