Ternary polymer degreasing agent used for thickened oil thermal production sewage treatment

A ternary polymer and heavy oil thermal recovery technology, applied in special compound water treatment, water/sewage treatment, mining wastewater treatment, etc., can solve problems such as corrosion, achieve less consumption, high oil removal efficiency, and source of raw materials wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Degreaser C 1 and its preparation method

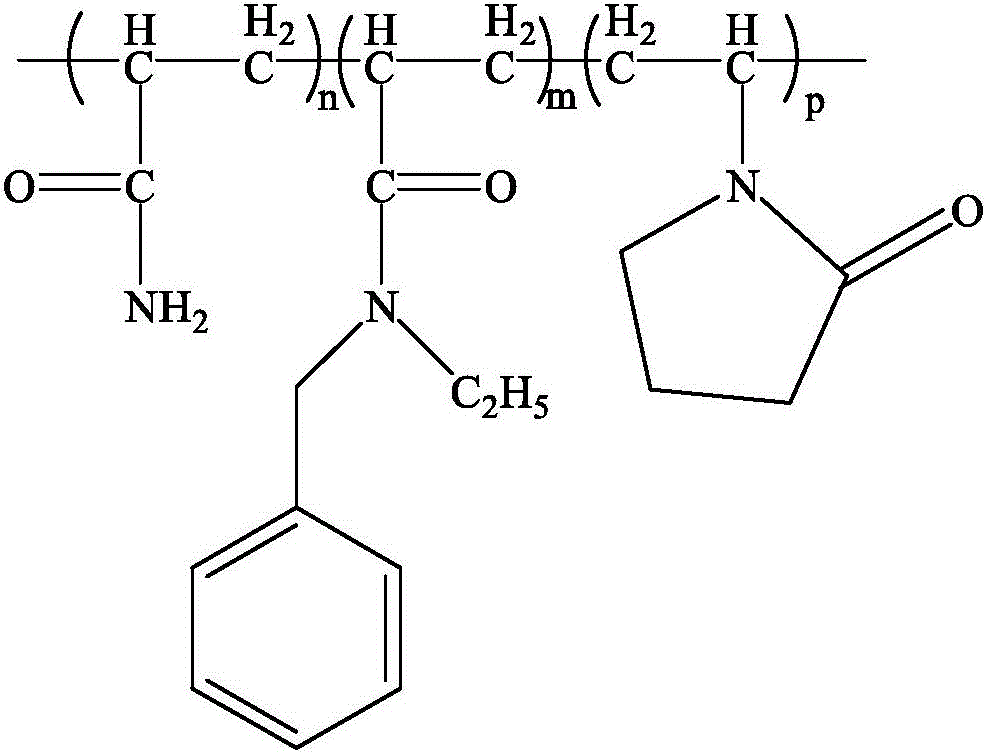

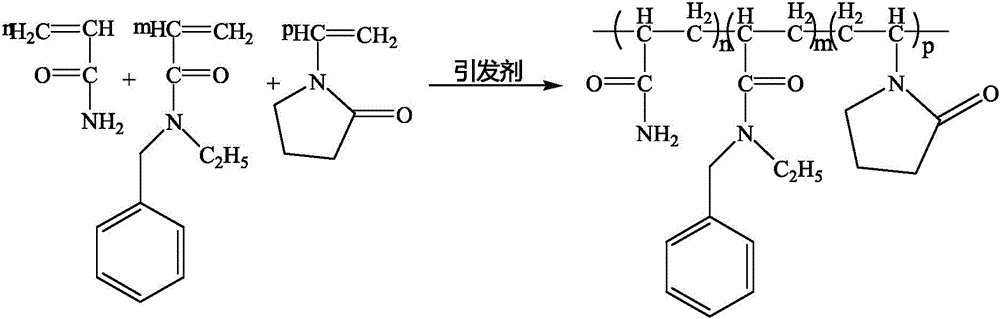

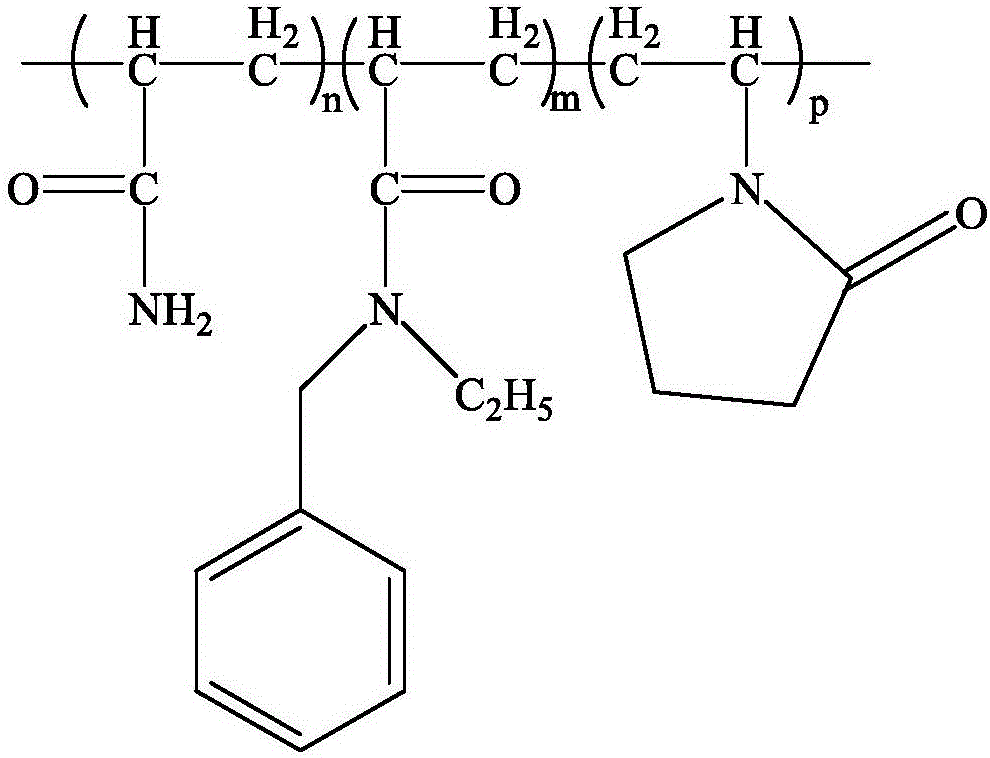

[0035] (1) Degreaser C 1 The composition, components and molecular weight are as follows:

[0036] Degreaser C 1 It is prepared from acrylamide, N-benzyl-N-ethylacrylamide and N-vinylpyrrolidone in a molar ratio of 1:1.1:1.5 by free radical micellar polymerization, with an average molecular weight of 42,000.

[0037] (2) Degreaser C 1 The preparation method is as follows:

[0038] ①Add 1052g of deionized water and 1.1mol of N-benzyl-N-ethylacrylamide into a three-necked flask equipped with a thermometer and a stirring rod, raise the temperature to 32°C at a stirring rate of 300rpm, and keep the temperature constant for 60min;

[0039] ② Add 1 mol of acrylamide to the above-mentioned three-necked flask, raise the temperature to 50°C, add 2.55g of sodium lauryl sulfate, stir for 30 minutes, and the stirring rate is 550rpm. After the stirring time is over, the temperature rises to 68°C. Constant temperature 50m...

example 2

[0042] Example 2: Degreaser C 2 and its preparation method

[0043] (1) Degreaser C 2 The composition, components and molecular weight are as follows:

