Application of hollow fiber braided tube, hollow fiber desalination membrane and preparation method thereof

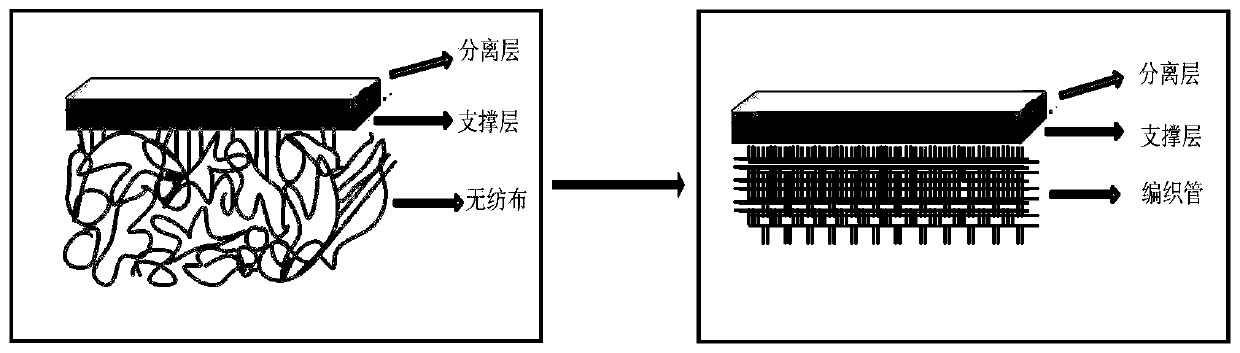

A technology of desalting membrane and braided tube, which is applied in the field of membrane separation, can solve the problems of uneven coating of the ultrafiltration membrane forming system, easy trapping in the desalting membrane of the separator, and desalination rate of the defective desalting membrane, etc., and achieves improved mechanical properties and regular surface Effect of smoothing and reducing film defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

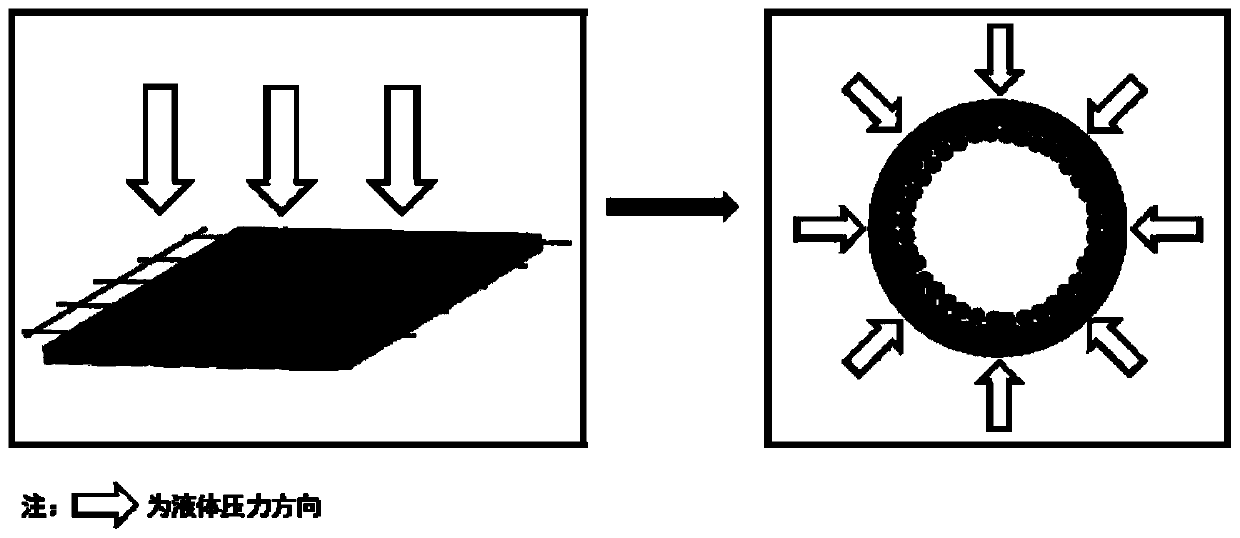

Method used

Image

Examples

Embodiment 1

[0031] The braided tube (made of polyethylene terephthalate) treated by singeing process was selected to be coated with polyvinylidene fluoride ultrafiltration membrane as the base membrane, and one side of the treated base membrane was immersed in m-phenylenediamine aqueous solution (mass concentration 2.5%), fully contact with trimesoyl chloride / n-hexane solution (mass concentration 1.5%) after draining, perform interfacial polymerization reaction, and finally perform heat treatment, wash away residual reactants with deionized water to obtain low-defect hollow fiber desalination membrane. After the membrane is treated, its desalination rate is tested, and the results show that when the singeing process is used as the base lining, the desalination rate reaches 99%.

Embodiment 2

[0041] Select the braided tube (polytetrafluoroethylene) treated by the singeing process to coat the polyethersulfone ultrafiltration membrane as the base membrane, immerse the treated base membrane on one side in the piperazine aqueous solution (mass concentration 5%) to fully contact, After draining, carry out interfacial polymerization reaction with trimesoyl chloride / n-hexane solution (mass concentration: 3%), and finally perform heat treatment, and wash away residual reactants with deionized water to obtain a low-defect hollow fiber desalination membrane. After the membrane is treated, it is tested that its desalination rate is 98%. The hollow fiber desalination membrane module was prepared by using the hollow fiber desalination membrane, and the module was continuously filtered with 2g / L MgSO4 solution at 10MPa for 10 hours, and then the desalination rate of the module was tested, and the desalination rate reached 96%.

[0042] Comparative Example 1

[0043] Select the co...

Embodiment 3

[0047] The braided tube (polyacrylonitrile) treated by singeing process is selected to be coated with polyvinyl chloride ultrafiltration membrane as the base membrane, and one side of the treated base membrane is immersed in diethylenetriamine aqueous solution (mass concentration 0.1%) to fully contact , after draining, carry out interfacial polymerization reaction with trimesoyl chloride / n-hexane solution (mass concentration 0.05%), and finally perform heat treatment, and wash away residual reactants with deionized water to obtain a low-defect hollow fiber desalination membrane. The desalination rate was tested after the membrane was treated, and the results showed that the desalination rate reached 98% when the braided pipe treated with singeing process was used as the base lining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com