Brass alloy with macro-hole, micron-hole and nano-hole hierarchical hole structure and application thereof

A brass alloy and nanopore technology, applied in the field of brass alloy preparation, can solve the problems of lack of mechanical integrity of the sample, single antibacterial bacteria, long production cycle, etc., to reduce the complexity of equipment, simple components, antibacterial effect Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step is to prepare the macropores of the brass alloy

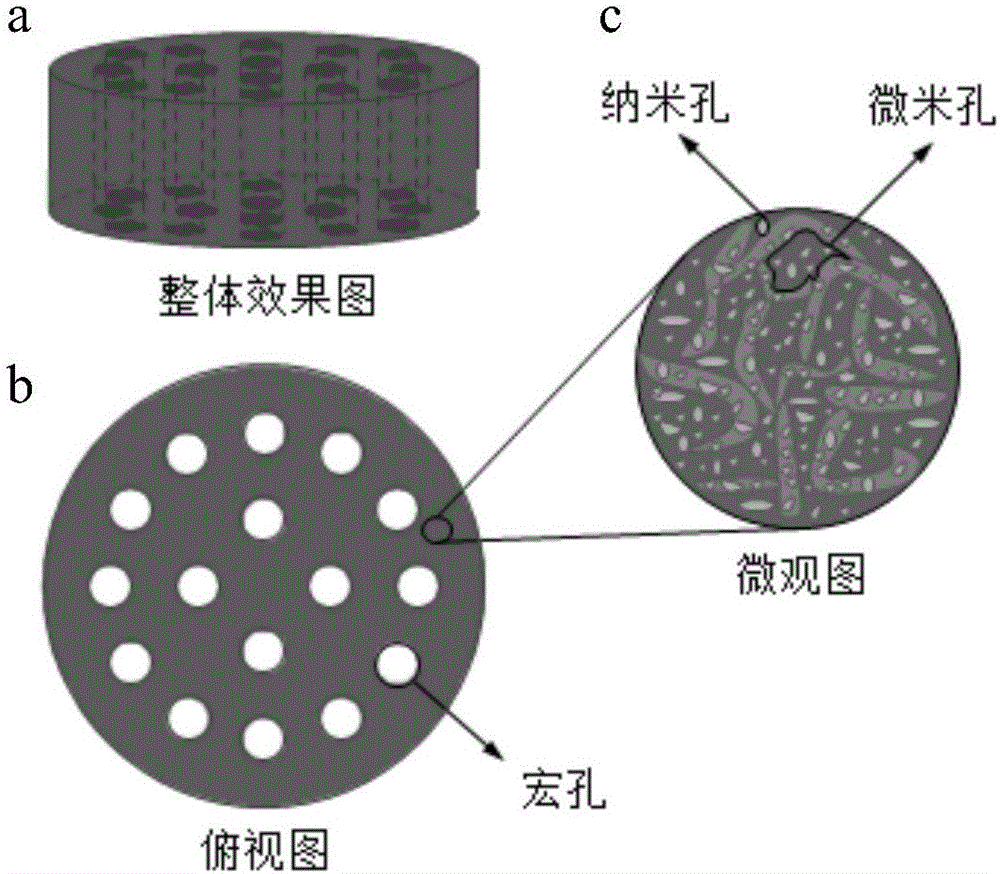

[0033] Utilize numerical control machining technology to process the Cu-41wt.%Zn (impurityfigure 1 a shows the overall effect after processing, figure 1 b shows a schematic diagram of the distribution of macropores, with a total of 16 pores. The prepared samples were washed successively with acetone, absolute ethanol and ultrapure water, and then placed in a vacuum drying oven and dried at 60°C for 2 hours.

