Metal or metalloid modified zinc cadmium sulfide-ethylenediamine photocatalyst and preparation method

An ethylenediamine light and metal modification technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of high photogenerated electron-hole recombination rate, high Poor photochemical stability, low photon efficiency, etc., to achieve the effects of good chemical stability, easy operation and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

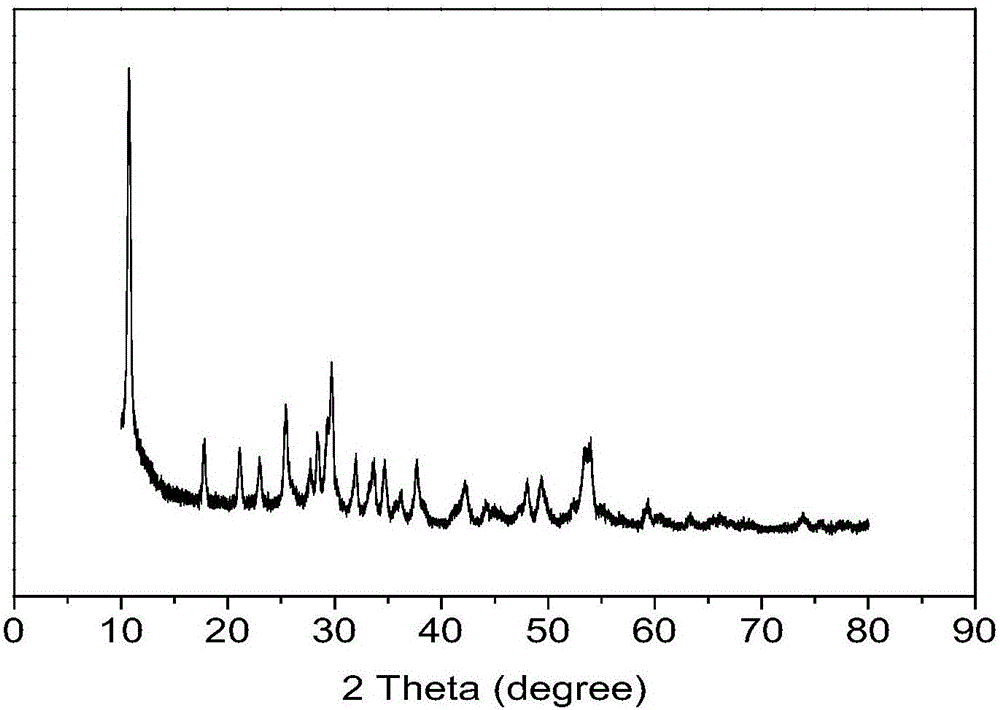

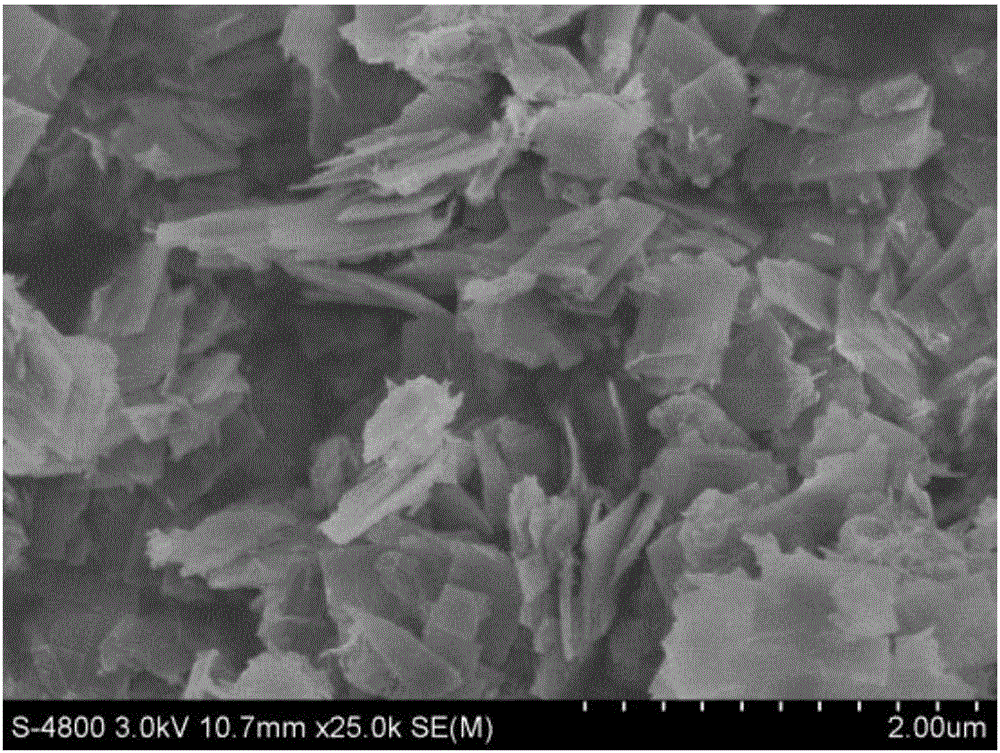

[0043] Example 1 Nickel-modified sulfur-zinc-cadmium (Ni / Zn 0.6 Cd 0.4 The preparation method of S)-ethylenediamine photocatalyst comprises the following steps:

[0044] (1) Mix cadmium acetate, zinc acetate and sulfur to urine in a molar ratio of 1:1.5:8 to obtain a mixture, take 5g of the mixture and add it to 100ml of ethylenediamine, stir to obtain a transparent solution, heat it in water at 180°C for 12h, and cool to room temperature, centrifuged, and the solid was washed with distilled water and dried to obtain Zn 0.6 Cd 0.4 S-ethylenediamine hybrid nanosheets;

[0045] (2) Add 2gZn 0.6 Cd 0.4 S-ethylenediamine hybrid nanosheets dispersed in 2ml 0.2M NiCl 2 In the aqueous solution, disperse evenly, and evaporate the water at 60°C to obtain Ni 2+ Modified Zn 0.6 Cd 0.4 S-ethylenediamine hybrid nanosheets;

[0046] (3) the Ni obtained by 2g step (2) 2+ Modified Zn 0.6 Cd 0.4 S-ethylenediamine hybrid nanosheets were dispersed in 50ml of deionized water, adding ...

