Preparation method of black phosphorus nano lamina for photocatalytic degradation of dye wastewater

A technology of nano-sheets and dye wastewater, applied in the field of nano-materials, can solve the problems of small amount of preparation by chemical vapor deposition, low yield of preparation by mechanical stripping, cumbersome operation, etc., to improve photocatalytic activity and stability, application The effect of high value and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing black phosphorus nanosheets for photocatalytic degradation of dye wastewater, specifically comprising the following steps:

[0034] (1) Preparation of multilayer black phosphorus:

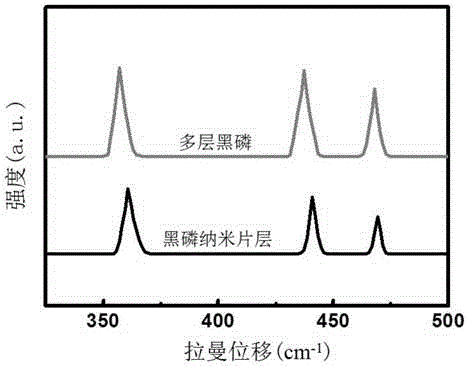

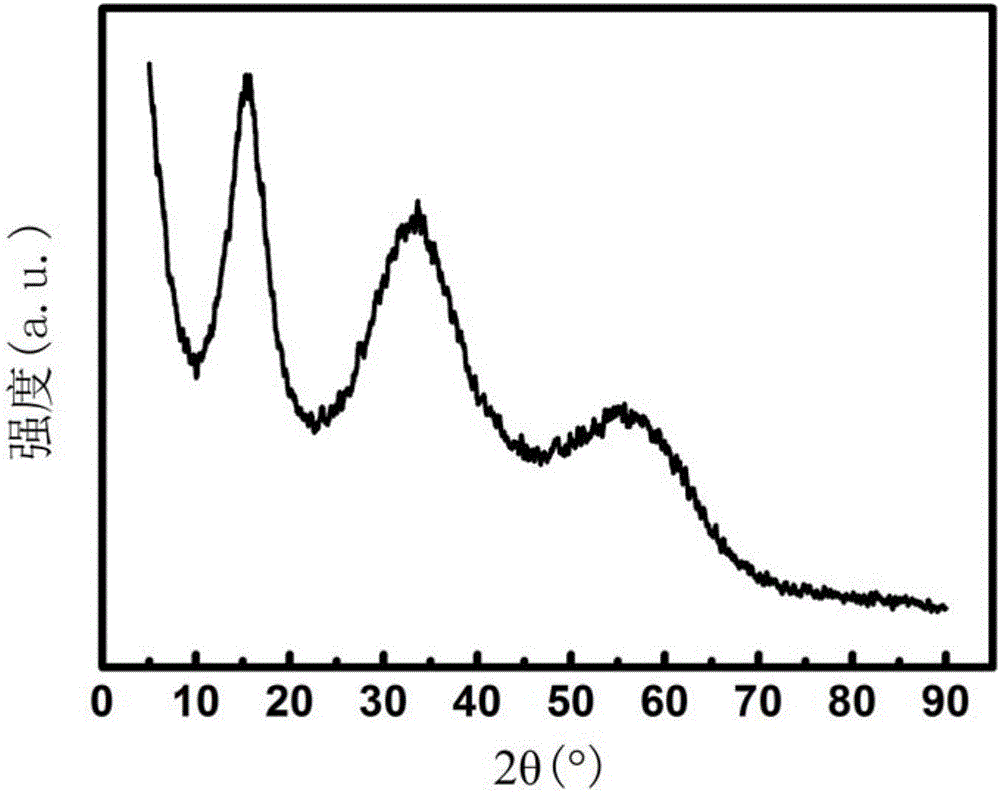

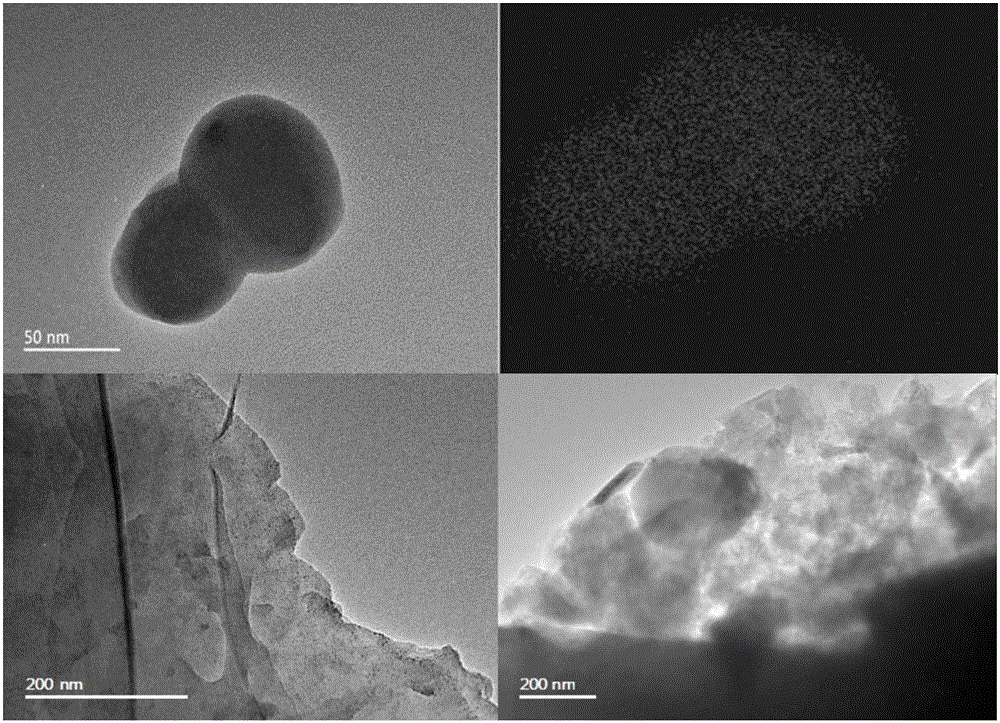

[0035] Using red phosphorus as a template, add 2g of red phosphorus and 15mL of ultrapure water into a 25mL hydrothermal kettle and steam at 200°C for 12 hours to remove the oxide layer on the surface of red phosphorus. Then take it out and dry it, grind it with an agate mortar for 0.8h to get the multilayer black phosphorus precursor, then put the multilayer black phosphorus precursor under the protection of argon at normal temperature and pressure for mechanical ball milling, ball milling for 30h, and keep the rotation speed at 500r / min. Multi-layer black phosphorus can be obtained after mechanical ball milling.

[0036] (2) Preparation of black phosphorus nanosheets:

[0037] Add multi-layer black phosphorus and surfactant into ultrapure water at a mass ratio of...

Embodiment 2

[0044] A method for preparing black phosphorus nanosheets for photocatalytic degradation of dye wastewater, the method specifically comprising the following steps:

