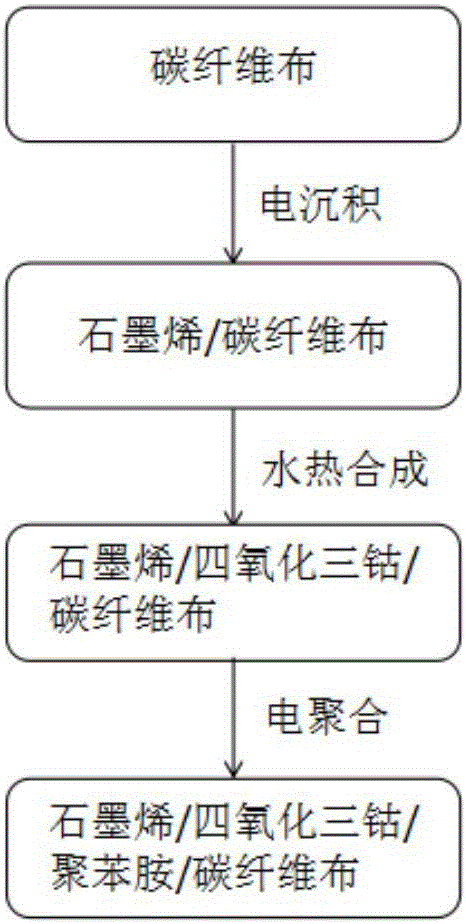

Preparation method of quaternary carbon fiber cloth/graphene/tricobalt tetraoxide/polyaniline composite electrode material

A technology of cobalt tetroxide and carbon fiber cloth, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of low energy density, poor electrical conductivity, limited specific capacitance, etc. Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of quaternary carbon fiber cloth / graphene / cobalt tetroxide / polyaniline composite electrode material, comprising the following steps:

[0034] Step 1. Take the carbon fiber cloth and ultrasonically clean it in absolute ethanol for 20 minutes, then rinse it with deionized water for 3 times, and then put it in a vacuum drying oven to dry at 60°C for 8 hours for later use;

[0035] Step 2. Take 1 mg / mL graphene oxide dispersion as the electrochemical deposition solution. In the three-electrode electrochemical workstation system, use carbon fiber cloth as the substrate (working electrode), Pt sheet as the counter electrode, and Ag / AgCl electrode As a reference electrode, by cyclic voltammetry, react for 10 cycles at a voltage range of -1.4-0.6V, and deposit graphene oxide on carbon fiber cloth to obtain a carbon fiber cloth / graphene composite;

[0036] Step three, the CoCl 2 , ammonium fluoride, urea and water are formulated into a uniform solution in t...

Embodiment 2

[0040] A preparation method of quaternary carbon fiber cloth / graphene / cobalt tetroxide / polyaniline composite electrode material, comprising the following steps:

[0041] Step 1. Take the carbon fiber cloth and ultrasonically clean it in absolute ethanol for 20 minutes, then rinse it with deionized water for 3 times, and then put it in a vacuum drying oven to dry at 60°C for 8 hours for later use;

[0042] Step 2. Take 3 mg / mL graphene oxide dispersion as the electrochemical deposition solution. In the three-electrode electrochemical workstation system, use carbon fiber cloth as the substrate (working electrode), Pt sheet as the counter electrode, and Ag / AgCl electrode As a reference electrode, by cyclic voltammetry, react for 9 cycles in the voltage range of -1.4-0.6V, deposit graphene oxide on carbon fiber cloth, and obtain carbon fiber cloth / graphene composite;

[0043] Step three, the CoCl 2 , ammonium fluoride, urea and water are formulated into a uniform solution in the ...

Embodiment 3

[0047] A preparation method of quaternary carbon fiber cloth / graphene / cobalt tetroxide / polyaniline composite electrode material, comprising the following steps:

[0048] Step 1. Take the carbon fiber cloth and ultrasonically clean it in absolute ethanol for 20 minutes, then rinse it with deionized water for 3 times, and then put it in a vacuum drying oven to dry at 60°C for 8 hours for later use;

[0049] Step 2. Take 5 mg / mL graphene oxide dispersion as the electrochemical deposition solution. In the three-electrode electrochemical workstation system, the carbon fiber cloth is used as the substrate (working electrode), the Pt sheet is used as the counter electrode, and the Ag / AgCl electrode is As a reference electrode, by cyclic voltammetry, 8 cycles were reacted at a voltage range of -1.4-0.6V, and graphene oxide was deposited on carbon fiber cloth to obtain a carbon fiber cloth / graphene composite;

[0050] Step three, the CoCl 2 , ammonium fluoride, urea and water are form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com