Lead-free compound ferroelectric ceramic composed of potassium-bismuth titanate and zinc oxide and preparation thereof

A technology of ferroelectric ceramics and composite ceramics, applied in the field of ferroelectric ceramics, can solve problems such as limiting the application range and temperature stability of KBT-based systems, and achieve the effects of improving various properties and inhibiting phase transitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

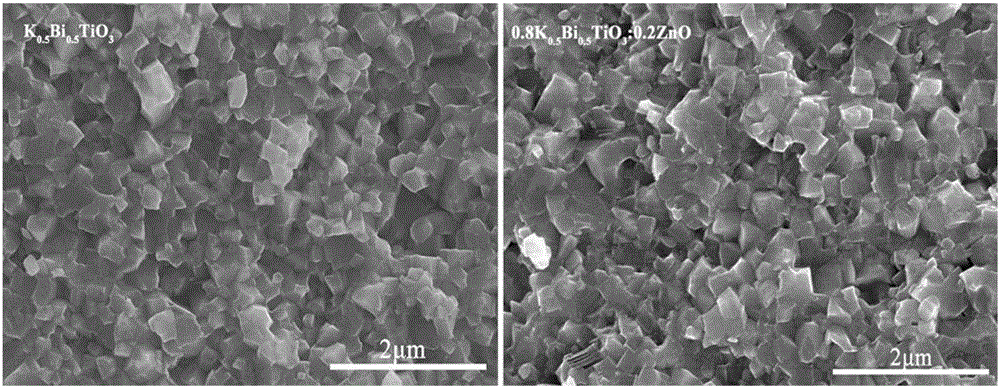

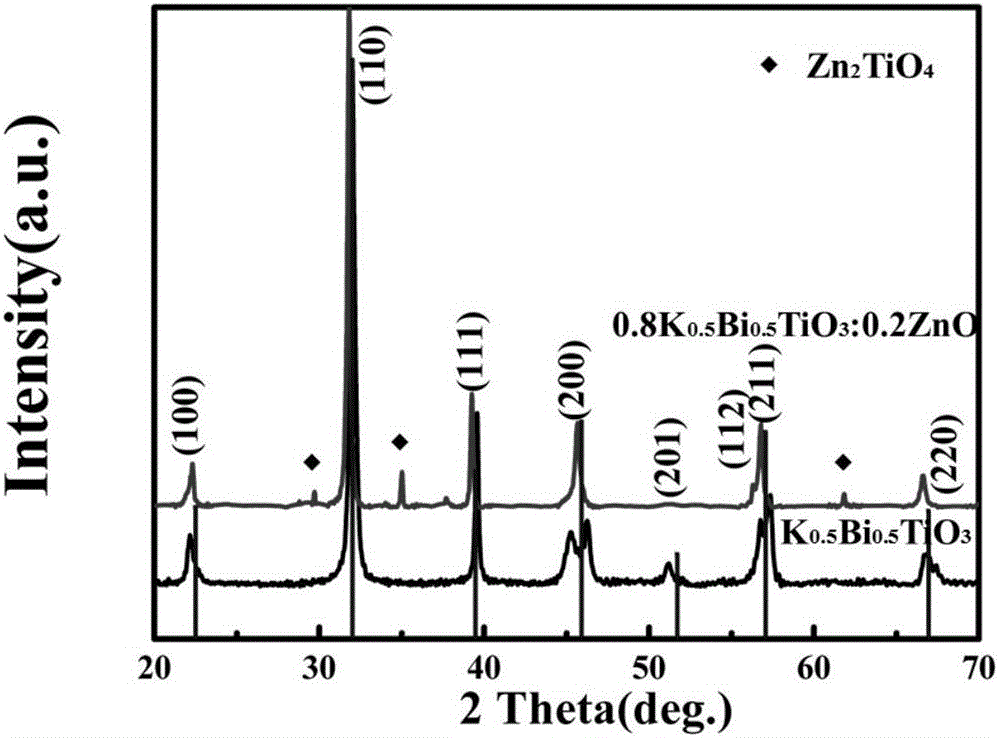

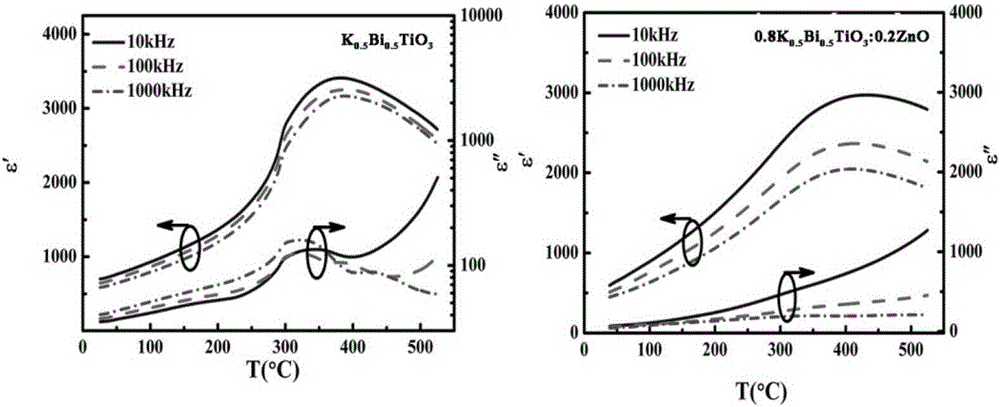

[0023] Recipe: 0.8K 0.5 Bi 0.5 TiO 3 :0.2ZnO

[0024] K 0.5 Bi 0.5 TiO 3 Preparation of powders for analytically pure K 2 CO 3 (99.99%), Na 2 CO 3 (99.99%) and Bi 2 o 3 (99.99%) as raw material, according to K 0.5 Bi 0.5 TiO 3 Weigh the raw materials according to the elemental ratio, ball mill them in absolute ethanol for 12 hours, dry them, calcinate them at 800°C for 2 hours, ball mill them again for 12 hours, and dry them to obtain the pure perovskite phase structure K 0.5 Bi 0.5 TiO 3 Powder. To improve K 0.5 Bi 0.5 TiO 3 phase stability, the K obtained by calcination 0.5 Bi 0.5 TiO 3 The powder was pre-sintered at 980°C for 2 hours, ball milled for 12 hours, and dried for K 0.5 Bi 0.5 TiO 3 : Preparation of ZnO composite ceramics.

[0025] 0.8K 0.5 Bi 0.5 TiO 3 : Preparation of 0.2ZnO composite ceramic sample Weigh the K obtained by pre-sintering in molar ratio 0.5 Bi 0.5 TiO 3 Powder and ZnO nanopowder (particle size about 30nm), ball mill...

Embodiment 2

[0027] Recipe: 0.75K 0.5 Bi 0.5 TiO 3 :0.25ZnO

[0028] K 0.5 Bi 0.5 TiO 3 The powder calcining temperature is 840°C, hold for 4 hours, the pre-calcination temperature is 1010°C, hold for 3 hours, K 0.5 Bi 0.5 TiO 3 : The sintering temperature of ZnO multiphase ceramics is 1030°C, and the temperature is kept for 2h. Others are with embodiment 1.

Embodiment 3

[0030] Recipe: 0.75K 0.5 Bi 0.5 TiO 3 :0.25ZnO

[0031] K 0.5 Bi 0.5 TiO 3 The powder calcining temperature is 820°C, hold for 3 hours, the pre-calcination temperature is 1000°C, hold for 2.5h, K 0.5 Bi 0.5 TiO 3 : The sintering temperature of ZnO multiphase ceramics is 1020°C, and the temperature is kept for 2.5h. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com