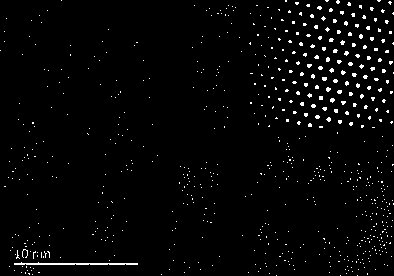

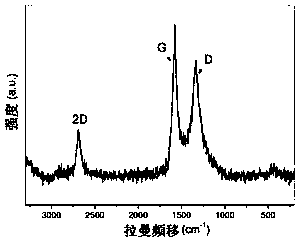

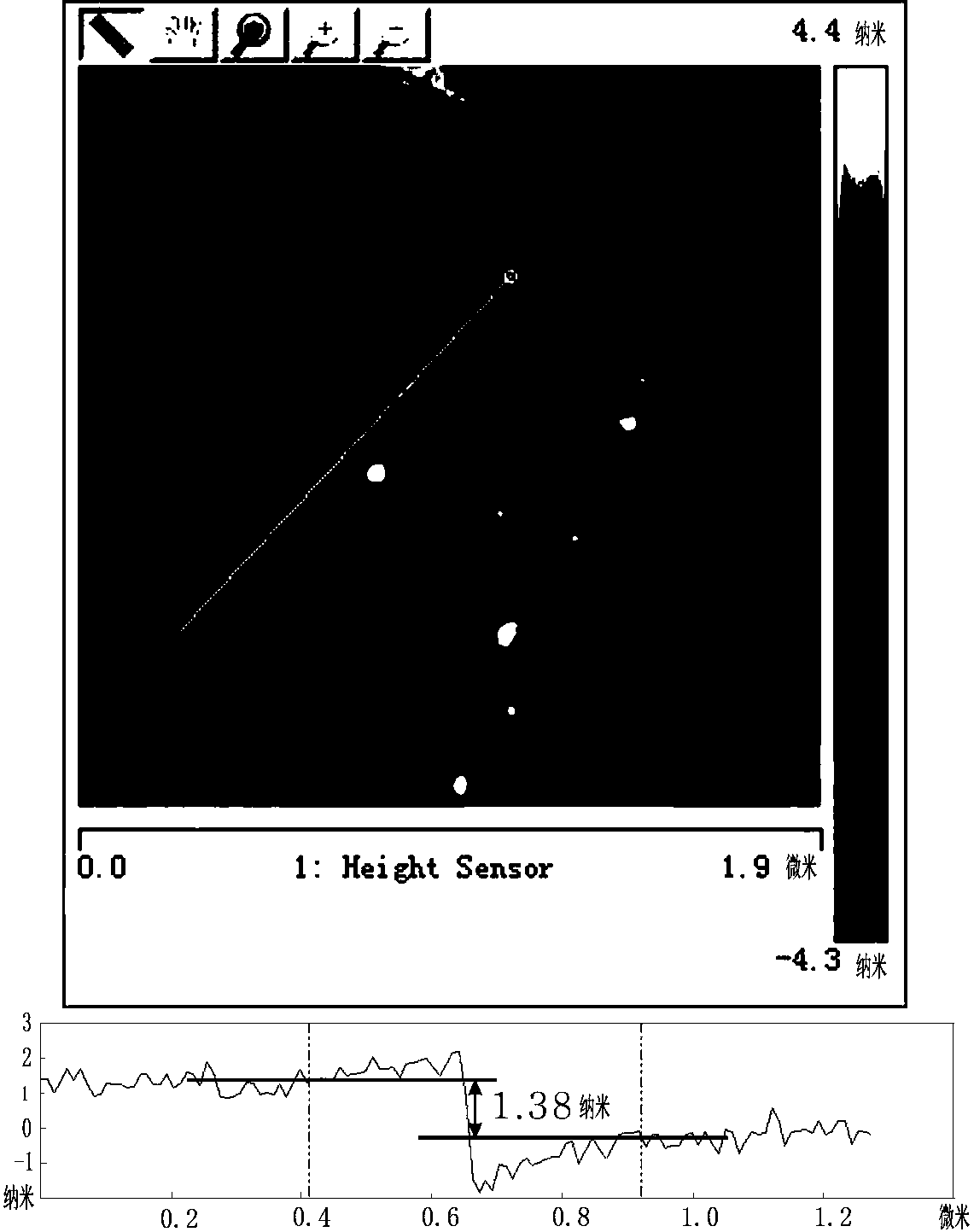

Preparation of high-quality graphene with plant film layer and preparation method thereof

A high-quality, graphene technology, applied in the field of graphene, to achieve the effect of low cost, large industrial promotion value, and improved flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Soak 5 g of Magnolia petals in 100 mL of distilled water for 10 minutes to wash away the floating dust, make a mixture of ethanol and ultrapure water at a volume ratio of 1:3, and use hydrochloric acid to adjust the pH to 4. Use this mixture Soak Magnolia petals in 100 mL solution for 48 h;

[0040] Step 2: Take out the soaked Magnolia petals, put them in 100 mL of 10% glucose solution, soak them for 24 h, and then put them in an ultrasonic microwave synthesizer, with microwave frequency of 2450 MHz and ultrasonic frequency of 18 KHz React for 20 minutes;

[0041] Step 3: Use a 50 mL centrifuge tube at 8000 r / min to centrifuge the treated Magnolia petals from the glucose solution, and wash them several times with ultrapure water, spread them flat on a petri dish, and set them at 40 ℃ oven, dry for 10 hours;

[0042] Step 4: Put the dried plant film into a corundum porcelain boat, place it in a tube furnace, protect it with nitrogen, raise the temperature to 70...

Embodiment 2

[0047] Step 1: Soak 5 g of cherry blossom petals in 100 mL of distilled water for 10 minutes to wash off the floating dust, make a mixture of ethanol and ultrapure water at a volume ratio of 1:3, and use hydrochloric acid to adjust the pH to 4. Use this mixture 100 mL soaked cherry blossom petals for 36 h;

