Nanometer multifunctional composite paint

A composite coating, multi-functional technology, applied in radiation-absorbing coatings, reflective/signal coatings, coatings, etc., can solve the problems of reduced appearance size, harsh curing conditions, and high production costs of photosensitive inks, reducing production costs and speeding up. The effect of promotion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0043]

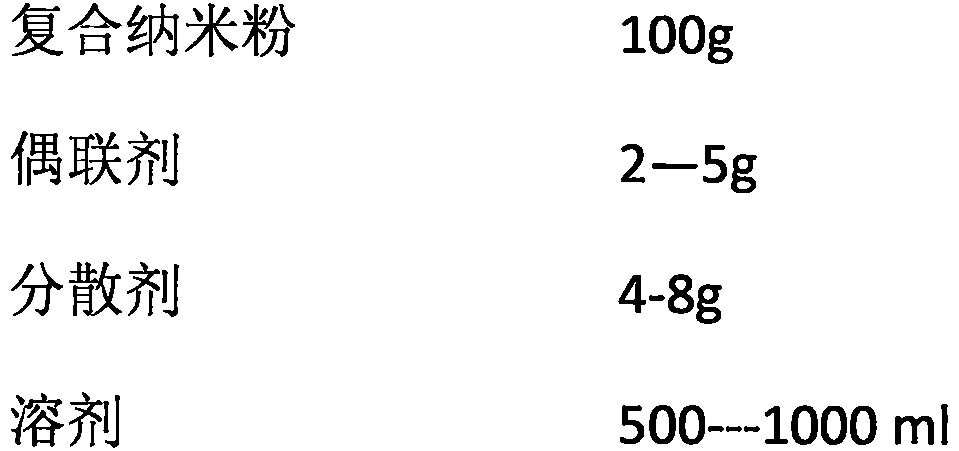

[0044] Measure 800ml of distilled water, add 3g of silane coupling agent KH550 into the distilled water, disperse the silane coupling agent KH550 evenly in the distilled water through a high-speed mixer, control the speed of the mixer between 1000-1500 rpm, and stir for 10 minutes; After the stirring is completed, add 5g of polyethylene glycol and stir again to completely dissolve the polyethylene glycol, and then stir the above mixture evenly with a high-speed mixer. The speed of the mixer is controlled between 1000-1500 rpm, and the stirring time is 8 Minutes, after the above steps are completed, add 100g of nano-zinc oxide, and use a high-speed mixer to disperse the nano-zinc oxide evenly in the above mixed solution. The speed of the mixer is controlled between 2000-2500 rpm, and the stirring time is 20 minutes; the above steps The preliminary mixing of nano-zinc oxide, distilled water, silane coupling agent KH550, and polyethylene glycol is completed. After the pr...

preparation example 2

[0046]

[0047] Measure 800ml of ethanol, add 4g of silane coupling agent KH570 into the ethanol, disperse the silane coupling agent KH570 evenly in the ethanol through a high-speed mixer, control the speed of the mixer between 2000-2500 rpm, and stir for 10 minutes; After the stirring is completed, add 5g of polyethylene glycol, and stir again to completely dissolve the polyethylene glycol, and then use a high-speed mixer to stir the above mixture evenly. The speed of the mixer is controlled between 2000-2500 rpm, and the stirring time is 8 Minutes, after the above steps are completed, add 100g of nano-magnesia and 70g of high-purity graphite powder, and use a high-speed mixer to disperse the nano-magnesia evenly in the above mixed solution. The speed of the mixer is controlled between 2000-2500 rpm. The time is 20 minutes; the above steps have completed the preliminary mixing of nano-magnesia, high-purity graphite powder, ethanol, silane coupling agent KH570, and polyethyl...

preparation example 3

[0049]

[0050] Measure 800ml of distilled water, add 4g of silane coupling agent KH570 into the distilled water, disperse the silane coupling agent KH570 evenly in the distilled water through a high-speed mixer, control the speed of the mixer between 2000-2500 rpm, and stir for 10 minutes; After the stirring is completed, add 5g of polyethylene glycol, and stir again to completely dissolve the polyethylene glycol, and then use a high-speed mixer to stir the above mixture evenly. The speed of the mixer is controlled between 2000-2500 rpm, and the stirring time is 8 After the above steps are completed, add 40g nano-magnesium oxide and 60g nano-zinc oxide, and use a high-speed mixer to disperse the nano-magnesia and nano-zinc oxide evenly in the above mixed solution. The speed of the mixer is controlled at 2000-2500 rpm The stirring time is 20 minutes; the above steps have completed the initial mixing of nano-magnesium oxide, nano-zinc oxide, distilled water, silane coupling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| UV absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com