Gas-liquid mass transfer box and bio-trickling filter

A biological trickling filter tower, gas-liquid mass transfer technology, applied in the direction of air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low packing utilization, poor mass transfer effect, and insufficient biological purification system treatment Capacity and other issues, to achieve the effect of strengthening the mass transfer effect and improving the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

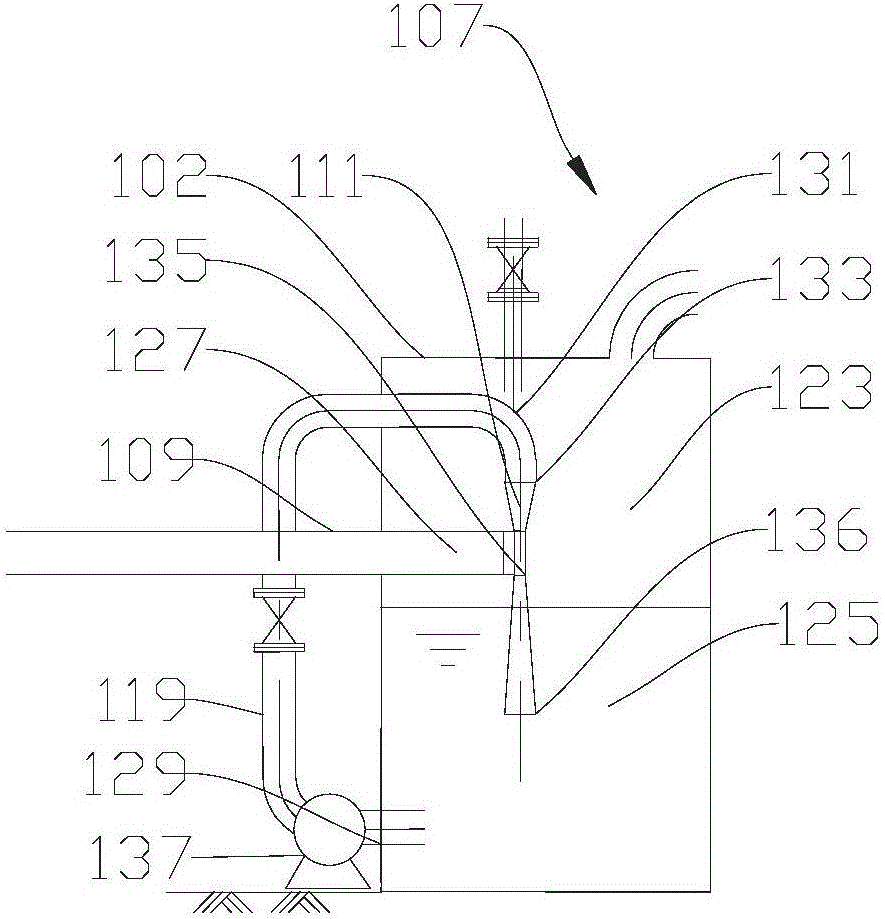

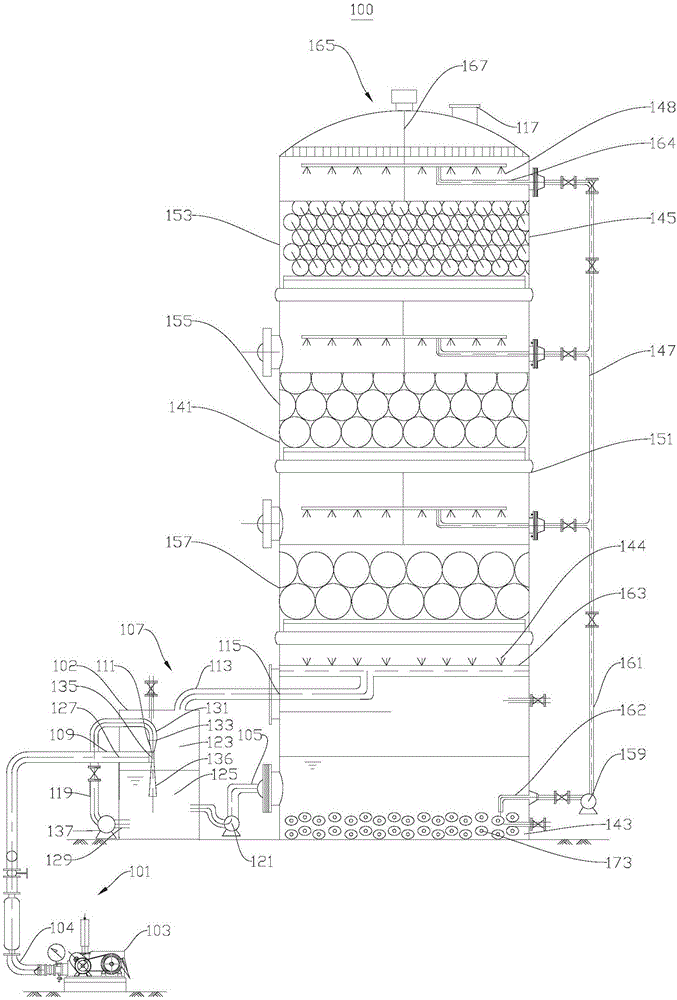

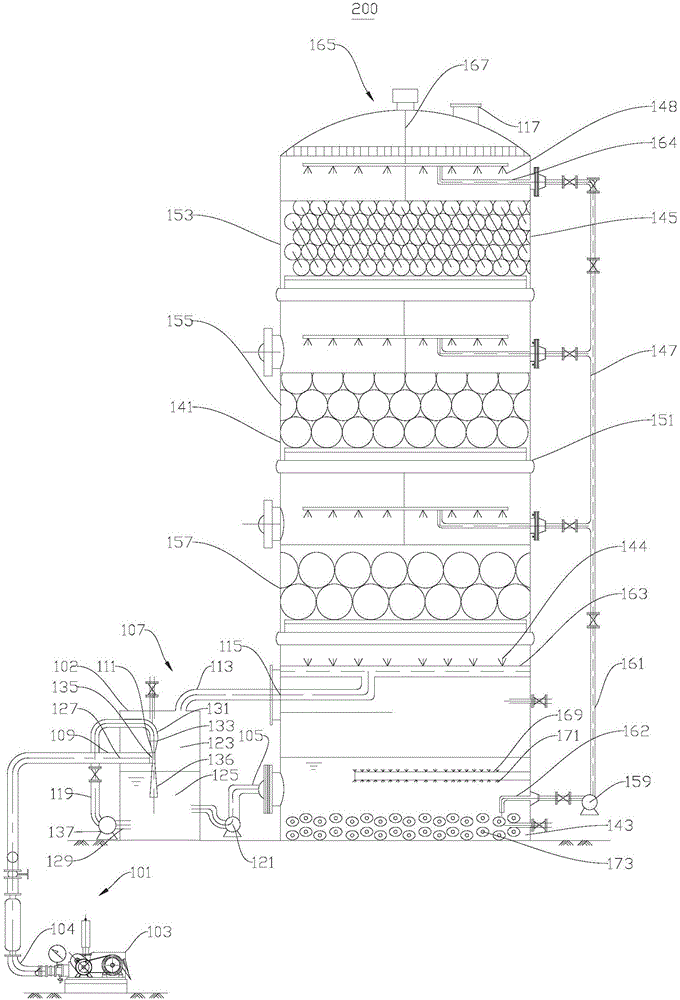

[0031] refer to figure 1 , this embodiment provides a gas-liquid mass transfer tank 107 , including: a tank body 102 , an inlet pipe 109 , a Venturi tube 111 , a liquid inlet pipe 119 , and a delivery pump 137 .

[0032] In this embodiment, the inside of the tank body 102 has a cavity for containing the working fluid, and the cavity is divided into a first space 123 and a second space 125 by the working fluid. The working liquid is placed in the second space 125 .

[0033]Among them, the working liquid can be various liquids used to treat exhaust gas, and further can be a mixed aqueous solution of non-ionic surfactant Tween 80 with nutrients added and solubilized. The added nutrients are available for microorganisms What is required for growth, the addition of surfactants can also increase the mutual solubility effect between gas and liquid, thereby also enhancing the gas-liquid mass transfer effect accordingly.

[0034] In this example, see figure 1 and figure 2 , the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com