Method for preparing epoxide by halogen-alcohol method

An epoxide and hydroxide technology, applied in the direction of organic chemistry, etc., can solve the problems of intractability, environmental pollution, and high COD in wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

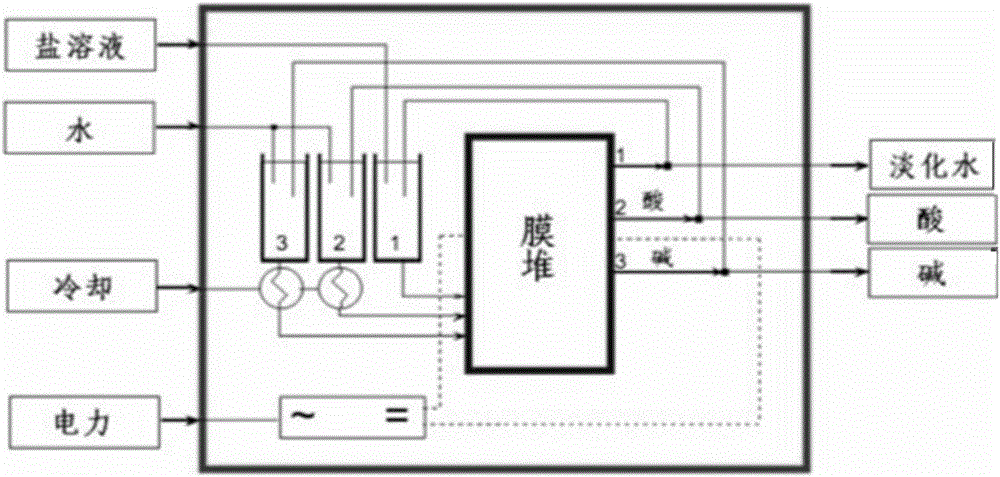

[0080] A method for preparing epoxides by haloalcohol method, the method may further comprise the steps:

[0081] (1) Haloalcoholization: add water (H 2 O), chlorine, ethylene, and carry out haloalcoholation reaction to obtain chloroethanol; add a catalyst, the catalyst is tungstic acid; the weight ratio of ethylene to the catalyst is 1:0.3.

[0082] (2) saponification: carry out saponification reaction with the chloroethanol of step (1) and sodium hydroxide, separate and obtain oxirane and sodium chloride;

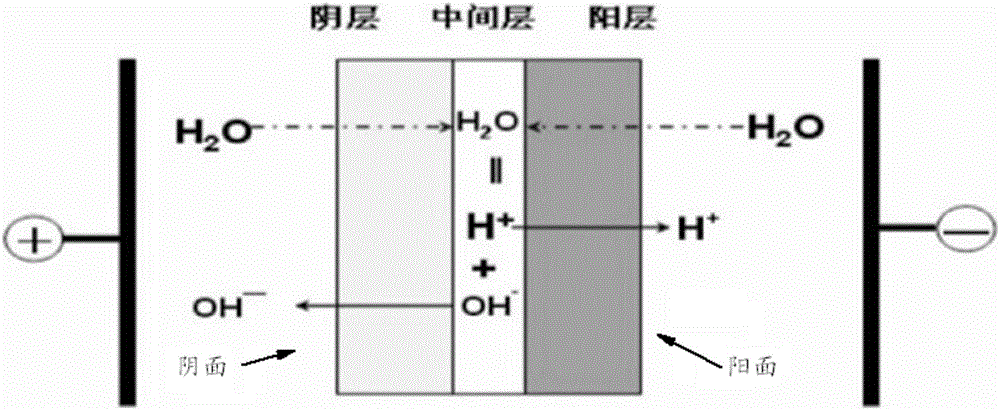

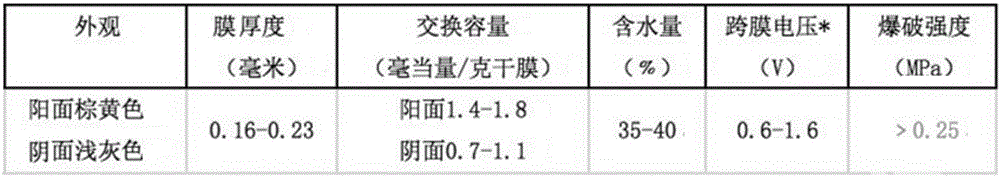

[0083] (3) Electrodialysis: the sodium chloride obtained in step (2) is subjected to bipolar membrane electrodialysis to obtain sodium hydroxide and hydrogen chloride.

[0084] Wherein: the molar ratio of ethylene to chlorine in step (1) is 1:1.5; the molar ratio of ethylene to water is 1:2; the reaction temperature in step (1) is 30°C. The molar ratio of chloroethanol and sodium hydroxide in the step (2) is 1:3; the reaction temperature in the step (2) is 45°C. The re...

Embodiment 2

[0092] A method for preparing epoxides by haloalcohol method, the method may further comprise the steps:

[0093] (1) Halogenation: add H in the reaction device 2 O, chlorine, ethylene, carry out haloalcoholization reaction to obtain chloroethanol; add catalyst, the catalyst is HTS-1 molecular sieve; the weight ratio of ethylene to catalyst is 1:0.5.

[0094] (2) saponification: carry out saponification reaction with the chloroethanol of step (1) and sodium hydroxide, separate and obtain oxirane and sodium halide chloride;

[0095] (3) Electrodialysis: the sodium chloride obtained in step (2) is subjected to bipolar membrane electrodialysis to obtain sodium hydroxide and hydrogen chloride.

[0096] (4) Refining of epoxide, step (2) obtains oxirane to obtain refined oxirane through rectification.

[0097]Wherein: the molar ratio of ethylene and chlorine in step (1) is 1:2; the molar ratio of ethylene and water is 1:5; the reaction temperature in step (1) is 40°C. The molar r...

Embodiment 3

[0099] Repeat embodiment 2, just add the acid binding agent in step (1); The acid binding agent is calcium carbonate. The molar ratio of ethylene to calcium carbonate is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com