A kind of leaching agent and its preparation method and application

A technology of ore leaching agent and mine economics, applied in the field of ore leaching agent and its preparation, can solve the problems of poor rare earth leaching efficiency, high processing cost, instability, etc., reduce the amount of liquid and the processing capacity of subsequent processes, and improve the leaching of mother liquor Concentration, the effect of reducing the possibility of slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

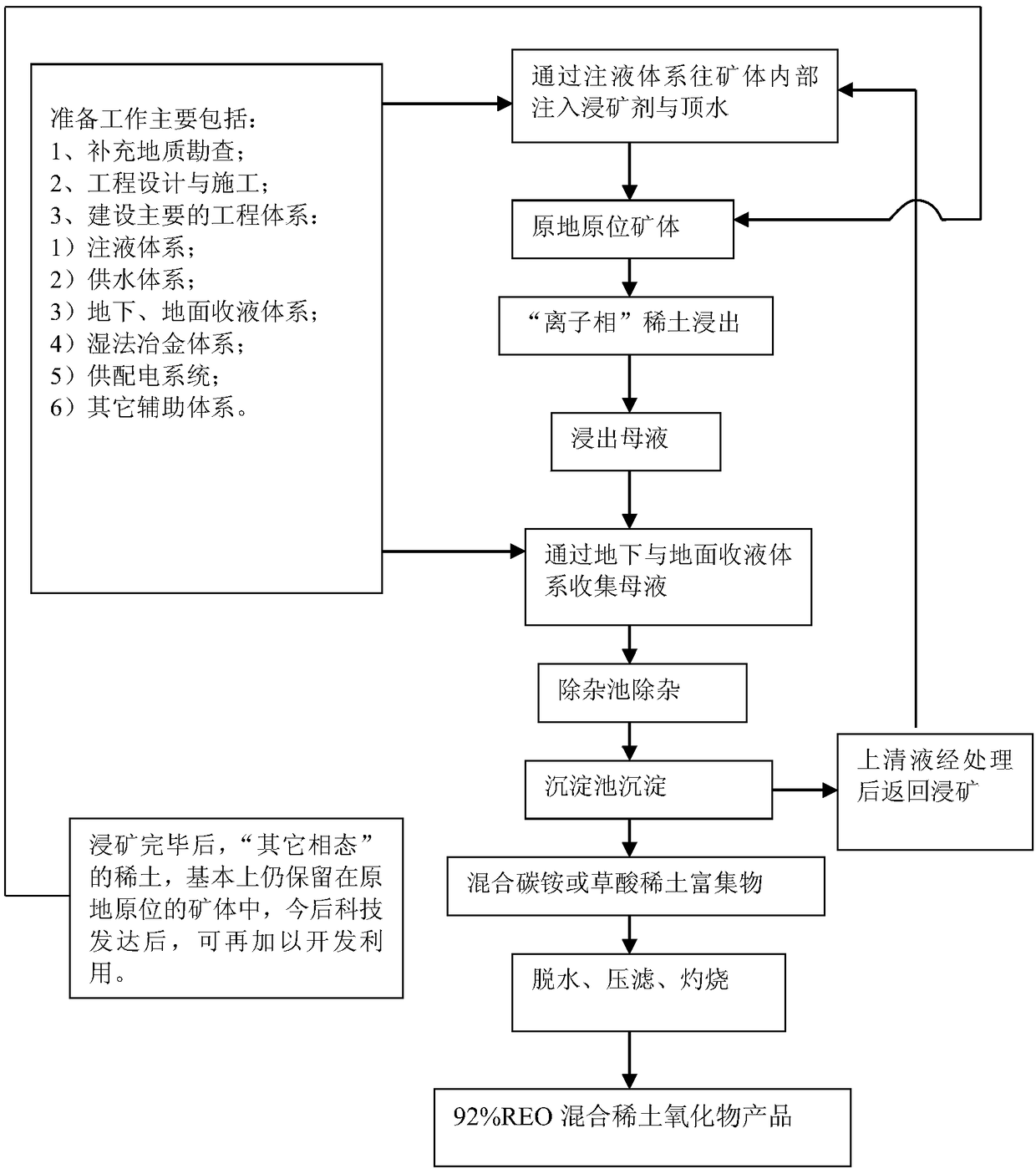

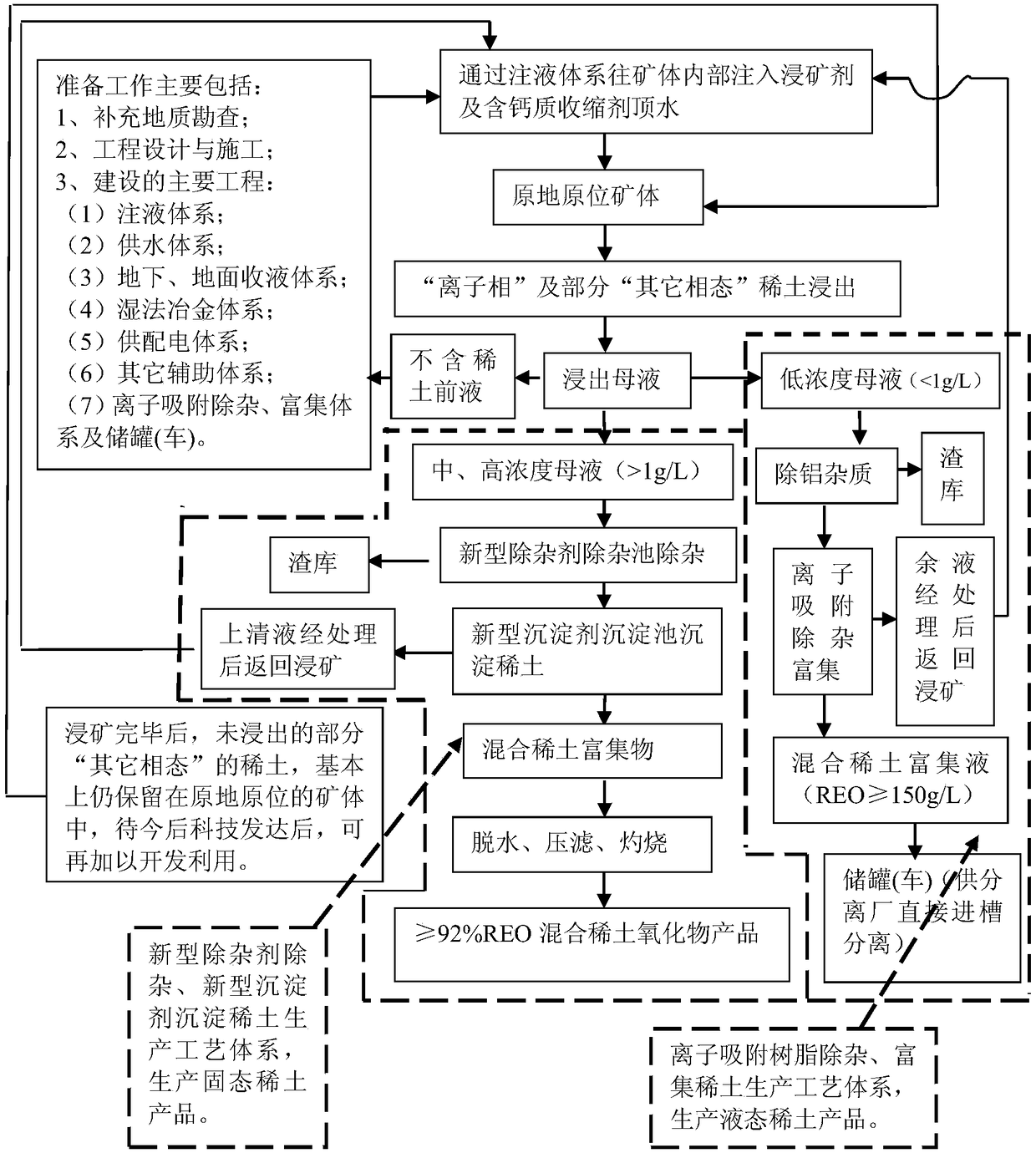

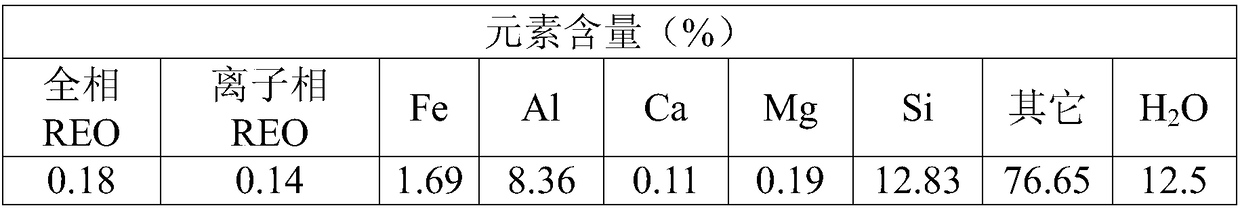

Method used

Image

Examples

Embodiment 1

[0059] The preparation of embodiment 1 liquid ore leaching agent

[0060] Crush the magnesite ore to a particle size of 0.125-0.15mm, adjust the slurry with water, and then add sulfuric acid to decompose until it becomes weakly acidic to obtain a liquid ore leaching agent. Wherein, iron<10%, manganese<3%, and calcium<10% in the magnesite, and the percentages are mass percentages. The obtained liquid ore leaching agent contains composite cations such as magnesium, iron, manganese and calcium.

Embodiment 2

[0061] The preparation of embodiment 2 solid leaching agent

[0062] After the liquid ore leaching agent prepared in Example 1 is filtered and washed, the obtained mother liquor is evaporated and crystallized to obtain a solid ore leaching agent. The solid leaching agent is convenient for storage and transportation.

[0063] In the process of ore leaching, the solid ore leaching agent can be redissolved with water or acid to obtain a liquid ore leaching agent, and then adjust the pH value to an appropriate range before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com