Two-step method of producing glyceryl monostearate and glyceryl distearate with low free glycerol

A kind of glyceryl distearate, low free technology, applied to glyceryl distearate, two-step method to prepare low free glycerol single field, can solve the problems of increasing the use cost, the effect of use and the like, to reduce consumption, The effect of improving product quality and decreasing free glycerin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

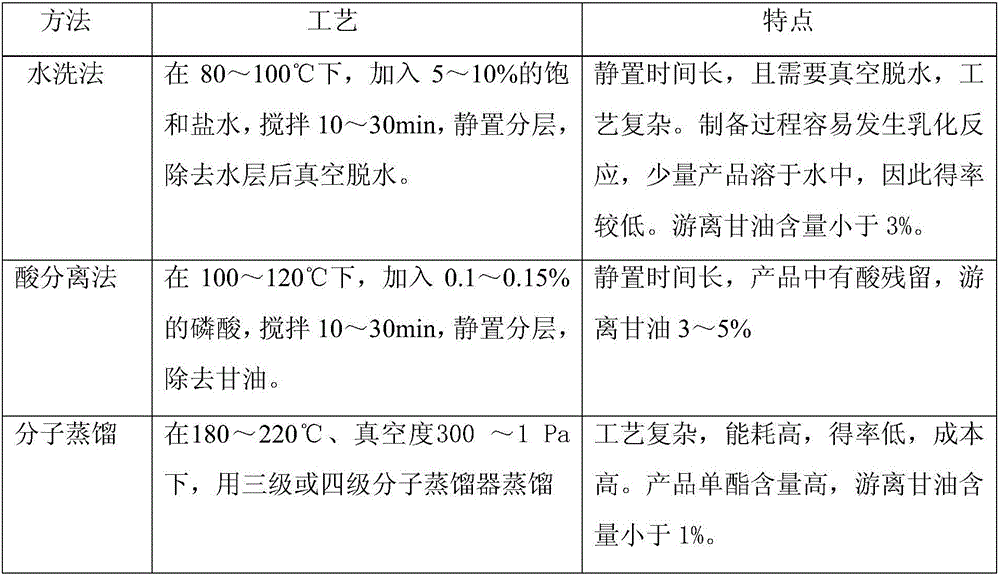

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 160g of glycerin and 0.8g of sodium hydroxide into the reactor equipped with heating, stirring, vacuum, and gas inlet and outlet devices, turn on the stirring, vacuum, and heating, and raise the temperature to 100°C with a vacuum of 0.09MPa to completely dissolve the sodium hydroxide in in glycerin.

[0033] Turn off the vacuum, add 650g of hydrogenated oil to react, pass in nitrogen and keep the nitrogen pressure at 0.08MPa; continue to heat up to 240°C, and react for 30 minutes; turn off the heating and start to cool down, while cooling down, slowly add 170g of hydrogenated oil at a uniform speed, and control the cooling rate to 3°C / min, at the end of the cooling, exactly 170g of hydrogenated oil has been added. After cooling down to 160°C, keep warm for 60 minutes, the reaction is over, and the product is obtained by cooling.

[0034] Example 1 Inspection data

[0035] project index Free glycerin, % 1.2 Acid value, mgKOH / g 1.5 Iodine...

Embodiment 2

[0037] Add 160g of glycerin and 1g of sodium hydroxide into the reactor equipped with heating, stirring, vacuum, and gas in and out devices, turn on stirring, vacuum, and heating, and raise the temperature to 100°C with a vacuum of 0.09MPa to completely dissolve the sodium hydroxide in the glycerin middle.

[0038] Turn off the vacuum, add 660g of hydrogenated oil to react, feed nitrogen and keep the nitrogen pressure at 0.08MPa; continue heating to 235°C, and react for 40min; turn off the heating and start to cool down, while cooling down, slowly add 170g of hydrogenated oil at a uniform speed, and control the cooling rate to 3°C / min, at the end of the cooling, exactly 170g of hydrogenated oil has been added. After cooling down to 150°C, keep it warm for 60 minutes, the reaction is over, and the product is obtained by cooling.

[0039] Embodiment 2 inspection data

[0040] project index Free glycerin, % 1.1 Acid value, mgKOH / g 1.6 Iodine value, g...

Embodiment 3

[0042] Add 170g of glycerin and 0.8g of sodium hydroxide into the reactor equipped with heating, stirring, vacuum, and gas inlet and outlet devices, turn on the stirring, vacuum, and heating, and raise the temperature to 100°C with a vacuum of 0.09MPa to completely dissolve the sodium hydroxide in in glycerin.

[0043] Turn off the vacuum, add 650g of hydrogenated oil for reaction, feed nitrogen and keep the pressure of nitrogen at 0.08MPa; continue to heat up to 230°C, and react for 60 minutes; turn off the heating and start to cool down, while cooling down, slowly add 180g of hydrogenated oil at a uniform speed, and control the cooling rate to 3°C / min, at the end of cooling, exactly 180g of hydrogenated oil has been added. After cooling down to 160°C, keep warm for 50 minutes, the reaction is over, and the product is obtained by cooling.

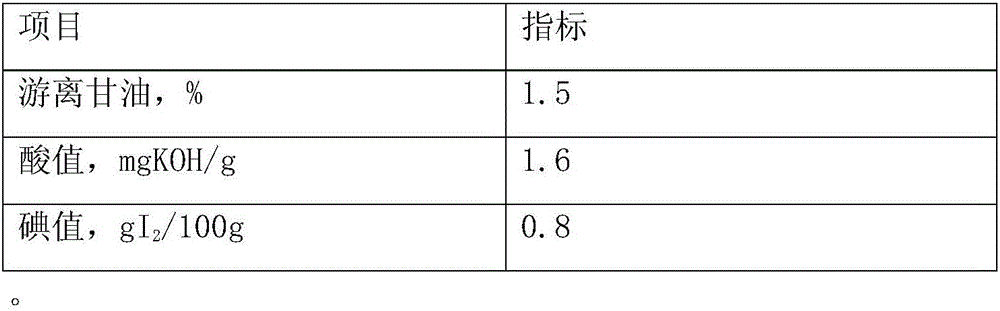

[0044] Embodiment 3 inspection data

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com