Scale remover used for long-acting pressure decrease and injection increase of water injection well

A descaling agent and technology for water injection wells, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as mismatch between acid liquid and scale samples, short effective period of measures, and poor descaling effect, etc., to reduce Water injection pressure, increase water injection volume, good anti-swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of above-mentioned descaling agent, concrete steps are as follows:

[0029] (1) To the dry enamel reaction kettle, add 12-14 parts of water, 25-30 parts of organic phosphonic acid carboxylic acid scale inhibitor, 5-8 parts of anionic surfactant, 10-12 parts of polyoxygen Ethylene sorbitan monooleate, 13-15 parts of polyamino polyether group methylene phosphoric acid, stirring;

[0030] (2) Add 3-6 parts of silicone surfactant while stirring until all solvents are completely mixed;

[0031] (3) Heat the reactor to 72°C to 78°C for 1 to 4 hours, then cool to room temperature;

[0032] (4) Add 15-18 parts of diluent and 2-5 parts of dispersant, discharge, and complete the preparation of descaling agent for long-term depressurization and injection increase of water injection wells.

[0033] The above medicament components are all commercially available chemicals.

[0034] The descaling agent for water injection wells synthesized by the invention fo...

Embodiment 1

[0036] This example provides a descaling agent for long-term decompression and increasing injection in water injection wells. The descaling agent is composed of the following components in parts by mass: 10 parts of polyoxyethylene sorbitan monooleate; 25 parts of organic phosphonic acid carboxylic acid scale inhibitor; 5 parts of anionic surfactant; 3 parts of silicone surfactant; 2 parts of dispersant; 15 parts of diluent; .

[0037] The preparation method of the above scale remover is to add 12 parts of water, 25 parts of organic phosphonic acid carboxylic acid scale inhibitors, 5 parts of anionic surfactants, 10 parts of polyoxyethylene sorrel into a dry enamel reaction kettle. Alcohol monooleate, 13 parts of polyaminopolyether-based methylene phosphoric acid, stirring; while stirring, add 3 parts of silicone surfactant until the various solvents are completely mixed; heat the reactor to 72 ° C for 1 hour , cooled to room temperature; 15 parts of diluent and 2 parts of di...

Embodiment 2

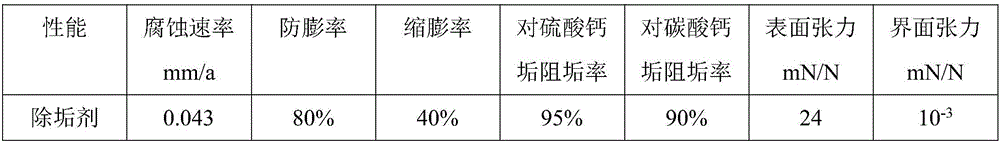

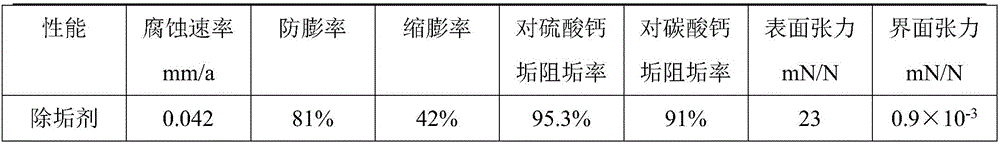

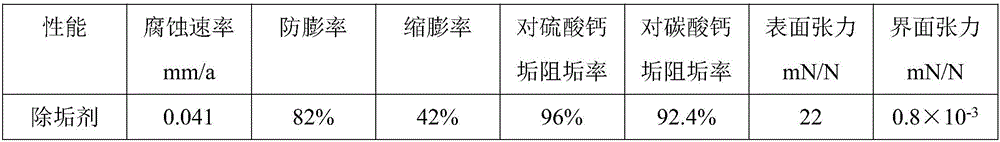

[0045] The present embodiment takes 11 parts of polyoxyethylene sorbitan monooleate; 26 parts of tricarboxylic butanephosphonic acid; 6 parts of α-sulfomonocarboxylic acid; 4 parts of cyclic polysiloxane; triethylhexyl 3 parts of phosphoric acid; 16 parts of industrial ethanol; 14 parts of polyamino polyether methylene phosphoric acid; 13 parts of water, and make a descaling agent according to the above-mentioned preparation method, and inject the descaling agent with a concentration of 0.2% into multiple ports continuously for 1 week For under-injection wells, during the time period of injection, detect the corrosion rate of the scale remover provided in this embodiment to equipment and pipe strings, the anti-expansion rate, shrinkage rate, and resistance to calcium carbonate and calcium sulfate of the scale remover. The scale inhibition rate, as well as the surface tension and interfacial tension of this scale remover, the performance and effect of specific testing are shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com