A kind of flaky self-assembled basic copper carbonate curd and its simple preparation method

A self-assembly, copper carbonate technology, applied in chemical instruments and methods, copper compounds, inorganic chemistry, etc., to achieve the effect of narrow particle size distribution, easily controllable conditions, and difficult to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

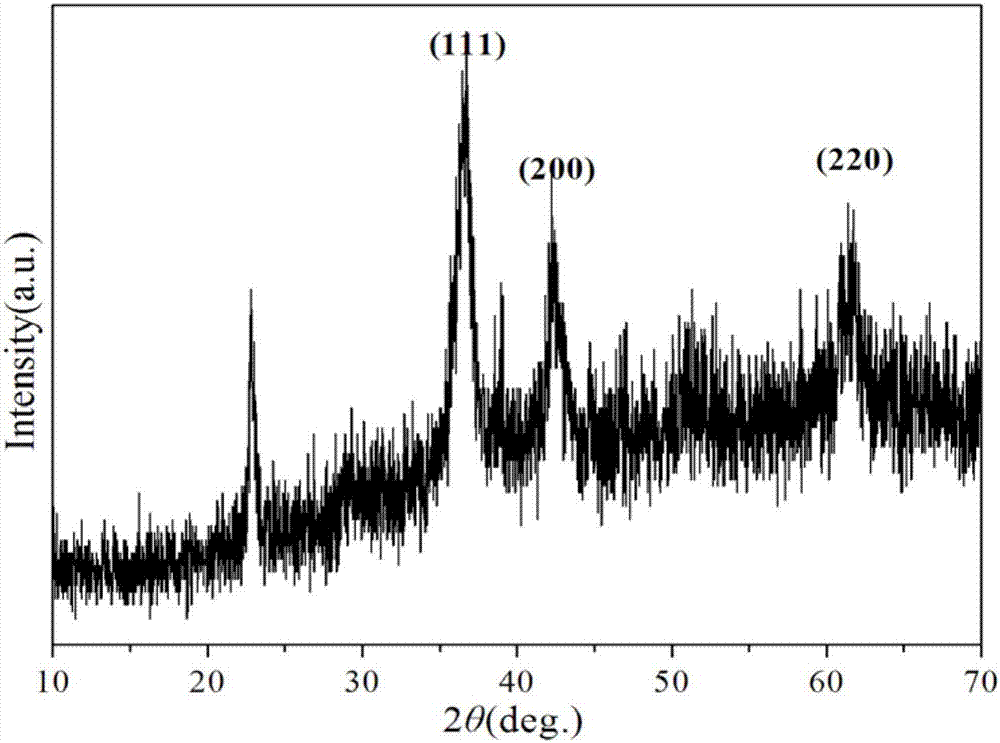

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

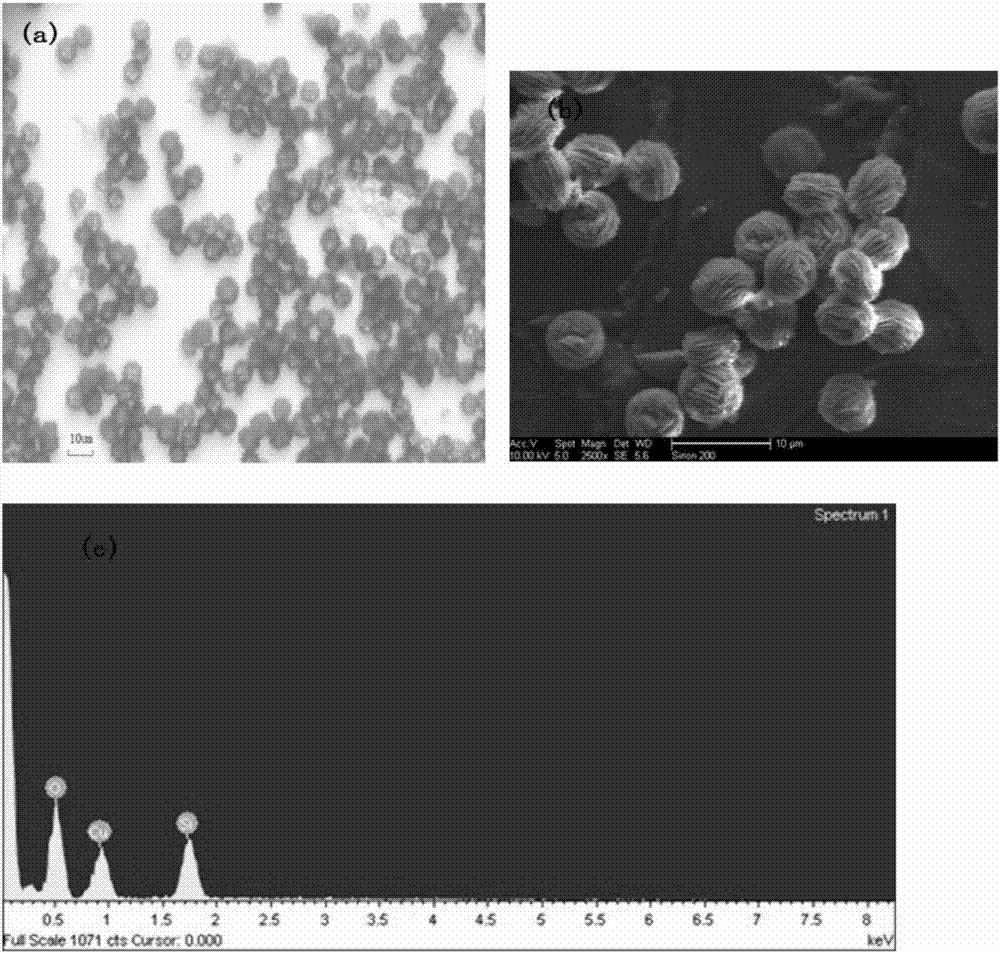

Embodiment 1

[0024] Preparation of sheet-like self-assembled basic copper carbonate curds:

[0025] (1) Weigh 1 mmol of L-aspartic acid into a beaker, add 10 mL of absolute ethanol and 5 mL of deionized water to dissolve, and stir on a magnetic stirrer for 30 min to form solution A. Weigh 4mmol Cu(NO 3 ) 2 ·3H 2 Pour O into a beaker, add 10 mL of deionized water to dissolve it, keep the same conditions, and stir for 30 min to form solution B. Add the stirred solution A to the solution B and place it in an ultrasonic cleaner for 30 minutes to form a solution C.

[0026] (2) Transfer solution C into the 50mL reaction kettle washed in advance, then rinse the beaker with 5mL deionized water and pour it into the reaction kettle; cover the reaction kettle and put it in a constant temperature blast drying oven, set the temperature to 120°C, react for 6h; after the reaction is over, take out the reaction kettle, centrifuge the powder generated after the reaction with a centrifuge, wash with ab...