[0044] Degreaser C 2 It is prepared from acrylamide, N-benzyl-N-ethylacrylamide and N-vinylpyrrolidone in a molar ratio of 1:0.1:0.5 through free radical micellar polymerization, with an average molecular weight of 12,000.

[0045] (2) Degreaser C 2 The preparation method is as follows:

[0046]①Add 710.8g of deionized water and 0.1mol of N-benzyl-N-ethylacrylamide into a three-necked flask equipped with a thermometer and a stirring rod, raise the temperature to 30°C at a stirring rate of 400rpm, and keep the temperature for 45min;

[0047] ② Add 1 mol of acrylamide to the above-mentioned three-necked flask, and raise the temperature to 45°C, add 1.42g of sodium dodecylsulfonate, stir for 25min at a stirring rate of 600rpm, after the stirring time ends, the temperature rises to 70°C , keep the temperature for 30min to ob...

Embodiment 3

[0050] Embodiment 3: Degreaser C 3 and its preparation method

[0051] (1) Degreaser C 3 The composition, components and molecular weight are as follows:

[0052] Degreaser C 3 It is prepared from acrylamide, N-benzyl-N-ethylacrylamide and N-vinylpyrrolidone in a molar ratio of 1:1.5:3 through free radical micellar polymerization, with an average molecular weight of 86,000.

[0053] (2) Degreaser C 3 The preparation method is as follows:

[0054] ①Add 1421.6g of deionized water and 1.5mol of N-benzyl-N-ethylacrylamide into a three-necked flask equipped with a thermometer and a stirring rod, raise the temperature to 35°C at a stirring rate of 500rpm, and keep the temperature for 30min;

[0055] ② Add 1 mol of acrylamide to the above-mentioned three-necked flask, raise the temperature to 40°C, add 3.55g of sodium lauryl sulfate, stir for 20 minutes, and the stirring speed is 500rpm. After the stirring time is over, the temperature rises to 65°C, Constant temperature 40min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com