Method for preparing activated carbon through self-activation method

A technology for the preparation of activated carbon and self-activation, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of high production cost, high equipment corrosion, and difficult recovery, so as to improve the preparation quality and production efficiency, and achieve good Application prospect, effect of reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, a certain amount of straw is selected, and the straw is fully crushed in a pulverizer to 60 meshes, and then the crushed straw is fully dried at an ambient temperature of 105° C. to obtain pretreated straw powder;

[0034] After the drying is completed, weigh 50 g of the above-mentioned pretreated straw powder that has been fully dried, and put it into a high-temperature furnace to prepare for activation treatment. In this embodiment, the temperature is raised to 950° C. temperature, the activated carbon intermediate product is obtained after activation for 3 hours;

[0035] The activated carbon intermediate product after the activation is cooled to below 100°C in a nitrogen atmosphere and then taken out to obtain a specific surface area of 1161m 2 / g of activated carbon products.

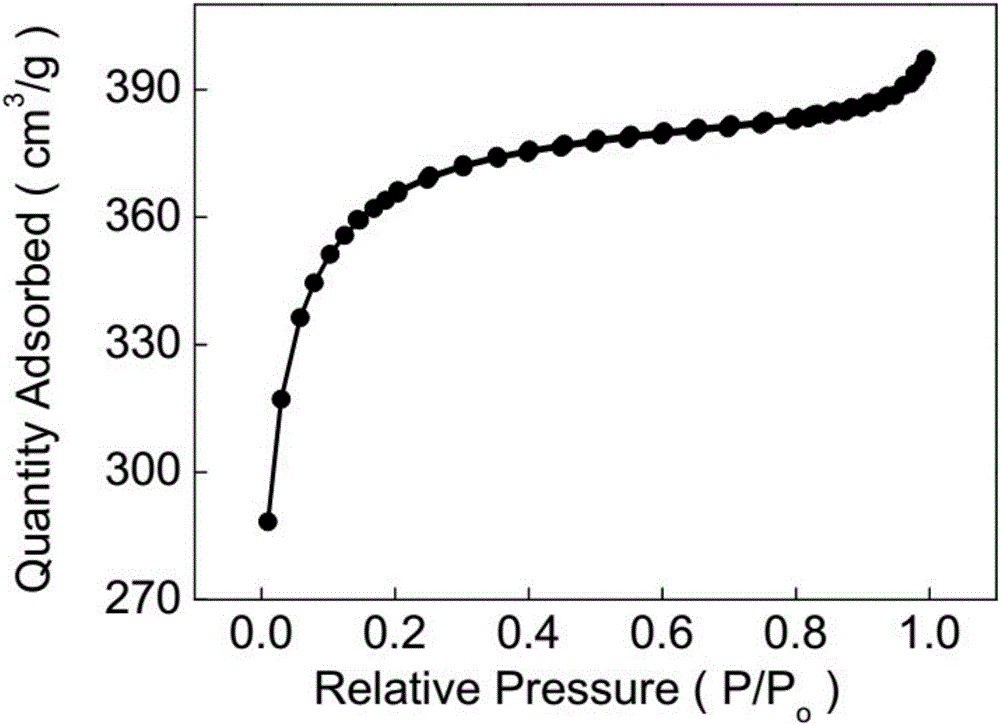

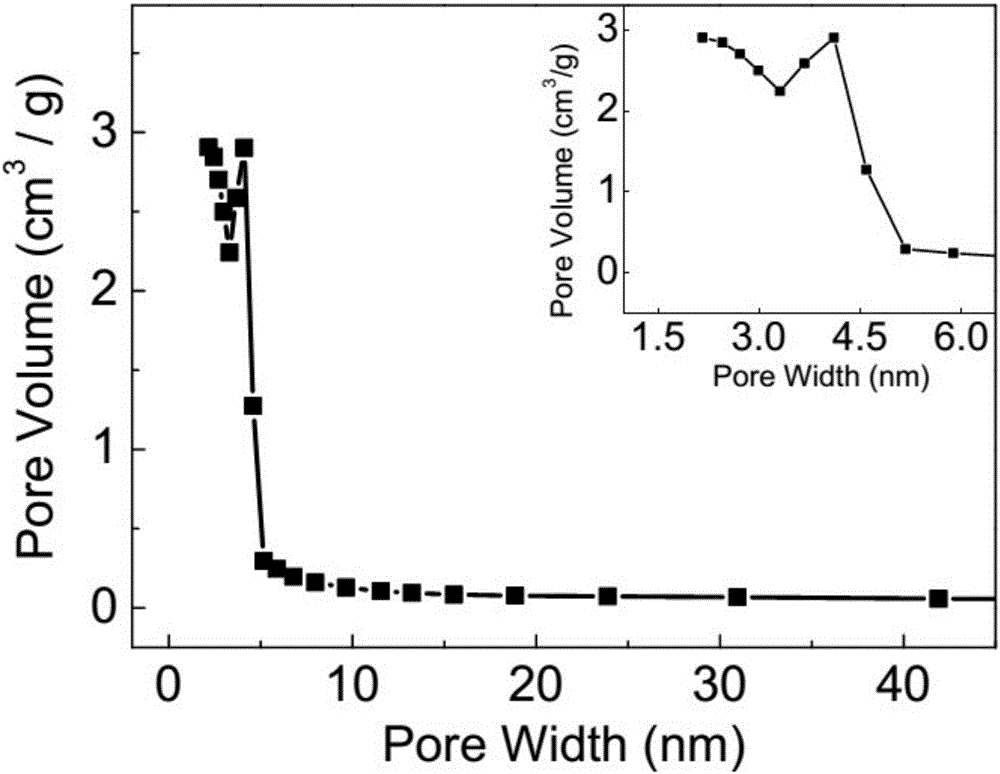

[0036] see figure 1 , figure 1 The nitrogen adsorption isotherm of activated carbon product in the method for the self-activation method that the first embodiment of the present ...

Embodiment 2

[0038] First, a certain amount of bagasse is selected, and the bagasse is fully pulverized in a pulverizer to 80 meshes, and then the pulverized bagasse is fully dried at an ambient temperature of 105° C. to obtain pretreated sugarcane powder;

