Sn-Zr/SBA-15 mesoporous molecular sieve catalyst, and preparation method and application thereof

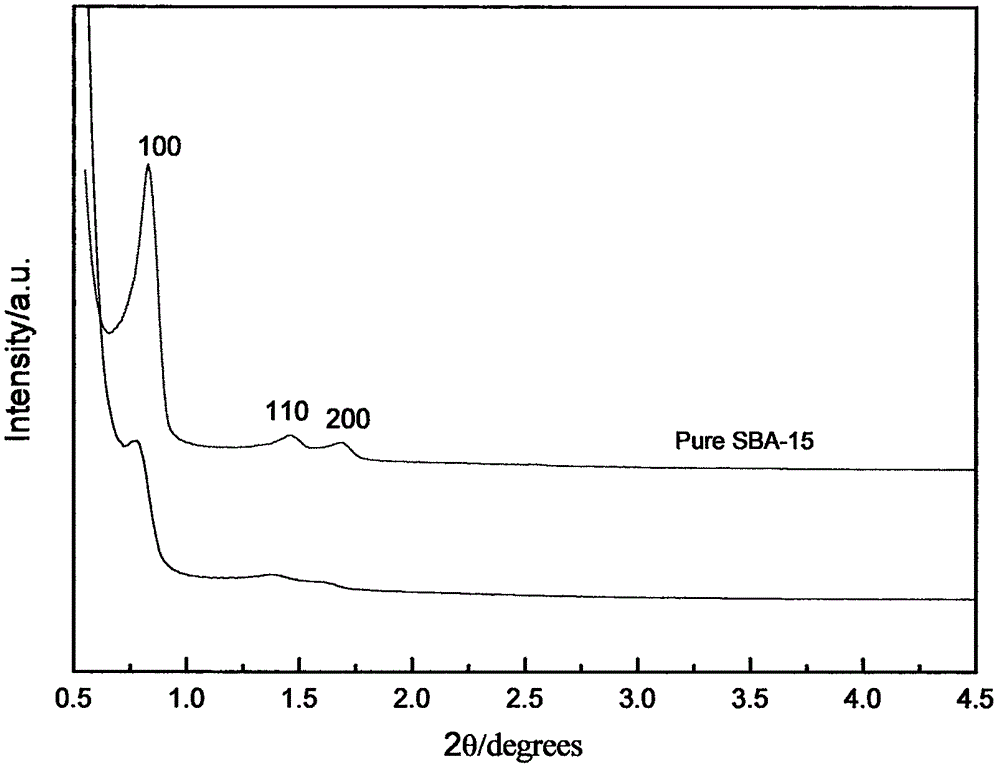

A mesoporous molecular sieve and catalyst technology, applied in the field of catalytic material preparation, can solve the problems of specific surface, pore volume and pore diameter reduction, and achieve the effects of low preparation cost, easy availability of preparation raw materials, good water resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

