Beta-cyclodextrin compound, preparation method thereof, and application thereof in water treatment

A technology of cyclodextrin and compound, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of low surface area and poor adsorption performance, and achieve a wide range of uses, no performance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

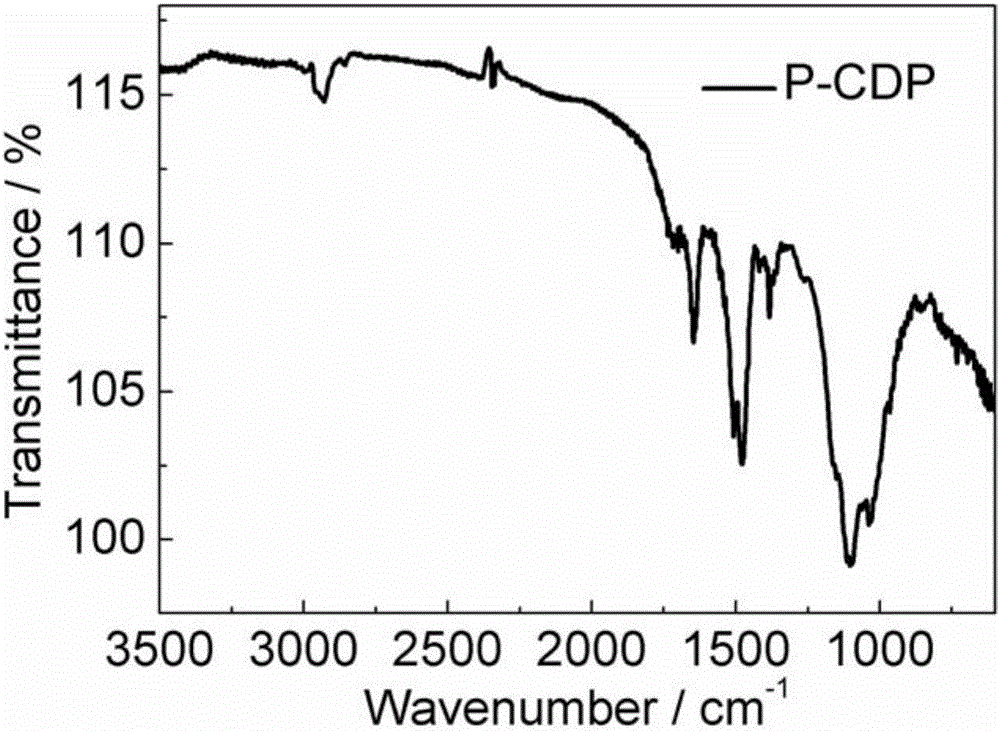

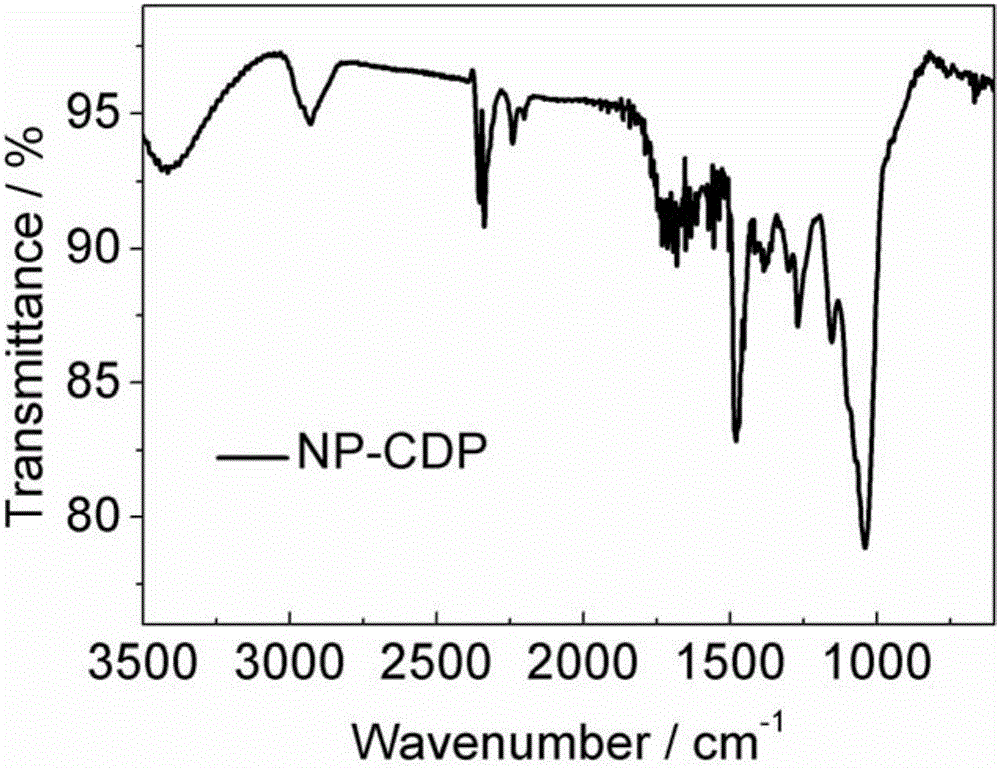

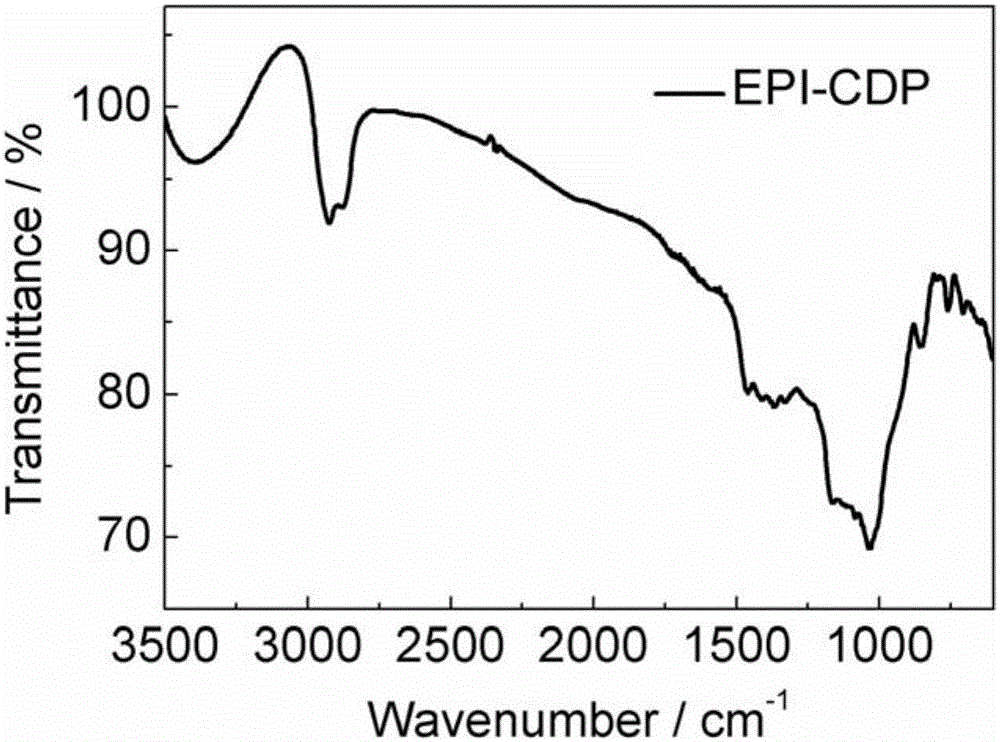

[0033] Embodiment 1, preparation porous β-cyclodextrin polymer (P-CDP)

[0034] A. Add 0.1g of carbon nitride to 20ml of NaOH (3mol / L) aqueous solution, perform an activation reaction at 60°C for 24 hours, and filter to obtain activated carbon nitride;

[0035] B. Mix 0.200g β-cyclodextrin, 50μl cross-linking agent pentafluoropyridine and 0.300g basic compound K 2 CO 3 Add it into 8ml tetrahydrofuran (THF), pass nitrogen for 5 minutes, carry out the first substitution reaction at 85°C for 48 hours, then add activated carbon nitride, and carry out the second substitution reaction for 24 hours. The resulting orange suspension was cooled and filtered, and the solid on the filter paper was washed with 1mol / L hydrochloric acid to remove residual K 2 CO 3 , until CO 2 After the release is complete, wash the obtained solid with 10ml of deionized water, 10ml of tetrahydrofuran, and 15ml of dichloromethane in sequence, then dry the solid in a high vacuum, 77K liquid nitrogen bath f...

