Porous membrane for flow battery and with hierarchical pore structure, and preparation and application thereof

A technology of liquid flow battery and all-vanadium redox flow battery, which is applied in the field of porous membranes, can solve the problems of difficult balance between selectivity and proton conductivity, achieve the controllability of battery efficiency and capacity, facilitate mass production, and improve selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

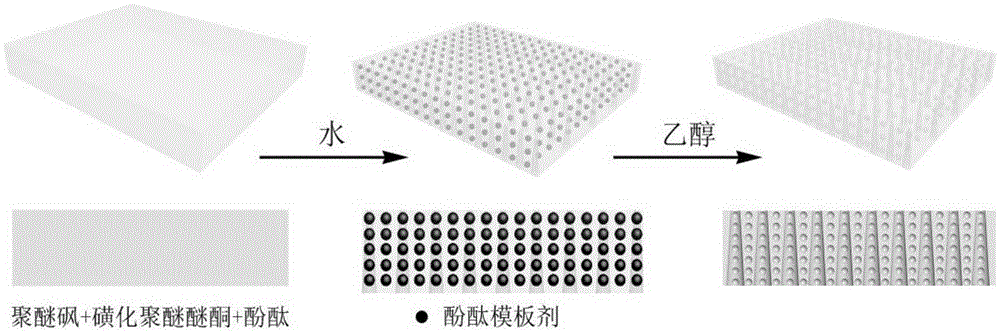

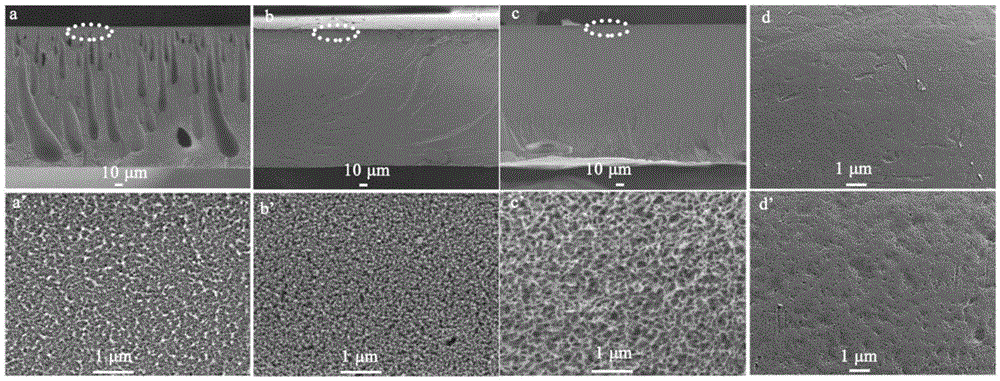

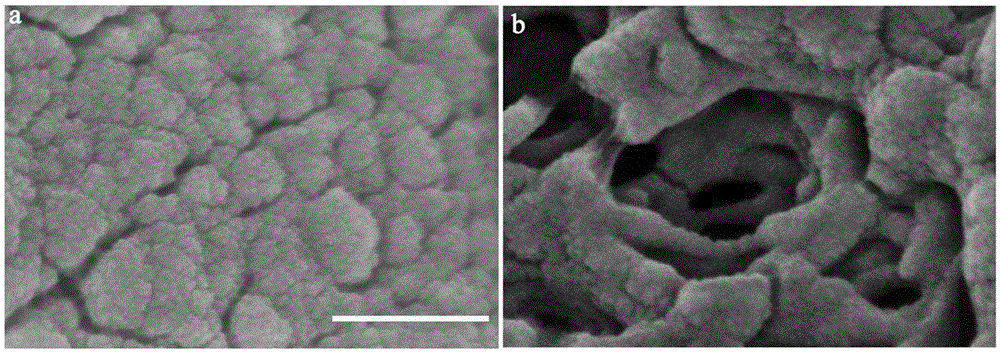

Embodiment 1

[0036] Dissolve 9.975g of polyethersulfone, 0.525g of sulfonated polyetheretherketone and 1.0506g of phenolphthalein in 19.5g of DMAC, stir for 48 hours, spread the polymer solution on a glass plate, and then quickly immerse it in 4L of water to solidify , forming a porous separator with a film thickness of 175 μm. Soak the prepared porous membrane in ethanol for 48 hours to remove the phenolphthalein template agent in the membrane, and prepare a porous membrane with hierarchical pore structure. Then wash with water and continue soaking in ethanol to completely remove the template agent in the film. The pore size of the porous membrane is 0.1 μm-0.2 μm, and the small pore size is 0.1-100 nm. The all-vanadium redox flow battery is assembled by using the prepared porous membrane with hierarchical pore structure, in which the catalytic layer is activated carbon felt, the bipolar plate is graphite plate, and the effective area of the membrane is 9cm 2 , the current density is ...

Embodiment 2

[0038] Dissolve 9.975g of polyethersulfone, 0.525g of sulfonated polyetheretherketone and 2.1g of phenolphthalein in 19.5g of DMAC, stir for 48 hours, spread the polymer solution on a glass plate, then quickly immerse in 4L of water, and solidify , forming a porous separator with a film thickness of 175 μm. Soak the prepared porous membrane in ethanol for 48 hours to remove the phenolphthalein template agent in the membrane, and prepare a porous membrane with hierarchical pore structure. Then wash with water and continue soaking in ethanol to completely remove the template agent in the film. The all-vanadium redox flow battery is assembled by using the prepared porous membrane with hierarchical pore structure, in which the catalytic layer is activated carbon felt, the bipolar plate is graphite plate, and the effective area of the membrane is 9cm 2 , the current density is 80mA.cm -2 , the vanadium ion concentration in the electrolyte is 1.50mol L -1 , H 2 SO 4 The conce...

Embodiment 3

[0041] Dissolve 9.975g of polyethersulfone, 0.525g of sulfonated polyetheretherketone and 3.15g of phenolphthalein in 19.5g of DMAC, stir for 48 hours, and spread the formed polymer solution on a glass plate, then quickly immerse in 4L of water, and solidify , forming a porous separator with a film thickness of 175 μm. Soak the prepared porous membrane in ethanol for 48 hours to remove the phenolphthalein template agent in the membrane, and prepare a porous membrane with hierarchical pore structure. Then wash with water and continue soaking in ethanol to completely remove the template agent in the film. The all-vanadium redox flow battery is assembled by using the prepared porous membrane with hierarchical pore structure, in which the catalytic layer is activated carbon felt, the bipolar plate is graphite plate, and the effective area of the membrane is 9cm 2 , the current density is 80mA.cm -2 , the vanadium ion concentration in the electrolyte is 1.50mol L -1 , H 2 SO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com