[0048] Step 2: Take out the soaked cherry blossom petals, put them in 120 mL of 10% glucose solution, soak them for 24 h, then put them in an ultrasonic microwave synthesizer, react with 2450 MHz microwave frequency and 15 KHz ultrasonic frequency 20min;

[0049] Step 3: Use a 50 mL centrifuge tube at 8000 r / min to centrifuge the treated cherry blossom petals from the glucose solution, and wash them several times with ultrapure water. Dry in an oven for 8 hours;

[0050] Step 4: Put the dried plant film into a corundum porcelain boat, place it in a tube furnace, protect it with nitrogen, raise the temperature to 700 °C at a rate of 2 °C / min, and keep it warm for 2 hours;...

Embodiment 3

[0053] Step 1: Soak 8 g of corn stalks in 100 mL of distilled water for 10 minutes to wash away the floating dust, make a mixture of ethanol and ultrapure water at a volume ratio of 1:3, and use hydrochloric acid to adjust the pH to 2. Use this mixture 180 mL of soaked straw for 48 h;

[0054] Step 2: Take out the soaked straw, put it in 160 mL of 3% glucose solution, soak it for 12 hours, then place it in an ultrasonic microwave synthesizer, and react it with microwave frequency of 2450 MHz and ultrasonic frequency of 25 KHz for 60 min ;

[0055] Step 3: Use a 50 mL centrifuge tube at 8000 r / min to centrifuge the treated straw out of the glucose solution and wash it several times with ultrapure water. In the oven, dry for 24 hours;

[0056] Step 4: Put the dried plant film into a corundum porcelain boat, place it in a tube furnace, protect it with nitrogen, raise the temperature to 900 °C at a rate of 2 °C / min, and keep it warm for 4 hours;

[0057] Step 5: After the calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com