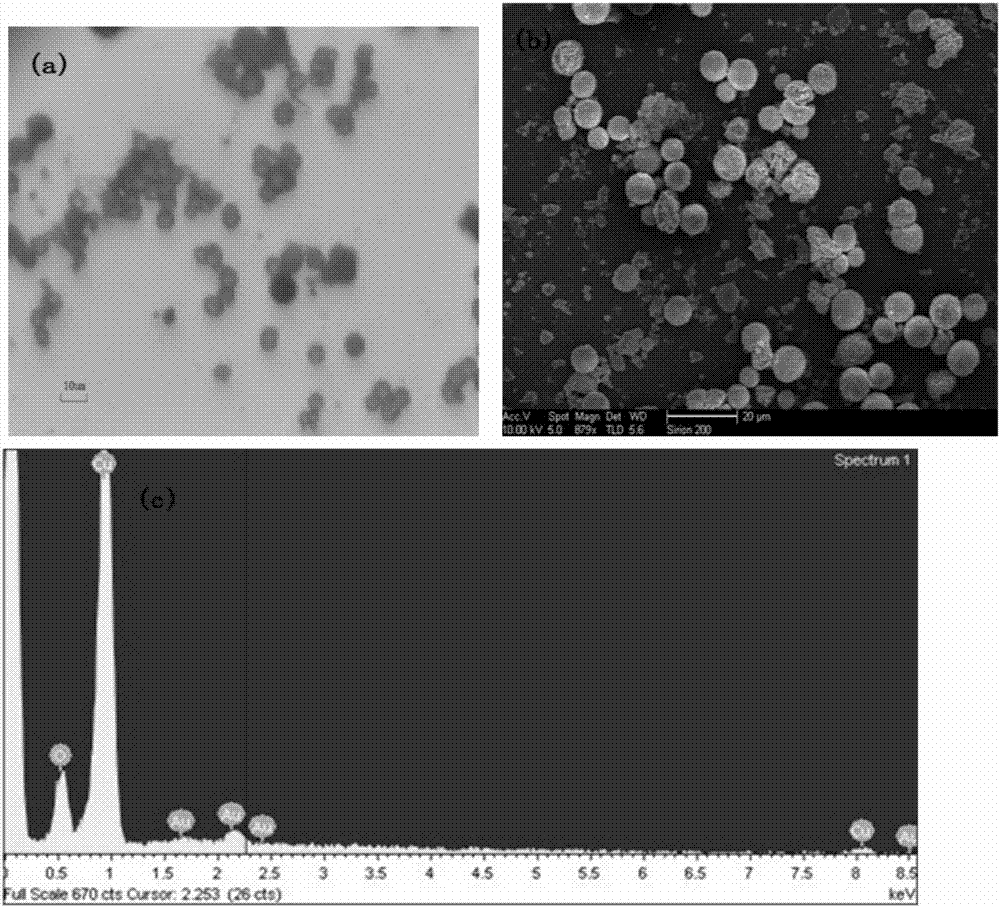

Embodiment 2

[0030] Preparation of sheet-like self-assembled basic copper carbonate curds:

[0031] (1) Weigh 2 mmol of L-aspartic acid into a beaker, add 10 mL of absolute ethanol and 5 mL of deionized water to dissolve, and stir on a magnetic stirrer for 30 min to form solution A. Weigh 1 mmol of copper acetate and pour it into a beaker, add 10 mL of deionized water to dissolve it, keep the same conditions, and stir for 30 min to form solution B. Add the stirred solution A to the solution B and place it in an ultrasonic cleaner for 30 minutes to form a solution C.

[0032] (2) Transfer solution C into the 50mL reaction kettle washed in advance, then rinse the beaker with 5mL deionized water and pour it into the reaction kettle; cover the reaction kettle and put it in a constant temperature blast drying oven, set the temperature to 140°C, react for 6h; after the reaction is over, take out the reaction kettle, centrifuge the powder generated after the reaction, wash with absolute ethanol ...

Embodiment 3

[0035] Preparation of sheet-like self-assembled basic copper carbonate curds:

[0036] (1) Weigh 1 mmol of L-aspartic acid into a beaker, add 5 mL of absolute ethanol and 10 mL of deionized water to dissolve, and stir on a magnetic stirrer for 30 min to form solution A. Weigh 1 mmol of copper chloride and pour it into a beaker, add 10 mL of deionized water to dissolve it, keep the same conditions, and stir for 30 min to form solution B. Add the stirred solution A to the solution B and place it in an ultrasonic cleaner for 30 minutes to form a solution C.

[0037] (2) Transfer solution C into the 50mL reaction kettle washed in advance, then rinse the beaker with 5mL deionized water and pour it into the reaction kettle; cover the reaction kettle and put it in a constant temperature blast drying oven, set the temperature to 160°C, react for 10h; after the reaction is over, take out the reactor, centrifuge the powder generated after the reaction, wash with absolute ethanol and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com