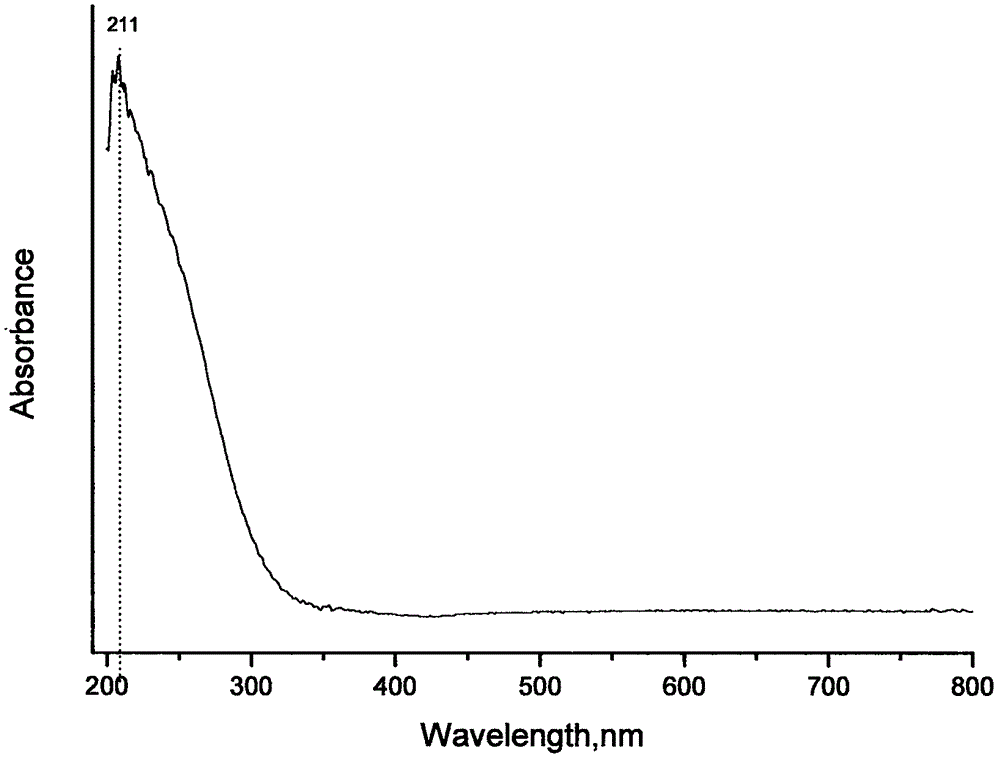

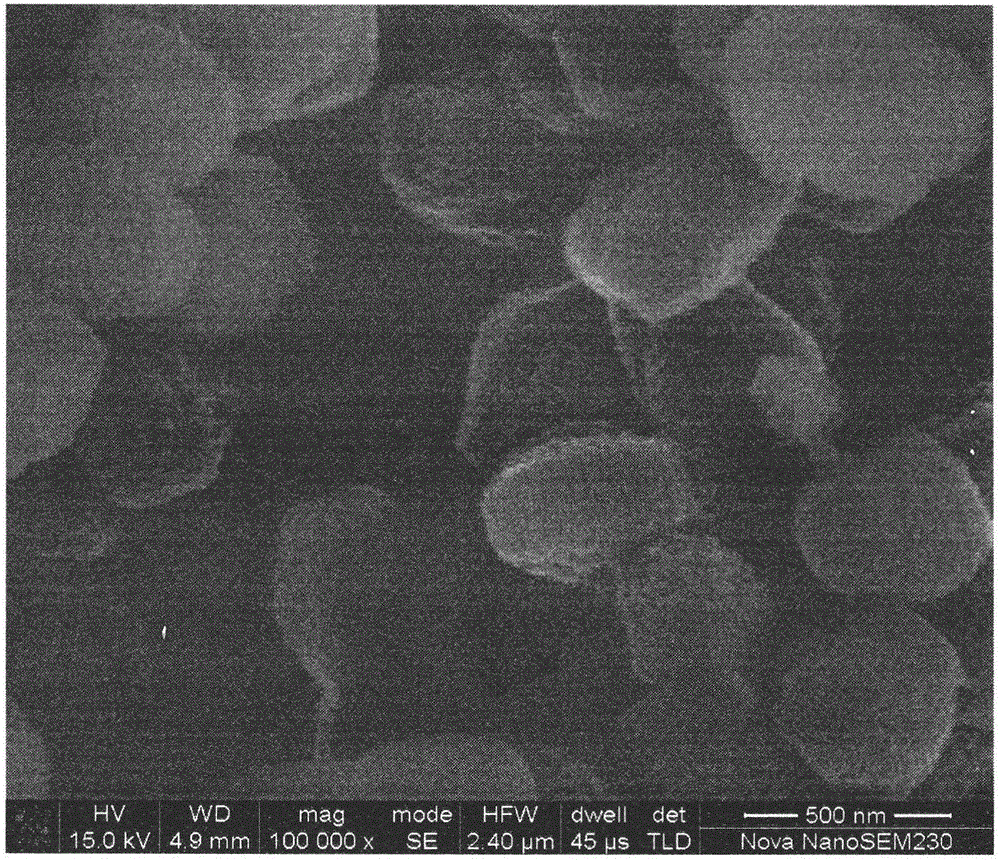

[0028] (1) Preparation of Sn-Zr / SBA-15 mesoporous molecular sieve

[0029] 10 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer is added to dissolve in the dilute hydrochloric acid aqueous solution of 500ml0.0319mol / l, add 1.1g zirconium oxychloride octahydrate again, at 38 Stir well at ℃ until the solution is clear and form mixture 1; add 1.9g of tin tetrachloride pentahydrate to 50ml of 0.0319mol / l dilute hydrochloric acid aqueous solution to dissolve, then add 22.5g of ethyl orthosilicate, and stir at 25℃ until clear, forming mixture 2; at 38°C, slowly add mixture 1 to mixture 2, in H 2 O and H + In a slightly acidic aqueous solution with a mass molar ratio of 1011:1, mix and stir for 24 hours to form a mixture 3; then transfer the mixture 3 to a polytetrafluoroethylene reactor, stand for crystallization at 100°C for 24 hours, filter, and The filter cake was washed with deionized water, dried at 60°C for 8 hours, then transferred to a m...

Embodiment 2

[0037] Embodiment 2: experimental procedure is the same as embodiment 1, and its difference is: when preparing mesoporous molecular sieve, zirconium oxychloride octahydrate is not added in the mixture 1, and the tin tetrachloride pentahydrate quality that dissolves with dilute hydrochloric acid aqueous solution is 3.8g, And it is not mixed with ethyl orthosilicate to form mixture 2, but it is directly added to mixture 1 with orthosilicate ethyl, at 40 ° C, H 2 O and H + Under the condition of slightly acidic aqueous solution with a mass molar ratio of 922:1, mixed and stirred for 24 hours, a Sn-SBA-15 catalyst without mesopore structure with a mass molar ratio of Sn and Si elements of 0.051:1 was prepared, which was used to catalyze phenol Formaldehyde alkylation reaction synthesizes bisphenol F product, and its mass yield is only 36.71%.

Embodiment 3

[0038] Embodiment 3: experimental procedure is the same as embodiment 1, and its difference is: when preparing mesoporous molecular sieve, be to use 125ml of 20 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer Dissolve in distilled water, stir and clarify, then add 375ml of 0.29mol / l hydrochloric acid aqueous solution without adding zirconium oxychloride octahydrate to form mixture 1, stir mixture 3 for 24h and crystallize at H 2 O and H + Under the condition of slightly acidic aqueous solution with a mass molar ratio of 280:1, the Sn-SBA-15 mesoporous molecular sieve catalyst with a mass molar ratio of Sn and Si elements of 0.039:1 is prepared, which is used to catalyze the alkylation reaction of phenol-formaldehyde Synthetic bisphenol F product, its mass yield is only 55.74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com