[0045] (1) Preparation of multilayer black phosphorus: add red phosphorus and ultrapure water into a hydrothermal kettle, add 0.1g of red phosphorus per 1mL of water, and then react at 190°C for 15h. After the reaction, take out the solid , after drying, the red phosphorus with the surface oxide layer removed is obtained; the red phosphorus with the surface oxide layer removed is placed in a mortar and ground for 0.5h to obtain a multilayer black phosphorus precursor, and then the multilayer black phosphorus precursor is rotated at a speed of 400r / Mechanical ball milling under min, and filled with argon for protection at the same time, to prevent the multi-layer black phosphorus precursor from being oxidized, after 48 hours, the multi-layer black phosphorus is obtained;

[0046] (2) Preparation of black phosphoru...

Embodiment 3

[0048] A method for preparing black phosphorus nanosheets for photocatalytic degradation of dye wastewater, the method specifically comprising the following steps:

[0049] (1) Preparation of multi-layer black phosphorus: add red phosphorus and ultrapure water into a hydrothermal kettle, add 0.2g of red phosphorus per 1mL of water, and then react at 210°C for 10h. After the reaction, take out the solid , after drying, the red phosphorus with the surface oxide layer removed is obtained; the red phosphorus with the surface oxide layer removed is placed in a mortar and ground for 1 hour to obtain a multilayer black phosphorus precursor, and then the multilayer black phosphorus precursor is heated at a speed of 600r / min Under mechanical ball milling, at the same time filled with argon for protection, to prevent the multi-layer black phosphorus precursor from being oxidized, after 24 hours, the multi-layer black phosphorus is obtained;

[0050] (2) Preparation of black phosphorus n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com