Embodiment 2

[0037] Embodiment 2, P-CDP adsorption bisphenol A experiment

[0038] Mix 3 mg of the β-cyclodextrin polymer P-CDP obtained in Example 1 with 3 ml of 0.1 mM bisphenol A solution, stir for 1 h, take out the mixture with a syringe, filter it with an inorganic membrane filter, and measure the sample by UV-vis ultraviolet-visible spectroscopy The residual concentration of bisphenol A in water can remove bisphenol A and 90% in water within 5 minutes.

[0039] Sonicated β-cyclodextrin complexes were soaked in ethanol, and the β-cyclodextrin complexes could be regenerated. The experiment cycled 3 times, and the polymer had no performance loss.

Embodiment 3

[0040] Embodiment 3, P-CDP adsorption trichlorophenol experiment

[0041] Mix 3 mg of the β-cyclodextrin polymer P-CDP obtained in Example 1 with 3 ml of 0.1 mM trichlorophenol solution, stir for 1 h, take out the mixture from the syringe, filter it with an inorganic membrane filter, and measure the sample by UV-vis ultraviolet-visible spectroscopy The residual concentration of trichlorophenol in water can remove 90% of trichlorophenol in water within 5 minutes.

[0042] The polymer can be regenerated by soaking the ultrasonic β-cyclodextrin complex in ethanol. The experiment cycled 3 times, and the β-cyclodextrin complex had no performance loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com