[0039] After the drying is completed, weigh 50 g of the above-mentioned pretreated sugarcane powder that has been fully dried, and put it into a high-temperature furnace to prepare for activation treatment. In this embodiment, the temperature is raised to 900° C. temperature, the activated carbon intermediate product is obtained after activation for 4h;

[0040] The activated carbon intermediate product after activation is cooled to below 100°C in a nitrogen atmosphere and then taken out, with a specific surface area of 1259m 2 / g of activated carbon products.

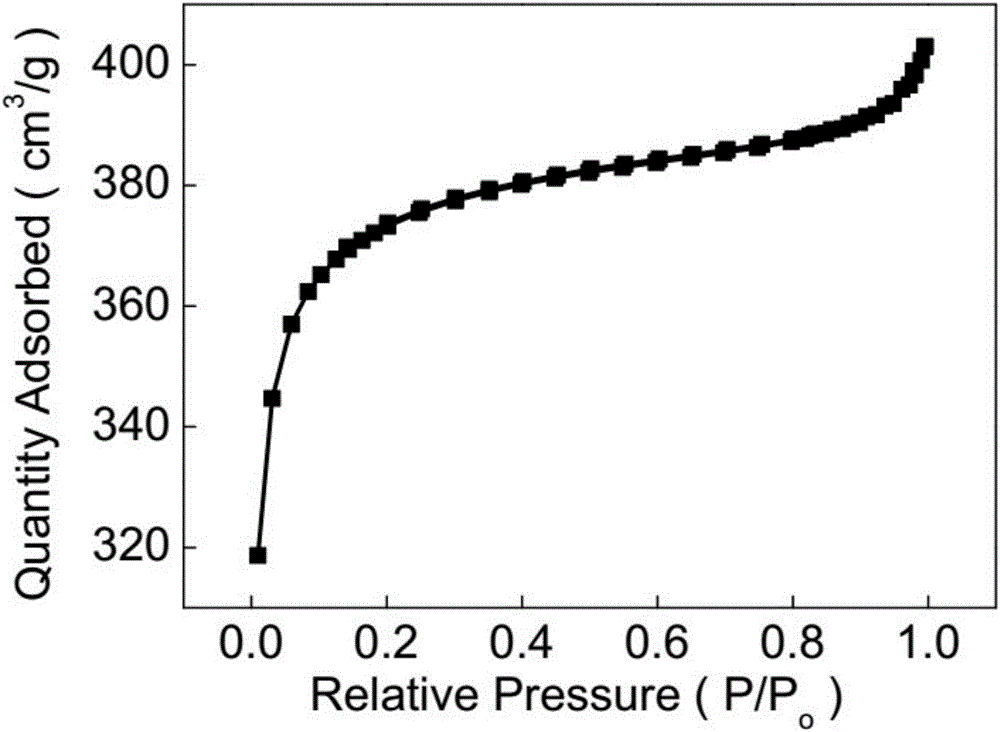

[0041] see image 3 , image 3The nitrogen adsorption isotherm of activated carbon product in the method for the self-activation method that the second embodiment of the p...

Embodiment 3

[0043] First, a certain amount of peanut shells are selected, and the peanut shells are fully crushed in a crusher to 100 meshes, and then the crushed bagasse is fully dried at an ambient temperature of 105° C. to obtain pretreated peanut shell powder;

[0044] After the drying is completed, weigh 50 g of the above-mentioned pretreated sugarcane powder that has been fully dried, and put it into a high-temperature furnace to prepare for activation treatment. In this embodiment, the temperature is raised to 1000° C. After 2.5 hours of activation, the intermediate product of activated carbon is obtained;

[0045] The activated carbon intermediate product after activation is cooled to below 100°C in a nitrogen atmosphere and then taken out, with a specific surface area of 1172m 2 / g of activated carbon products.

[0046] see Figure 5 , Figure 5 The nitrogen adsorption isotherm of activated carbon product in the method for the self-activation method that the third embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com