[0034] The second step, preparation of micro-nanopores in brass alloys

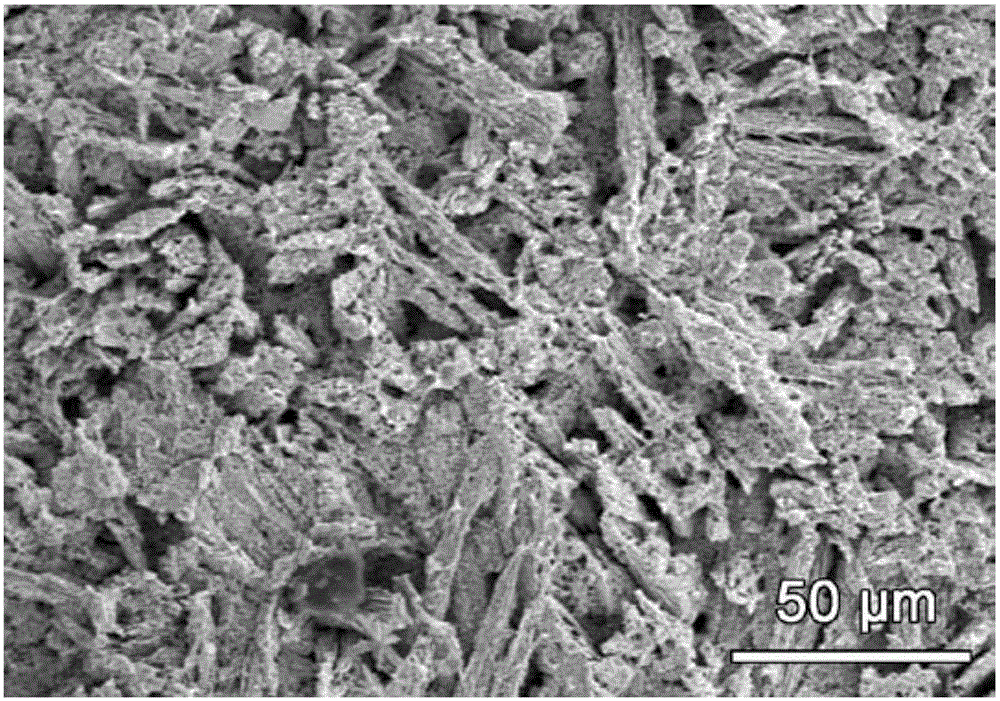

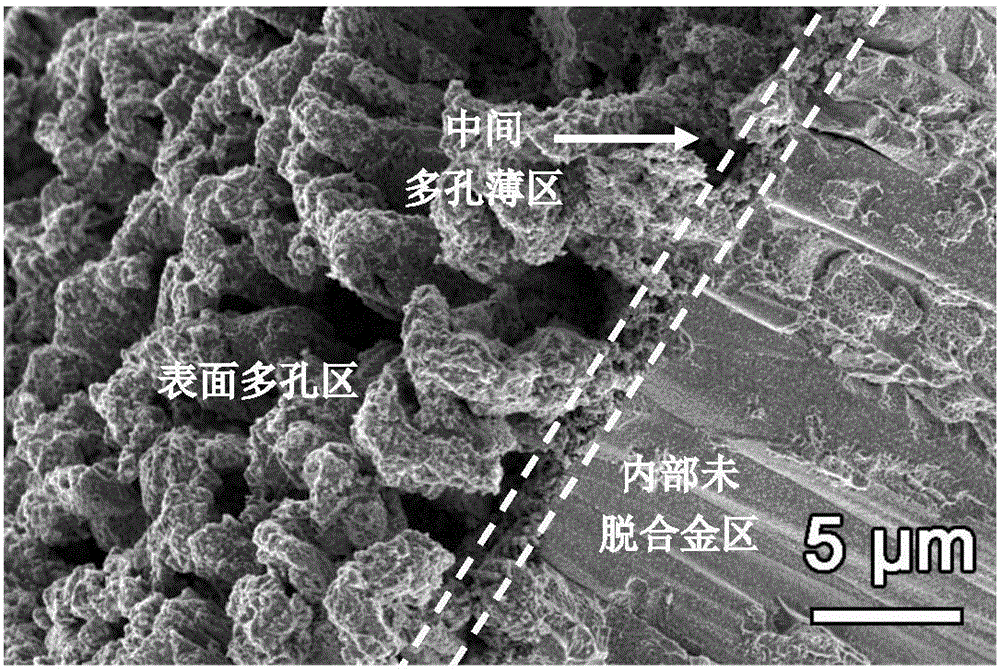

[0035] The porous brass cylinder with macropore array prepared in the first step was immersed in a nitric acid solution with a mass concentration of 5% for dealloying treatment. This process was carried out at 37°C, and the dealloying time was controlled at 20 minutes. After dealloying, the brass cylinder forms a multi-level pore structure with macropores-micropores-nanopores, such as figure 1 b and figure 1 c shows the schem...

Embodiment 2

[0040] The first step is to prepare the macropores of the brass alloy

[0041] Utilize numerical control machining technology to process the Cu-39wt.%Zn (impurity Figure 6 A schematic diagram showing the distribution of macropores is shown, with a total of 52 pores. The prepared samples were washed successively with acetone, absolute ethanol and ultrapure water, and then placed in a vacuum drying oven and dried at 60°C for 2 hours.

[0042] The second step, preparation of micro-nanopores in brass alloys

[0043] The porous brass cylinder with a macropore array prepared in the first step was immersed in a nitric acid solution with a mass concentration of 4.5% for dealloying treatment. This process was carried out at 35°C, and the dealloying time was controlled at 10 minutes. After dealloying, the brass cylinders form a hierarchical porous structure with macropores-micropores-nanopores. The prepared brass alloy was washed successively with 0.1M sodium hydroxide solution, alcoh...

Embodiment 3

[0047] The first step is to prepare the macropores of the brass alloy

[0048] Utilize numerical control processing technology to process the Cu-40wt.%Zn (impurity Figure 8 A schematic diagram showing the distribution of macropores is shown, with a total of 16 pores. The prepared samples were washed successively with acetone, absolute ethanol and ultrapure water, and then placed in a vacuum drying oven and dried at 60°C for 2 hours.

[0049] The second step, preparation of micro-nanopores in brass alloys

[0050] The porous brass cylinder with macropore array prepared in the first step was immersed in a nitric acid solution with a mass concentration of 6.5% for dealloying treatment. This process was carried out at 40°C, and the dealloying time was controlled at 30 minutes. After dealloying, the brass cylinders form a hierarchical porous structure with macropores-micropores-nanopores. The prepared brass alloy was washed successively with 0.1M sodium hydroxide solution, alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com