Embodiment 2

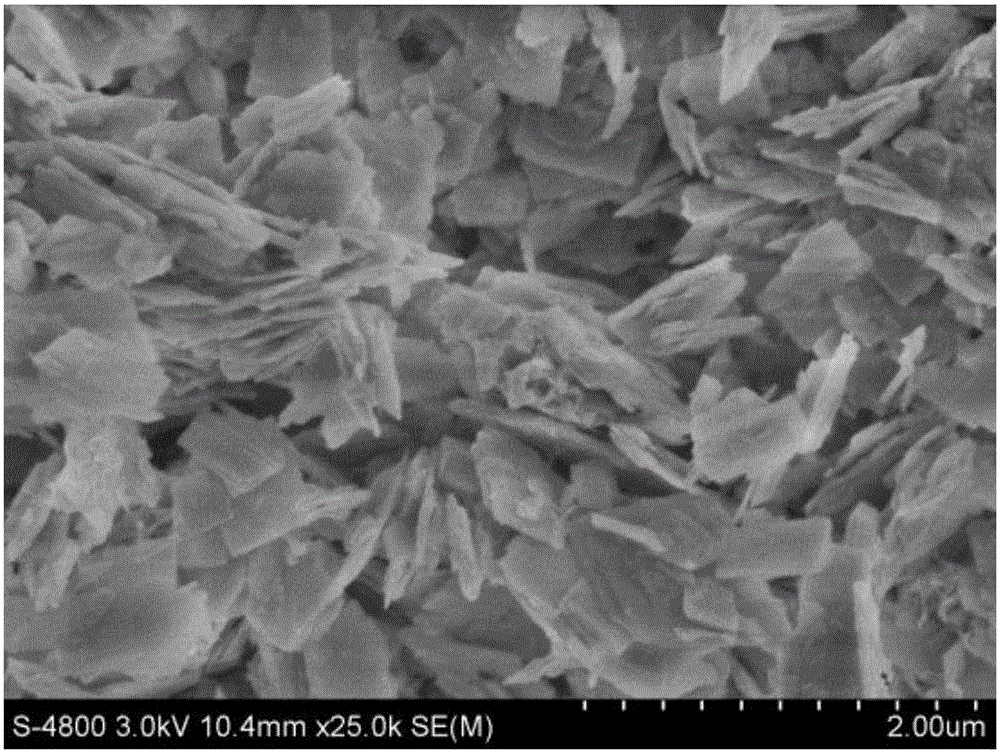

[0049] Example 2 Cobalt-modified sulfur-zinc-cadmium (Co / Zn 0.9 Cd 0.1 Preparation of S)-ethylenediamine photocatalyst

[0050] (1) Mix cadmium acetate, zinc acetate and sulfur to urine in a molar ratio of 1:9:30 to obtain a mixture, take 8g of the mixture and add it to 100ml of ethylenediamine, stir to obtain a transparent solution, heat it in water at 200°C for 36h, and cool to room temperature, centrifuged, and the solid was washed with distilled water and dried to obtain Zn 0.9 Cd 0.1 S-ethylenediamine hybrid nanosheets;

[0051] (2) 3gZn 0.9 Cd 0.1 S-ethylenediamine hybrid nanosheets dispersed in 3ml 0.4M CoCl 2 In the aqueous solution, the dispersion is uniform, and the water is evaporated at 70°C to obtain Co 2+ Modified Zn 0.9 Cd 0.1 S-ethylenediamine hybrid nanosheets;

[0052] (3) 3gCo 2+ Modified Zn 0.9 Cd 0.1 S-ethylenediamine hybrid nanosheets were dispersed in 50ml of deionized water, adding NaOH to adjust the pH to 13, heating to 70°C, adding 0.3g o...

Embodiment 3

[0056] Example 3 NiCo / Zn 0.8 Cd 0.2 Preparation of S-ethylenediamine photocatalyst

[0057] (1) Mix cadmium acetate, zinc acetate, and sulfur to urine in a molar ratio of 1:4:15 to obtain a mixture, take 10 g of the mixture and add it to 100 ml of ethylenediamine, stir to obtain a transparent solution, heat at 220°C for 48 hours, and cool to room temperature, centrifuged, and the solid was washed with distilled water and dried to obtain Zn 0.8 Cd 0.2 S-ethylenediamine hybrid nanosheets;

[0058] (2) 5gZn 0.8 Cd 0.2 S-ethylenediamine hybrid nanosheets dispersed in 5ml 0.5M NiCl 2 and 0.5MCoCl 2 In the mixed aqueous solution, the dispersion is uniform, and the water is evaporated to dryness at 80°C to obtain Ni 2+ -Co 2+ Modified Zn0.8 Cd 0.2 S-ethylenediamine hybrid nanosheets.

[0059] (3) the Ni obtained by 5g step (2) 2+ -Co 2+ Modified Zn 0.8 Cd 0.2 S-ethylenediamine hybrid nanosheets were dispersed in 50ml of deionized water, adding NaOH to adjust the pH to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com