a plastic adhesive

A technology of adhesives and plastics, applied in the direction of adhesives, asphalt material adhesives, adhesive types, etc., can solve problems such as poor adhesion, achieve the effects of reducing organic harmful substances, low cost, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

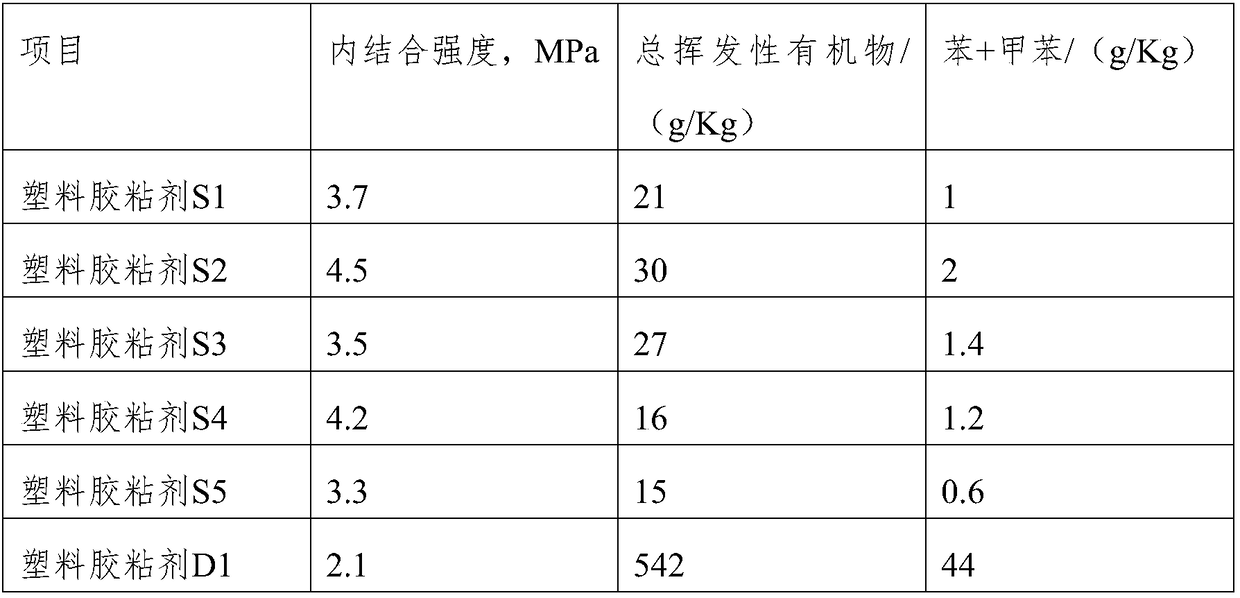

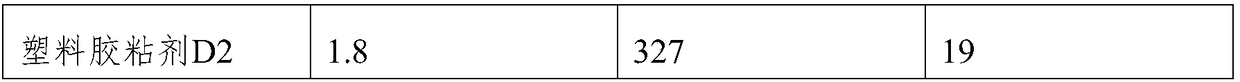

Examples

Embodiment 1

[0035] Put 1,000 grams of asphalt and 15 liters of n-heptane into an industrial 30-liter reactor, heat up to 130°C, and treat at this temperature for 8 hours. The obtained product is filtered on an industrial filter cloth to obtain brown of the filtrate.

[0036] All the filtrates were introduced into a liquid dryer, and then dried at 120° C. for 5 hours by feeding 50 liters / hour of nitrogen gas to obtain a black blocky solid.

[0037] The massive solid was pulverized in a pulverizer and then put into a pulverizer for pulverization treatment. The treatment time was 12 minutes to obtain black particles.

[0038] After passing the black particles through a 100-mesh sieve, take 300 grams and 2000 grams of ethyl α-cyanoacrylate, 30 grams of urethane diol, 30 grams of 2,4,4-trimethyl-1,6-hexane Diamine, 30 grams of ethylene carbonate, 30 grams of dichlorohexamethylene diisocyanate, 30 grams of melamine formaldehyde resin, 30 grams of E-44 epoxy resin, 30 grams of vinyl chloride re...

Embodiment 2

[0040] Put 1,000 grams of asphalt and 8 liters of n-heptane into an industrial 30-liter reaction kettle, heat up to 100°C, and treat at this temperature for 10 hours. The obtained product is filtered on an industrial filter cloth to obtain brown of the filtrate.

[0041] All the filtrates were introduced into a liquid dryer, and then dried at 120° C. for 5 hours by feeding 50 liters / hour of nitrogen gas to obtain a black blocky solid.

[0042] The massive solid was pulverized in a pulverizer and then put into a pulverizer for pulverization treatment. The treatment time was 12 minutes to obtain black particles.

[0043] After passing the black particles through a 100-mesh sieve, take 300 grams and 1500 grams of ethyl α-cyanoacrylate, 30 grams of urethane diol, 30 grams of 2,4,4-trimethyl-1,6-hexane Diamine, 30 grams of ethylene carbonate, 30 grams of dichlorohexamethylene diisocyanate, 30 grams of melamine formaldehyde resin, 30 grams of E-44 epoxy resin, 30 grams of vinyl chl...

Embodiment 3

[0045] Put 1,000 grams of asphalt and 12 liters of n-heptane into an industrial 30-liter reaction kettle, heat up to 150°C, and treat at this temperature for 1 hour, and filter the obtained product on an industrial filter cloth to obtain brown of the filtrate.

[0046] All the filtrates were introduced into a liquid dryer, and then dried at 120° C. for 5 hours by feeding 50 liters / hour of nitrogen gas to obtain a black blocky solid.

[0047] The massive solid was pulverized in a pulverizer and then put into a pulverizer for pulverization treatment. The treatment time was 12 minutes to obtain black particles.

[0048] After passing the black particles through a 100-mesh sieve, take 300 grams and 4500 grams of ethyl α-cyanoacrylate, 30 grams of urethane diol, 30 grams of 2,4,4-trimethyl-1,6-hexane Diamine, 30 grams of ethylene carbonate, 30 grams of dichlorohexamethylene diisocyanate, 30 grams of melamine formaldehyde resin, 30 grams of E-44 epoxy resin, 30 grams of vinyl chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com