A kind of adsorbent for purifying volatile organic waste gas and its preparation method

A volatile organic and adsorbent technology, applied in the field of new adsorbent-modified sepiolite-based molecular sieve and its preparation, can solve the problems of poor formability, low strength, easy cracking of the surface, etc., and achieve good adsorption effect and adsorption capacity High, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

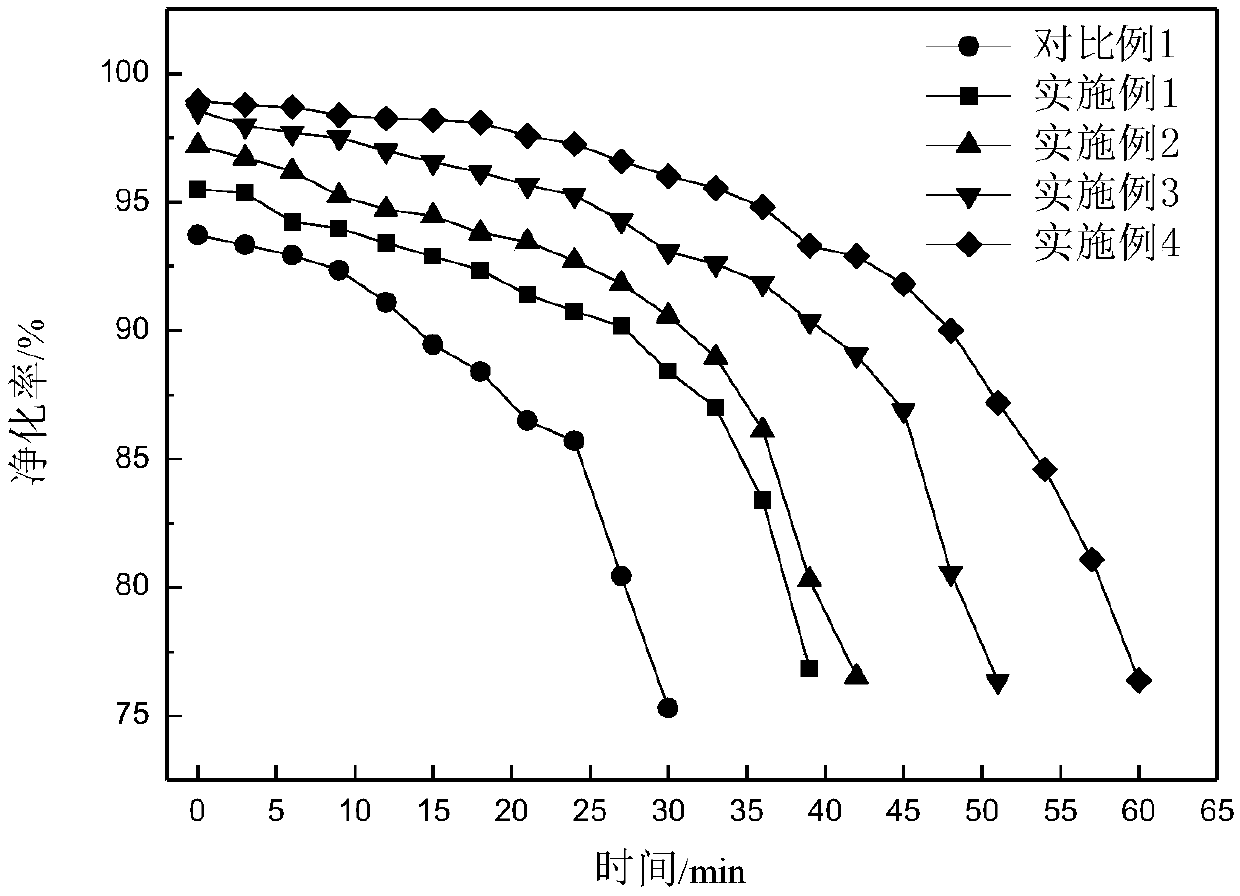

Embodiment 1

[0034] Grind the fibrous α-sepiolite into a powder with a particle size of 325 mesh through a roller mill, put the obtained sepiolite powder into a reaction kettle, add hydrochloric acid with a concentration of 0.2 mol / L, and the mixture of hydrochloric acid and sepiolite powder The liquid-solid ratio was 10 (L / kg), stirred at room temperature for 8 h, filtered, washed, and dried to obtain hydrochloric acid-activated sepiolite.

[0035] In the sepiolite activated by hydrochloric acid, add the aluminum dihydrogen phosphate solution with a mass fraction of 80%, and the silica sol with a mass fraction of 30% and mix evenly. The active ingredient accounts for 100 parts by weight. In the mixture, the aluminum dihydrogen phosphate accounts for 2 parts by weight, silica sol solid matter accounts for 3 parts by weight, polyvinyl butyral accounts for 2 parts by weight, and KH560 accounts for 2 parts by weight. After the mixture was placed in a closed container for 24 hours, it was pres...

Embodiment 2

[0038] Grind the fibrous α-sepiolite into a powder with a particle size of 325 mesh through a roller mill, put the obtained sepiolite powder into a reaction kettle, add hydrochloric acid with a concentration of 0.2 mol / L, and the mixture of hydrochloric acid and sepiolite powder The liquid-solid ratio was 10 (L / kg), stirred at room temperature for 8 h, filtered, washed, and dried to obtain hydrochloric acid-activated sepiolite.

[0039]Add 15% active carbon powder into the hydrochloric acid activated sepiolite, the particle size of the activated carbon powder is 325 mesh, to obtain the mixed raw material.

[0040] In the sepiolite activated by hydrochloric acid, add the aluminum dihydrogen phosphate solution with a mass fraction of 80%, and the silica sol with a mass fraction of 30% and mix evenly. The active ingredient accounts for 100 parts by weight. In the mixture, the aluminum dihydrogen phosphate accounts for 2 parts by weight, silica sol solid matter accounts for 3 part...

Embodiment 3

[0042] The fibrous α-sepiolite was ground into a powder with a particle size of 325 meshes by a roller mill, and the obtained sepiolite powder was placed in a reaction kettle, and hydrochloric acid with a concentration of 0.2 mol / L was added, and the mixture of hydrochloric acid and sepiolite powder was The liquid-solid ratio was 10 (L / kg), stirred at room temperature for 8 hours, filtered, washed, and dried to obtain hydrochloric acid-activated sepiolite.

[0043] A mesoporous zeolite molecular sieve with a mass fraction of 15% was added to the hydrochloric acid-activated sepiolite, and the particle size of the zeolite was 325 mesh to obtain a mixed raw material.

[0044] Add the aluminum dihydrogen phosphate solution with a mass fraction of 80% and the silica sol with a mass fraction of 30% in the mixed raw material and mix evenly. The active ingredient accounts for 100 parts by weight, and the aluminum dihydrogen phosphate in the mixture accounts for 2 parts by weight. , th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com