Cathode material used for PETE device

A cathode material and device technology, which is applied in the direction of electrical components, chemical instruments and methods, and parts of discharge tubes/lamps, etc., can solve the problems of low electron emission rate and weak sunlight absorption ability, so as to improve electron emission rate, Facilitates absorption and increases the effect of scattering centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

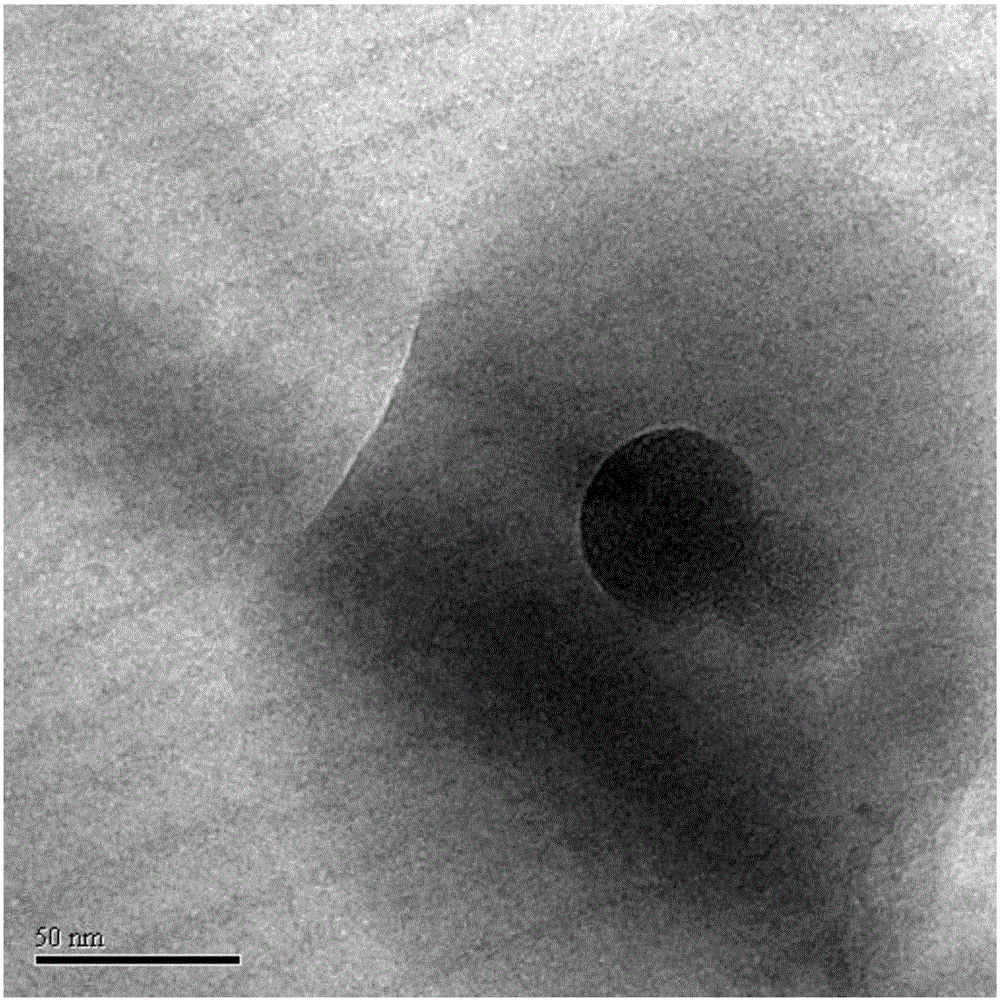

[0018] A kind of cathode material for PETE device, prepares Si 90 Ge 10 +0.05 mol% B sample. The cathode material for PETE devices selects silicon Si with a wide band gap and germanium Ge to form a binary solid solution compound material, and the compound is doped with element boron (B), and the molecular formula of the semiconductor compound formed is Si 90 Ge 10 +0.05 mol% B. Nanostructure formation method: adding boron nitride (BN) or carbon 60 (C 60 ) nanoparticles; the sintered material is cut into thin slices with a thickness of 2mm-5mm, and corroded in nitric acid with a concentration of 40%-80% at 80°C-120°C for 2min-5min. The material alloy is synthesized by intermediate frequency smelting, and the alloy is rapidly sintered by spark plasma sintering (SPS).

[0019] The cathode material for PETE devices has an electron work function of 4.32 eV at room temperature, which is lower than that of conventional B-doped Si materials (about 4.4 eV); the work function of sa...

Embodiment 2

[0021] A kind of cathode material for PETE device, prepares Si 90 Ge 10 Material samples with +0.05mol% B and 2vol% Al pore former added. The cathode material for PETE devices selects silicon Si with a wide band gap and germanium Ge to form a binary solid solution compound material, and the compound is doped with element boron (B), and the molecular formula of the semiconductor compound formed is Si 90 Ge 10 +0.05 mol% B. Nanostructure generation method: Add aluminum Al nanoparticles as a pore-forming agent in the alloy powder film, the addition ratio is 2vol%, and then cut the sintered material into thin slices with a thickness of 2mm-5mm, and place it at a concentration of 80°C-120°C It is corroded in 40%-80% nitric acid for 2min-5min; the material alloy is synthesized by intermediate frequency smelting, and the alloy is rapidly sintered by spark plasma sintering (SPS).

[0022] The cathode material for PETE devices has an electron work function of 4.08ev at room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com