Carbon nitride hydrogel and preparation method thereof

A technology of carbon hydrogel and carbon nitride, applied in gel preparation, chemical instruments and methods, water treatment of special compounds, etc., can solve the problems of unfavorable hydrogel uniform growth, difficult to degrade basic dyes, etc., and achieve outstanding adsorption and degradation, simple and easy to operate, highlighting the effect of fluorescence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

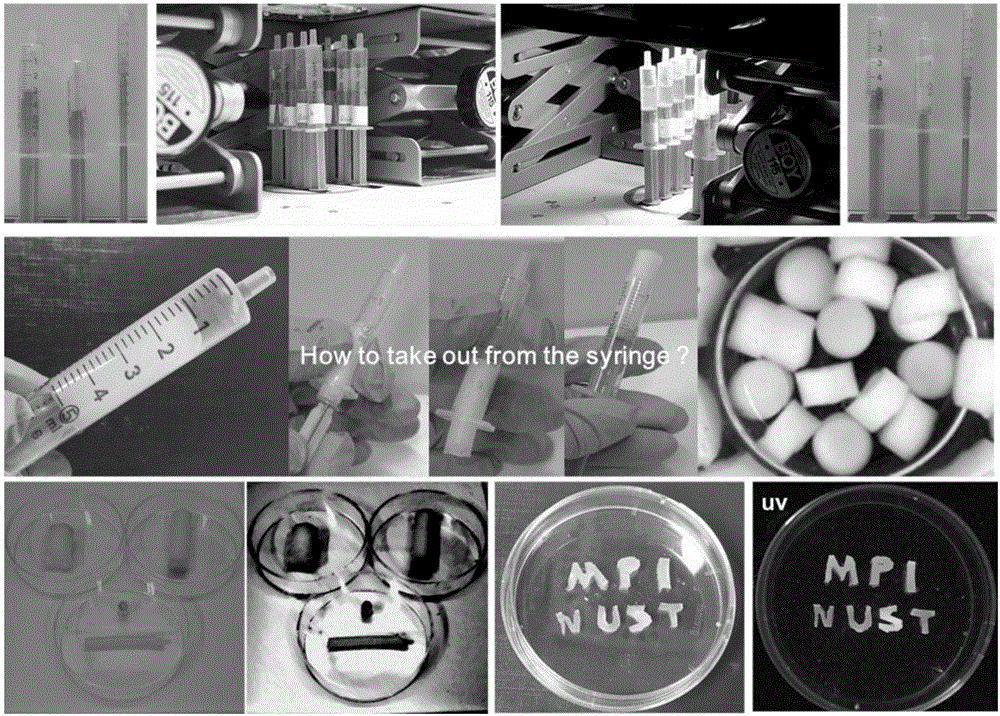

[0028] Step 1: ultrasonically disperse 1 mg of carbon nitride in 100 mL of deionized water for 24 h to obtain a carbon nitride aqueous solution;

[0029] In the second step, 400 mg of N,N-dimethylacrylamide and 4 mg of N,N'-methylenebisacrylamide were dissolved in 4.6 g of carbon nitride aqueous solution, and ultrasonicated for 5-10 minutes;

[0030] In the third step, nitrogen gas is passed into the above-mentioned mixed solution to replace the dissolved oxygen, and then a certain amount of mixed solution is drawn with a 5 ml cylindrical syringe;

[0031] The fourth step is to place the syringe vertically under a white LED lamp (power 50-200W), and keep a certain distance (5-10 cm) from the light source, and irradiate until the solution turns into a gel.

[0032] The preparation process adopted in the present invention is as figure 1 shown.

Embodiment 2

[0034] Step 1: ultrasonically disperse 2 mg of carbon nitride in 100 mL of deionized water for 24 h to obtain a carbon nitride aqueous solution;

[0035] In the second step, 400 mg of N,N-dimethylacrylamide and 4 mg of N,N'-methylenebisacrylamide were dissolved in 4.6g of carbon nitride aqueous solution and ultrasonicated for 5-10 minutes;

[0036] In the third step, nitrogen gas is passed into the above-mentioned mixed solution to replace the dissolved oxygen, and then a certain amount of mixed solution is drawn with a 5 ml cylindrical syringe;

[0037] The fourth step is to place the syringe vertically under a white LED lamp (power 50-200W), and keep a certain distance (5-10 cm) from the light source, and irradiate until the solution turns into a gel.

Embodiment 3

[0039] Step 1: ultrasonically disperse 3 mg of carbon nitride in 100 mL of deionized water for 24 h to obtain a carbon nitride aqueous solution;

[0040] In the second step, 400 mg of N,N-dimethylacrylamide and 4 mg of N,N'-methylenebisacrylamide were dissolved in 4.6g of carbon nitride aqueous solution and ultrasonicated for 5-10 minutes;

[0041] In the third step, nitrogen gas is passed into the above-mentioned mixed solution to replace the dissolved oxygen, and then a certain amount of mixed solution is drawn with a 5 ml cylindrical syringe;

[0042] The fourth step is to place the syringe vertically under a white LED lamp (power 50-200W), and keep a certain distance (5-10 cm) from the light source, and irradiate until the solution turns into a gel.

[0043] The fifth step is to study the photodegradation of the above-mentioned gel with dyes. The specific steps are as follows: cut the prepared hydrogel into a 0.5 mL cylinder, and then add 5 mL of methylene blue (MB) and me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com